Have you ever wondered how metal parts are made? A metal lathe is a fantastic machine that shapes and cuts metal. It spins the metal while tools carve it into the right shape. But did you know that some lathe operators improve their work with cool gadgets?

One such gadget is the quick change tool post. Imagine being able to switch tools in a flash! That’s what this tool does. It saves time and makes metalwork smoother. Many skilled people use lathe CAD files to design the perfect tool post.

These CAD files help you visualize and create the quick change tool post. They are great for anyone wanting to improve their lathe setup. Whether you’re a beginner or an expert, having the right resources can make all the difference.

So, why not explore how lathe CAD files can enhance your metal lathe experience? You might find new ways to make your projects easier and more fun!

Lathe Cad Files For Metal Lathe Quick Change Tool Post

Lathe CAD Files and Quick Change Tool Posts

Lathe CAD files are essential for anyone using a metal lathe. They help create a quick change tool post, making your work much smoother. Imagine how fast you could switch tools without wasting time! This setup improves efficiency and accuracy. Plus, it allows for more creativity in your projects. Did you know that having the right tool setup can cut your project time in half? Discover the world of lathe CAD files and unlock your full potential today!Understanding Lathe CAD Files

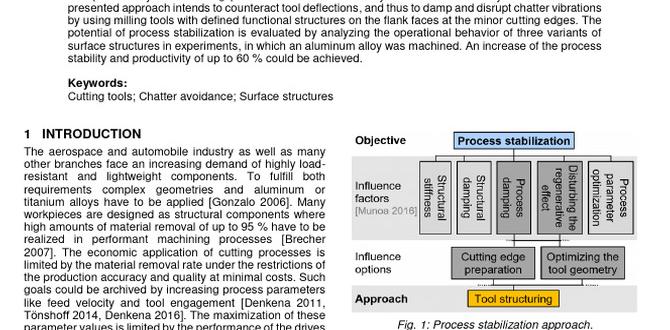

Definition and importance of CAD files in lathe design. Common formats and software used for creating lathe CAD files.CAD files help us design and build things like lathes. They are like digital blueprints that show how everything fits together. These files make building a lathe easier and less confusing. Popular formats for CAD files include DXF and DWG, and software like AutoCAD or Fusion 360 are great for creating them. Remember, using CAD files is like having a treasure map, guiding you to the shiny gold of successful lathe construction!

| CAD File Format | Common Software |

|---|---|

| DXF | AutoCAD |

| DWG | Fusion 360 |

| STL | TinkerCAD |

Benefits of a Quick Change Tool Post

Increase in efficiency and productivity in metalworking. Enhanced precision and versatility for various machining tasks.A quick change tool post brings many benefits to metalworking. It helps workers finish tasks faster and more accurately. With this tool, you can switch tools quickly without wasting time. This leads to increased efficiency and higher productivity. You can also do different machining jobs easily. Here’s how:

- Efficiency: Save time by changing tools quickly.

- Precision: Achieve more accurate cuts and shapes.

- Versatility: Use for various tasks without hassle.

How does a quick change tool post improve metalworking?

A quick change tool post boosts productivity by reducing setup time and increasing accuracy. This means more work gets done in less time, helping builders create better products with ease.

Key Features of a Quick Change Tool Post

Adjustable settings for different tool heights and sizes. Robust construction and materials for durability.A quick change tool post offers some cool features. First, you can adjust it to fit different tool heights and sizes. This makes changing tools super easy, like swapping shoes for different races! Plus, these tool posts are built tough. They can handle hard work without falling apart. If tools could talk, they’d probably say, “I’m in it for the long haul!” Here’s a quick look at its features:

| Feature | Description |

|---|---|

| Adjustability | Fits various tool heights |

| Durability | Sturdy materials for long life |

Downloading and Accessing Lathe CAD Files

Websites and repositories offering free and paid CAD files. Tips for ensuring compatibility with your specific lathe model.Finding the right lathe CAD files can feel like searching for a needle in a haystack—if that needle could also turn into a funky tool post! Luckily, many websites offer both free and paid options. Popular sites include Thingiverse and GrabCAD. But wait! Before clicking that download button, check that the file matches your lathe model. Compatibility is key, unless you enjoy DIY puzzles! Here’s a handy table to help:

| Website | Free/Paid | Notes |

|---|---|---|

| Thingiverse | Free | Great community uploads! |

| GrabCAD | Free | Professionally made files. |

| eBay | Paid | Unique finds if you’re lucky! |

By ensuring compatibility, you’ll save yourself from the great CAD chase. Happy downloading!

Steps to Design Your Own Quick Change Tool Post

Essential measurements and specifications required for design. Stepbystep guide to creating your CAD file based on your lathe.To create your own quick change tool post, start with important measurements. You need the lathe’s swing, distance between centers, and tool holder size. Pay close attention to accuracy! Take each measurement carefully. Then, follow these steps to design your CAD file:

- Choose the right software.

- Create a new project and set units.

- Draw the base and tool holder.

- Add features like clamps and adjustments.

- Review and save your design.

This process makes it easier to create and use your tool post, fitting neatly on your lathe.

What materials should I use for my quick change tool post?

Use strong materials like steel or aluminum. They are durable and can handle heavy cuts. Selecting the right material ensures your tool post lasts longer.

Common Mistakes to Avoid When Using CAD Files

Misinterpretation of dimensions and tolerances. Ignoring material properties and machining limitations.Using CAD files can be a fun adventure, but watch out for sneaky traps! One big mistake is misreading dimensions and tolerances. This can lead to parts that don’t fit or work well. Always double-check those numbers!

Another pitfall is ignoring what the materials can handle. Every material has its quirks, just like your quirky uncle at family gatherings. If you forget those properties, your project might flop. Always remember, the right material properties and the proper machining limitations can save your day and your project!

| Mistake | Tip |

|---|---|

| Misreading dimensions | Double-check before you cut! |

| Ignoring material limits | Know your materials like you know your friends! |

Stay sharp, and happy machining!

Real-World Applications of Quick Change Tool Posts

Examples of industries that benefit from quick change setups. Case studies highlighting improvements in workflow and output.Many industries enjoy the benefits of quick change tool posts. For instance, car manufacturing relies on these setups to switch tools faster, making the production line as smooth as a well-oiled machine. Fast tool changes can boost output by up to 40%, allowing workers to enjoy an extra coffee break or two!

In aerospace, companies can rapidly adjust their tools for different aircraft parts, improving workflow. One case study shows a factory reduced downtime by 30%. That’s like finding extra fries at the bottom of the bag! With quick change tool posts, productivity soars, making tasks easier and more efficient.

| Industry | Efficiency Improvement |

|---|---|

| Car Manufacturing | Up to 40% |

| Aerospace | 30% Reduced Downtime |

Future Trends in Lathe Technology and Tooling

Advancements in CAD technology for precision engineering. Emerging materials and tools improving lathe efficiency.New technology is changing how we use lathes. With CAD advancements, engineers can create detailed designs. This helps make parts that fit perfectly. Emerging materials also play a big role. Stronger and lighter materials help lathes work better and faster. Imagine a lathe that can go from zero to hero in seconds! Efficiency is the name of the game. Here’s a quick look at how the future is shaping up for lathes:

| Advancements | Impact on Lathe Efficiency |

|---|---|

| Precision CAD Tools | Improves accuracy |

| Lightweight Materials | Reduces wear and tear |

| Smart Technology | Enhances automation |

Conclusion

In summary, lathe CAD files for metal lathes can help you create a quick change tool post. These files make it easier to switch tools and improve your projects. We encourage you to explore available designs and start experimenting. By using CAD files, you can enhance your metalworking skills and make your tasks much simpler. Happy machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Cad Files For A Metal Lathe Quick Change Tool Post:Sure! Here are answers to some questions about lathe CAD files for a metal lathe quick change tool post: 1. **What is a CAD file?** A CAD file is a digital drawing of an object. It helps you design and understand how things fit together. 2. **Why do we need a quick change tool post?** A quick change tool post helps us switch tools fast while using a lathe. It saves us time and makes work easier. 3. **Can I find free CAD files online?** Yes! You can find free CAD files for tool posts on websites that share designs. Just search for what you need! 4. **How do I use a CAD file for a tool post?** You can open a CAD file in special software. Then, you can see the design and use it to make the tool post. 5. **What materials can I use to make a tool post?** You can make a tool post from strong materials like steel or aluminum. These materials last longer and are very sturdy.

Sure! Please give me a question to answer.

What Cad File Formats Are Commonly Used For Designing A Quick Change Tool Post For A Metal Lathe?We can use several CAD file formats to design a quick change tool post for a metal lathe. Some common ones are DWG, which is used by AutoCAD, and STL, which is good for 3D printing. Another format is STEP, which helps share designs between different software. Each format helps us create and share our designs easily!

How Can I Modify Existing Cad Files For A Quick Change Tool Post To Fit My Specific Metal Lathe Model?To change CAD files for your quick change tool post, first, open the file in CAD software. Next, measure your metal lathe to see what needs to change. You can then adjust the sizes or shapes in the file to make it fit. Save the new file and check it with your lathe. This way, you’ll have a tool post that works just right!

Are There Any Free Resources Or Repositories Where I Can Download Cad Files For Quick Change Tool Posts Designed For Metal Lathes?Yes, you can find free CAD files online for quick change tool posts. Websites like Thingiverse and GrabCAD have many designs you can download. Just search for “quick change tool post” on these sites. You can use these files to help your metal lathe. Enjoy creating!

What Are The Key Design Considerations When Creating A Cad File For A Quick Change Tool Post That Ensures Compatibility With Various Tooling Systems?When making a computer-aided design (CAD) file for a quick change tool post, you need to think about a few things. First, ensure the size fits many tools so they can all work together. Next, design the shape so tools can easily attach and detach. Also, check that the materials are strong but not too heavy. Finally, test the design with different tools to be sure everything works well together.

Can Printing Be Utilized To Create Prototypes Of Cad-Designed Quick Change Tool Posts For Metal Lathes, And What Materials Are Best Suited For This Purpose?Yes, we can use 3D printing to make prototypes of tool posts for metal lathes. This helps us test our designs quickly. Good materials for this are plastic or special types of resin. They are strong enough for testing. Once we are happy with the prototype, we can make it from metal for real use.