Lathe Cad Files For Metal Lathe Taper Turning Techniques

Exploring Lathe CAD Files for Metal Taper Turning

Lathe CAD files are essential for metalworking. They help create precise designs for taper turning on a lathe. Why is taper turning important? It allows for perfect fits in metal pieces, like making parts for machines or cars. Did you know that using these files can save time and reduce errors? As you learn to use lathe CAD files, you gain skills that can amaze your friends. Embrace the challenge and discover the world of metal lathe taper turning!Understanding Taper Turning in Metal Lathes

Definition of taper turning and its importance in metalworking. Common applications and industries utilizing taper turning.Taper turning is the process of creating a gradual change in diameter on a metal piece. This technique is important in metalworking because it helps create parts that fit together perfectly. Many industries, such as automotive and aerospace, use taper turning. It ensures that components work smoothly and fit tightly, leading to safer and more reliable machines.

- Used in making axles and shafts.

- Common in creating parts for airplanes.

- Helpful for making tools and molds.

What is the significance of taper turning?

Taper turning is essential for crafting precise machine parts, improving function, and enhancing safety.

Why is taper turning used in different industries?

Industries use taper turning to make sure parts fit well and function properly.

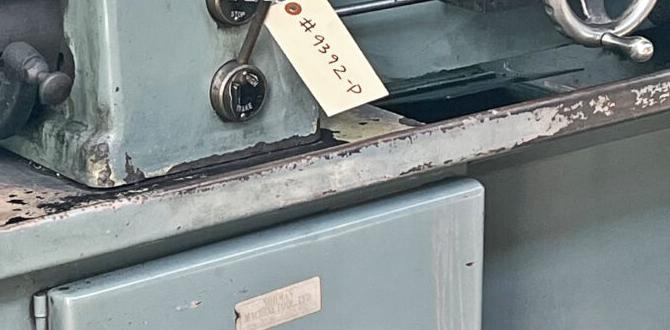

Essential Tools and Equipment for Taper Turning

List of tools required for taper turning on a metal lathe. Importance of choosing the right lathe for taper turning tasks.Taper turning on a metal lathe needs some special helpers! First, you’ll want a reliable metal lathe. This is the star of the show! A good cutting tool is also important; think of it like a magician’s wand – it shapes the taper. Don’t forget a tailstock for support. Let’s not skip a high-speed steel (HSS) tool or carbide inserts, which make cutting smooth and fun!

| Tool | Purpose |

|---|---|

| Metal Lathe | Main machine for taper turning |

| Cutting Tool | Shapes and cuts the metal |

| Tailstock | Provides extra support |

| High-Speed Steel Tool | Ensures smooth cuts |

| Carbide Inserts | Lasts longer and cuts better |

Picking the right lathe is like choosing the right pizza toppings – it can make or break the deal! A good lathe means better work and less fuss. So, gear up and let those taper turning dreams come true!

Designing and Creating Lathe CAD Files

Stepbystep process to create CAD files specific for taper turning. Recommended software options for generating lathe CAD files.Creating CAD files for taper turning can be an exciting adventure! Start by sketching your design on paper. It’s like drawing a treasure map—easy and fun. Next, use good software. Options like AutoCAD and Fusion 360 are popular among makers. With these tools, you can create precise models. Finally, export your design as a file. This step is like sending your creation into the big world of machines—it’s super thrilling!

| Software | Key Features |

|---|---|

| AutoCAD | Easy to use, great for 2D and 3D models. |

| Fusion 360 | Perfect for collaboration and advanced tools. |

Remember, your CAD file can make taper turning a breeze. After all, it’s not rocket science—it’s just lathe magic!

Best Practices for Taper Turning

Safety precautions and setup tips for successful taper turning. Techniques to achieve precision and accuracy during the tapering process.Starting taper turning safely is very important. Always wear safety glasses and gloves. Keep the workspace tidy. Make sure your lathe is properly set up. The machine should be level and securely fastened. To get a precise taper, use the following tips:

- Measure your workpiece carefully.

- Set the correct angle on your lathe.

- Tighten your tools securely before starting.

- Feed slowly to avoid mistakes.

Practice makes perfect! Take your time, and you’ll get better with each taper turning project.

What are the best safety precautions for taper turning?

Wear goggles and gloves, keep the workspace clean, and ensure the lathe is stable.

Common Challenges and Solutions in Taper Turning

Identification of frequent issues faced while taper turning. Proven solutions and tips to troubleshoot taper turning problems.Taper turning can be tricky. Common problems include uneven cuts, chatter, and tool wear. These issues can make your work look messy and waste materials. Here are some helpful tips to solve these problems:

- Adjust your tool height for a cleaner cut.

- Use a slower feed rate to reduce chatter.

- Inspect and replace dull tools regularly.

Fixing these issues can improve your taper turning results!

What are the common problems in taper turning?

Common issues include uneven surfaces, vibrations during cuts, and rapid tool wear. Keeping your tools sharp and adjusting your setup can help.

Resources for Finding Lathe CAD Files

Websites and platforms offering free or premium CAD files for taper turning. How to evaluate and choose quality CAD files for specific projects.Finding quality lathe CAD files can be a fun adventure! Websites like GrabCAD and Thingiverse offer both free and premium options for taper turning projects. Before downloading, evaluate the file by checking user ratings and the number of downloads. A good rule of thumb? If others like it, you probably will too! Remember, a neat and clear file will make your work smooth, unlike those tangled headphones you always find!

| Website | Free/Premium | Best For |

|---|---|---|

| GrabCAD | Free | Professional designs |

| Thingiverse | Free | Community projects |

| TurboSquid | Premium | High-quality models |

Case Studies: Successful Taper Turning Projects

Analysis of notable projects that utilized CAD files for taper turning. Lessons learned and insights from realworld implementations.Several projects have successfully used CAD files for taper turning. For instance, a team designed a sleek metal vase. They made it with precise dimensions from CAD files, showing how important accuracy is in taper turning. Another project crafted a beautiful table leg. It reminded everyone that CAD files are not just tools; they are your best friends in metalworking! The main lesson? Always double-check measurements to avoid unexpected surprises, like a table leg that looks like a pretzel!

| Project | Outcome | Lesson Learned |

|---|---|---|

| Metal Vase | Elegant design | Accuracy is key! |

| Table Leg | Beautifully crafted | Measure twice, cut once! |

Future Trends in Taper Turning Technology

Emerging innovations in taper turning and CAD technology. Predictions for the future of metal lathes and taper turning practices.Technology is always on the move, and taper turning is no exception. Exciting innovations are popping up everywhere! CNC machines are getting smarter, allowing for more precise cuts with less fuss. Picture a robot taking over the handle while you snack on donuts. Future metal lathes will likely be super easy to use and incredibly efficient. Imagine completing your projects in a snap! With CAD files advancing, designing your dream creations will feel like child’s play. Get ready for a world of possibilities!

| Innovation | Impact |

|---|---|

| CNC Technology | Increases precision and efficiency |

| Smart Software | Makes designs effortless |

| Automation | Reduces manual labor |

Conclusion

In summary, lathe CAD files help us design metal lathes, making taper turning easier and more precise. These files save time and improve accuracy. If you’re interested, explore CAD software to start your own designs. Practice using these tools to enhance your skills. Let’s create and innovate together in the world of metalworking!FAQs

What Are The Essential Cad File Formats For Designing Components For Taper Turning On A Metal Lathe?When designing parts for taper turning on a metal lathe, some important Computer-Aided Design (CAD) file formats are DXF, DWG, and STL. DXF stands for Drawing Exchange Format, which helps share drawings easily. DWG is used for storing two and three-dimensional designs. STL, or Stereolithography, is great for 3D printing. These formats help you create and share your designs with others.

How Can You Create Taper Turning Profiles In Cad Software To Ensure Accuracy During The Machining Process?To create taper turning profiles in CAD software, you start by drawing the shape you want. Use the tools to make one end wider and the other end thinner. Check the measurements to be sure they are correct. You can use guides or lines to help keep things straight. Finally, save your design so it’s ready for machining!

What Types Of Tooling And Setups Should Be Considered When Converting Cad Designs Into Practical Lathe Operations For Taper Turning?When you want to turn a taper on a lathe, you need the right tools. First, a good lathe with a taper attachment is important. You also need cutting tools that can shape the metal properly. Make sure to have a steady tool holder to keep everything in place. Lastly, check the setup often to ensure everything is working like it should.

What Are The Common Challenges Faced When Programming Taper Turning Operations In Cad Software For Metal Lathes?When you use CAD software to program taper turning, you might face a few problems. First, it can be tricky to set the right angles. If you make a mistake, the shape won’t look right. Also, sometimes the software doesn’t show the cuts clearly, which can confuse you. Lastly, figuring out the right speed and feed is important to avoid breaking tools. These challenges can make programming harder, but practice helps!

How Can You Optimize Cad Designs For Taper Turning To Minimize Waste And Enhance Efficiency In Metal Lathe Operations?To optimize CAD designs for taper turning, start by using the right tools and shapes. Make sure your design uses the least amount of material possible. You can do this by testing different angles and sizes in your design software. Always check if your design fits well on the metal so you don’t waste any. Also, clear shapes help the lathe work faster and better!