Have you ever wondered how a metal lathe works? It’s a fascinating machine that shapes metal into precise forms. But did you know that one of its most important aspects is calibration?

Think about baking a cake. If your measurements are off, the cake won’t rise and taste great. The same goes for a lathe. Proper lathe calibration ensures that every cut is perfect. This process helps the lathe produce exactly what you design in CAD.

CAD, or computer-aided design, allows users to create detailed drawings and models. Imagine designing your own parts or tools from scratch! When you combine CAD with a well-calibrated metal lathe, you can turn ideas into reality.

In this article, we will explore the world of lathe calibration. You’ll learn why it matters and how to get it right. Let’s dive into this exciting journey of metalworking and design!

Lathe Calibration: Perfecting Metal Lathe Cad Design

Lathe Calibration Metal Lathe CAD Design

Lathe calibration is crucial for precision in metalworking. When using a metal lathe, proper calibration ensures accurate cuts and measurements. CAD design tools help visualize projects, leading to better planning and execution. Did you know that a tiny miscalibration can cause major issues in your final product? By mastering these skills, you create high-quality parts efficiently. Learning about lathe calibration and utilizing CAD design can significantly enhance your machining capabilities and project outcomes.Understanding Lathe Calibration

Definition and importance of lathe calibration. Key factors affecting calibration accuracy.Lathe calibration means checking and adjusting how a lathe machine works. It’s super important for getting the best results in metalworking. Proper calibration helps ensure precision and accuracy in designs. If a lathe isn’t calibrated, it can cause errors in parts. Key factors that affect calibration include:

- Wear and tear of parts

- Temperature changes

- Operator skill level

Taking care of these factors can improve machine performance and quality of work.

Why is lathe calibration important?

Calibration is vital as it prevents mistakes and increases efficiency, leading to better products.The Role of CAD Design in Lathe Calibration

How CAD design aids in the calibration process. Advantages of integrating CAD with metal lathe operations.CAD design plays a big part in calibrating metal lathes. It helps create precise models, making adjustments easier. By using CAD, engineers can quickly find and fix issues. It’s like having a magical toolbox that shows you where to tighten or loosen things! Plus, CAD can save time, making operations smoother. Think of it as a friendly robot that helps your lathe work like a charm.

| Advantages of CAD in Lathe Calibration | Description |

|---|---|

| Precision | CAD provides exact measurements for better calibrations. |

| Time-Saving | Fewer errors lead to faster production, making everyone happy! |

| Visualization | View designs in 3D helps to spot problems before they happen. |

Essential Tools and Equipment for Calibration

List of musthave tools for accurate calibration. Recommendations for reliable calibration equipment.Calibration is like fitting new shoes. You need the right tools to make everything comfortable and accurate. Here’s a nifty list of must-have tools for precision calibration:

| Tool | Description |

|---|---|

| Calipers | For measuring lengths with the accuracy of a hawk! |

| Dial Indicator | Checks the movement with a twitch of your finger. |

| Calibration Gage | Ensures your machine is as straight as a line drawn by a ruler. |

Reliable equipment makes your calibration as smooth as butter. Don’t skimp on tools! They can save time and sanity. Remember, without accurate calibration, your lathe could be wobbling more than a toddler learning to walk!

Step-by-Step Guide to Calibrating Your Metal Lathe

Detailed procedures for effective lathe calibration. Common mistakes to avoid during calibration.Calibrating your metal lathe is essential for precise work. Follow these steps for success:

- Check the leveling of the lathe.

- Measure spindle alignment with a dial gauge.

- Adjust the tailstock for straight cuts.

- Verify the speed settings with a tachometer.

Avoid these common mistakes:

- Skipping the leveling process.

- Neglecting to check all measurements.

- Forgetting to secure adjustments.

By following these tips, you’ll achieve accuracy every time you use your lathe!

What are the common mistakes during lathe calibration?

Common mistakes include skipping the leveling process, neglecting to measure properly, and not securing adjustments. Avoiding these errors helps ensure your lathe works well and produces quality results.

Maintaining Calibration Accuracy Over Time

Tips for ensuring longterm calibration accuracy. Importance of routine checks and adjustments.Keeping your metal lathe calibrated is very important. Small changes over time can affect how well your machine works. Here are some tips:

- Check your machine regularly.

- Clean it often to avoid dust buildup.

- Adjust settings when needed.

Routine checks help catch issues before they become big problems. Even a small change can impact your projects. Remember, a well-maintained lathe lasts longer and works better!

Why is regular calibration important?

Regular calibration keeps your lathe reliable and precise. It ensures the quality of your work and prevents costly mistakes. Think of it like tuning a musical instrument. If it’s out of tune, the music will sound wrong! Keep your lathe in tune to make perfect parts every time.

Case Studies: Successful Lathe Calibration Examples

Realworld examples of effective lathe calibration. Lessons learned and best practices from each case.Many shops have mastered lathe calibration, turning their challenges into victories. For instance, an aerospace company faced accurate cuts and got it right through a revamped calibration process. They learned to schedule regular checks, avoiding the “Oops, I did it again!” syndrome. Another automotive firm discovered using CAD design helped spot errors early. Their motto: “Measure twice, cut once!” These examples remind us that precision isn’t just about tools; it’s also about brains working behind them!

| Case Study | Issue | Solution | Lesson Learned |

|---|---|---|---|

| Aerospace Company | Accurate cuts | Revamped calibration | Regular checks are key |

| Automotive Firm | Spot errors | Using CAD design | Measure twice, cut once! |

Future Trends in Lathe Calibration and CAD Design

Innovations in lathe technology and calibration methods. The impact of automation and AI on calibration processes.New tools and methods are changing how we calibrate lathes. Innovations in machinery make calibration faster and easier. For example, machines now use advanced sensors that provide instant feedback. Automation and AI are also changing the game.

- AI can predict when a machine will need calibration.

- Automated systems reduce human error.

These changes help manufacturers boost efficiency and accuracy. Less downtime means more work gets done, making the future of lathe calibration exciting!

What is the role of automation in lathe calibration?

Automation helps machines to calibrate themselves. This reduces the need for human workers to do simple tasks. It also makes the process quicker and more precise.

Conclusion

In conclusion, lathe calibration is essential for accurate metalworking. Understanding CAD design helps you plan better projects. Both skills improve your work quality and efficiency. We encourage you to practice lathe calibration and explore CAD tools. Learning these skills can make your projects successful and enjoyable. Keep reading and experimenting to enhance your metalworking journey!FAQs

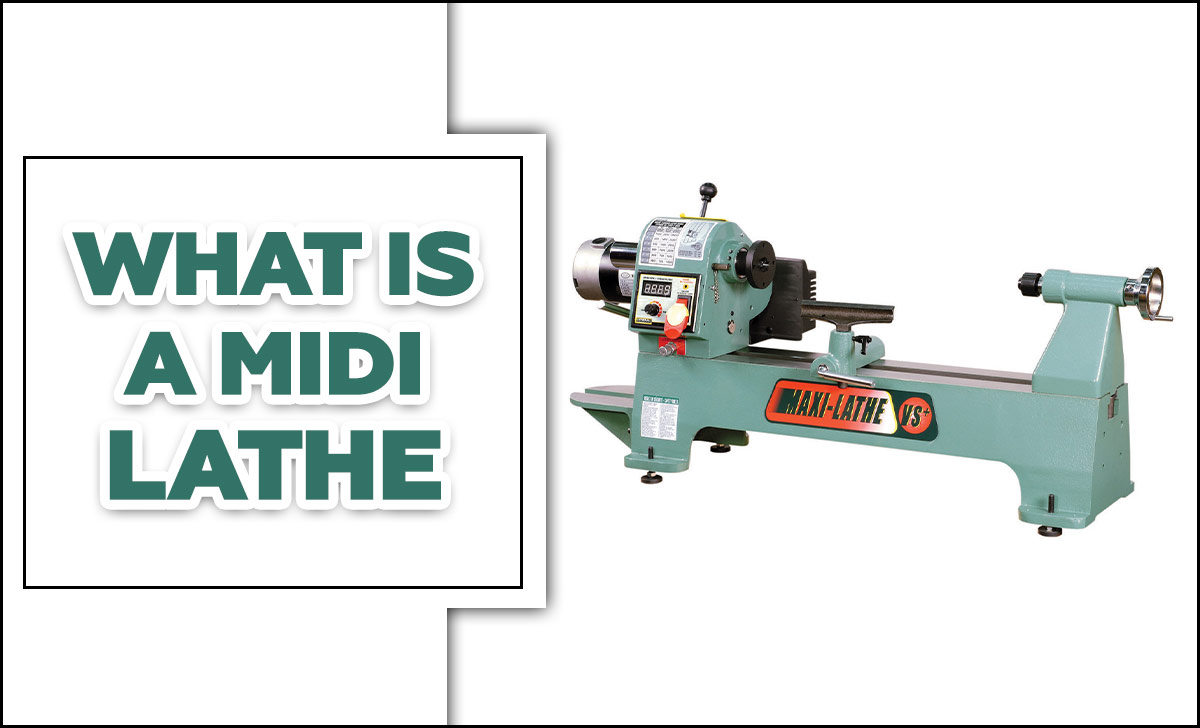

Sure! Here Are Five Related Questions On The Topic Of Lathe Calibration, Metal Lathe, And Cad Design:Sure! A metal lathe is a machine that shapes metal parts. To keep it working well, we need to calibrate it. This means we check and adjust it to make sure it cuts correctly. CAD stands for Computer-Aided Design. It helps us create designs on a computer before we make them in real life.

Sure! Please provide the question you would like me to answer.

What Are The Key Steps Involved In Calibrating A Metal Lathe To Ensure Precise Machining Operations?To calibrate a metal lathe, you start by ensuring it’s level on the floor. Next, check the alignment of the parts that spin. Then, measure the tools to make sure they are sharp and straight. After that, set the right speed for the material you are using. Finally, test the lathe by making a small piece to see if it works well.

How Can Cad Design Software Be Utilized To Optimize The Setup And Operation Of A Metal Lathe For Specific Projects?We can use CAD design software to plan our projects for a metal lathe. It helps us see what we want to make in 3D. You can check the size and shape of the pieces before starting. This way, we can change things if needed, saving time and materials. Using CAD makes our work easier and better!

What Common Errors Can Occur During The Calibration Process Of A Lathe, And How Can They Be Mitigated?When we calibrate a lathe, we might make a few mistakes. One common error is not measuring things correctly. To fix this, you can double-check your measurements and use a good ruler. Another mistake is setting the machine wrong. We can avoid this by following the instructions closely and asking for help if needed. Finally, dirt and dust can get in the way, so remember to keep the lathe clean!

In What Ways Can Modeling In Cad Contribute To Improving The Accuracy Of Parts Manufactured On A Metal Lathe?Modeling in CAD (Computer-Aided Design) helps us make better parts for a metal lathe. We can see our design in 3D before making it. This lets us find mistakes and fix them early. By planning carefully, we can make sure everything fits just right. Overall, CAD helps us create parts that are more accurate and work better!

How Do Different Materials Affect The Calibration Process Of A Metal Lathe, And What Considerations Should Be Taken Into Account During Design In Cad?Materials affect how we set up a metal lathe. Some materials are stronger and offer more stability. If we use soft materials, they can bend or change shape easily. In CAD (Computer-Aided Design), we must pick the right materials for our designs. Strong materials help make sure everything works well together.