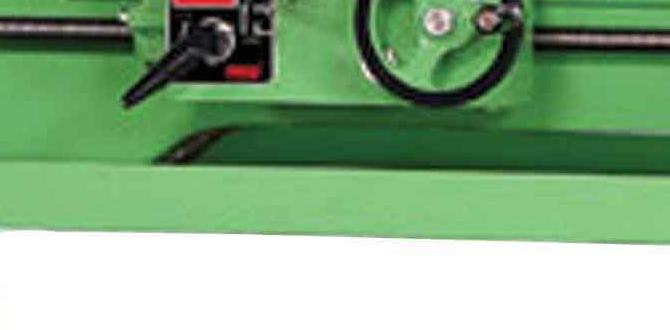

Have you ever wondered how metal pieces are shaped so perfectly? It often starts with a metal lathe. This incredible machine can cut, carve, and shape metal parts with great skill. A key part of using a lathe is having the right tools and files. That’s where lathe CAD files come into play.

Imagine opening a treasure chest filled with designs! These CAD files are like blueprints for creating amazing pieces on a lathe. They help you make everything from simple knobs to intricate gears. But what about the threading dial? This small but important tool helps you ensure that threads are cut correctly on your metal projects.

Do you want to learn how to use these tools more effectively? Discovering how to work with lathe CAD files and mastering the threading dial can change your projects forever. Get ready to dive into the exciting world of metalworking!

Lathe Cad Files: Metal Lathe Threading Dial Explained

Lathe CAD Files and Metal Lathe Threading Dials

Lathe CAD files offer detailed designs for metal lathe threading dials. These files help machinists create precise parts with ease. Do you ever wonder how dials make threading more accurate? With the right CAD file, you can model components and enhance your lathe skills. Fun fact: The threading dial often improves efficiency, allowing for perfect threads every time. Using these tools makes it simpler to achieve professional results in your projects.Understanding Lathe CAD Files

Definition and purpose of CAD files in machining. Types of CAD file formats commonly used in lathe designs.CAD files are special computer files used in machining. They show how to create parts with machines like lathes. These files help designers and engineers make accurate pieces quickly. There are different types of CAD file formats. Some common ones include:

- .DWG: Often used in engineering drawings.

- .DXF: Great for sharing designs.

- .STL: Common in 3D printing and modeling.

These formats make it easier to design and manufacture parts precisely. Understanding them can improve your machining skills.

What are CAD files used for in lathes?

CAD files help machinists design and plan parts for metal lathe threading dials. They create detailed blueprints, helping the machine make exact cuts. This leads to efficient and precise work.

Importance of Threading Dials in Metal Lathes

Functionality and benefits of threading dials in metal lathes. How threading dials enhance precision and ease of use.Threading dials are like the trusty sidekicks of metal lathes. They help you make perfect threads every time. Imagine trying to eat spaghetti without a fork—messy, right? That’s how difficult it can be without a threading dial! These dials improve precision and make everything so much easier. With a threading dial, you can keep track of your cuts and ensure they line up nicely. Remember, in metalworking, precision is key. A little hiccup can turn a masterpiece into a paperweight! So, love your threading dial; it’s your best friend in the workshop!

| Benefit | Functionality |

|---|---|

| Increased Accuracy | Helps align cuts for perfect threads. |

| Ease of Use | Simple to read and operate, making tasks quicker. |

| Reduced Errors | Less chance of mistakes leads to better projects. |

Creating Custom Lathe CAD Files

Stepbystep process for designing threading dials using CAD software. Essential design considerations for optimal performance.Designing a threading dial with CAD software can be fun and rewarding! Start by sketching your idea on paper. Then, open your CAD program and create a new project. Measure your dial carefully; you want it to fit perfectly on your lathe. Don’t forget to consider user-friendliness and durability for optimal performance. Lastly, add some flair—maybe a quirky design that makes you smile each time you use it!

| Step | Description |

|---|---|

| 1 | Sketch your idea. |

| 2 | Create a new project in CAD. |

| 3 | Measure your dial for accuracy. |

| 4 | Focus on usability and strength. |

| 5 | Add creative touches. |

Finding and Downloading Lathe CAD Files

Reliable sources and online repositories for downloading existing CAD files. Tips for verifying CAD file quality and compatibility.Looking for lathe CAD files can feel like a treasure hunt, but don’t worry! Start by checking reliable websites like GrabCAD and Thingiverse. These treasure troves have many models ready for you to download. Want the best files? Always check reviews and comments from other users! A file with five-star ratings is usually a winner. And remember, compatibility is key. Don’t download a file if your lathe can’t handle it; that would be like trying to put a square peg in a round hole!

| Source | Notes |

|---|---|

| GrabCAD | Great user community and many designs. |

| Thingiverse | Simple interface and lots of free STL files. |

| CADBlocksFree | Offers free CAD files for various uses. |

Tips for Modifying Existing Lathe CAD Files

Techniques for customizing downloaded CAD files to meet specific needs. Common pitfalls to avoid when modifying CAD files.Modifying CAD files can feel like cooking without a recipe. Start by checking the file’s compatibility with your machine. Tweak measurements to fit your project while keeping dimensions proportional. For a smoother ride, avoid changing too many elements at once—it’s like juggling flaming torches! If you drop one, you might end up with a mess. Lastly, always save a backup before diving in. Trust me, future you will thank your past self!

| Tips | Common Pitfalls |

|---|---|

| Check compatibility | Changing too many elements |

| Tweak measurements | Not saving backups |

| Save backups | Ignoring the original file |

Remember, a good habit is to always preview your changes before finalizing them. Happy crafting!

Case Studies: Successful Projects Using Lathe CAD Files

Examples of projects that benefited from custom threading dial designs. Lessons learned from successful implementations.Many projects have thrived with customized threading dial designs. For instance, a workshop faced issues with accuracy while threading. By using tailored lathe CAD files, they created a precise dial. This improved their results significantly. Another example is a small business that increased production speed by 30% with the right design. Learning points include:

- Testing designs before production to avoid errors.

- Collaboration among team members leads to better designs.

- Continuous improvement is key to staying ahead.

Future Trends in Lathe Design and CAD Technology

Innovations in CAD technology impacting metal lathe capabilities. Predictions for the evolution of threading dials and their integration with CAD systems.New tools in CAD technology are changing how metal lathes work. These tools make designing parts easier and faster. Imagine being able to create a threading dial that fits perfectly every time. In the future, these dials will work closely with CAD systems, improving accuracy.

Here are some predictions:

- More user-friendly interfaces will appear.

- Cloud-based CAD will allow instant updates.

- Integration with AI could enhance designs.

These innovations can help makers create better products. They will save time and reduce errors.

How will CAD technology affect threading dials?

CAD technology will help design threading dials that are more accurate and easier to use.

Conclusion

In conclusion, metal lathe threading dials can greatly improve your machining projects. Using CAD files helps you design and customize these tools easily. You can enhance your skills and create better results. If you’re interested, explore more about CAD software and metal lathe techniques. Practice makes perfect, so start working on your projects today!FAQs

Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Threading Dials:Lathe CAD files are special drawings that show how to make parts for a lathe, which is a machine that shapes metal. You can use these files to help you create things accurately. Metal lathe threading dials help you measure and mark where to cut threads on metal pieces. These dials make it easier to get the measurements right. Using CAD files and threading dials together helps us create better metal parts!

Sure! Please ask your question, and I’ll be happy to help you with a short answer.

What Are The Key Design Features To Consider When Creating Cad Files For A Metal Lathe Threading Dial?When making CAD files for a metal lathe threading dial, you should include a clear scale. This helps everyone understand the size. Make sure the lines are smooth for easy reading. You should also plan for the holes where screws will go. Finally, check that everything lines up correctly so it fits the lathe well.

How Can Cad Software Be Utilized To Optimize The Manufacturing Process Of Threading Dials For Lathes?We can use Computer-Aided Design (CAD) software to make threading dials for lathes better and faster. First, CAD helps us design the dials on a computer. This lets us see how the dials will look before we make them. Next, we can change the design easily if something doesn’t fit right. Finally, using CAD makes it easier to plan how to build the dials, saving time and material.

Are There Specific File Formats That Are More Suitable For Sharing Lathe Cad Files For Threading Dials Among Machinists?Yes, there are specific file formats that work well for sharing lathe CAD files. We can use formats like DXF, STL, or DWG. These make it easy for machinists to open and use the files. Each format has its own benefits, so you can pick the one that fits best.

What Common Challenges Do Designers Face When Developing Cad Files For Threading Dials On Metal Lathes, And How Can They Be Overcome?Designers often face problems like making clear drawings and fitting parts together. If the drawings are messy, it’s hard to understand them. To fix this, we can use simple designs and double-check our work. It’s also important to measure carefully to ensure everything fits well. Working together with others can help us spot mistakes early.

How Can Modeling Enhance The Functionality And Accuracy Of Threading Dials In Metal Lathe Applications?Modeling helps us design better threading dials for metal lathes. By creating a digital version, we can see how it works before making it. This way, we can fix problems and make it more accurate. When threading dials are better, they help us make tighter and cleaner threads. This means the parts we create will fit together perfectly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe CAD files are special drawings that show how to make parts for a lathe, which is a machine that shapes metal. You can use these files to help you create things accurately. Metal lathe threading dials help you measure and mark where to cut threads on metal pieces. These dials make it easier to get the measurements right. Using CAD files and threading dials together helps us create better metal parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Key Design Features To Consider When Creating Cad Files For A Metal Lathe Threading Dial?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making CAD files for a metal lathe threading dial, you should include a clear scale. This helps everyone understand the size. Make sure the lines are smooth for easy reading. You should also plan for the holes where screws will go. Finally, check that everything lines up correctly so it fits the lathe well.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Optimize The Manufacturing Process Of Threading Dials For Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use Computer-Aided Design (CAD) software to make threading dials for lathes better and faster. First, CAD helps us design the dials on a computer. This lets us see how the dials will look before we make them. Next, we can change the design easily if something doesn’t fit right. Finally, using CAD makes it easier to plan how to build the dials, saving time and material.”}},{“@type”: “Question”,”name”: “Are There Specific File Formats That Are More Suitable For Sharing Lathe Cad Files For Threading Dials Among Machinists?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are specific file formats that work well for sharing lathe CAD files. We can use formats like DXF, STL, or DWG. These make it easy for machinists to open and use the files. Each format has its own benefits, so you can pick the one that fits best.”}},{“@type”: “Question”,”name”: “What Common Challenges Do Designers Face When Developing Cad Files For Threading Dials On Metal Lathes, And How Can They Be Overcome?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Designers often face problems like making clear drawings and fitting parts together. If the drawings are messy, it’s hard to understand them. To fix this, we can use simple designs and double-check our work. It’s also important to measure carefully to ensure everything fits well. Working together with others can help us spot mistakes early.”}},{“@type”: “Question”,”name”: “How Can Modeling Enhance The Functionality And Accuracy Of Threading Dials In Metal Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modeling helps us design better threading dials for metal lathes. By creating a digital version, we can see how it works before making it. This way, we can fix problems and make it more accurate. When threading dials are better, they help us make tighter and cleaner threads. This means the parts we create will fit together perfectly!”}}]}