Have you ever wondered how machines create such precise parts? A metal lathe plays a huge role in that process. But what happens when your lathe doesn’t work as well as it should? Calibration is key to making sure it runs smoothly. Without proper lathe calibration, you’re likely to face big problems in your projects.

Many people are now turning to CNC retrofit for their older lathes. This process upgrades a traditional lathe with modern technology. Imagine turning that old machine into something that works like new! Sounds exciting, right?

This article will explore how to calibrate your lathe and the benefits of a CNC retrofit. Get ready to discover tips and tricks that can help you master your metal lathe. Let’s dive into the world of precision engineering and innovation!

Lathe Calibration: Metal Lathe Cnc Retrofit Guide

Lathe Calibration: Improving Your Metal Lathe with CNC Retrofit

Lathe calibration is important for achieving accurate results in machining. A well-calibrated metal lathe helps to produce precise parts every time. With a CNC retrofit, you can upgrade traditional lathes for better performance. This means more control and efficiency in your projects. Did you know a simple adjustment can make a big difference? Proper calibration ensures that your lathe works as it should, saving you time and materials while enhancing your skills.Benefits of Proper Lathe Calibration

Enhanced precision and consistency in machining operations. Reduction of waste and rework costs in manufacturing.Proper lathe calibration can make a world of difference in machining. With accurate settings, parts come out just right. Imagine trying to make a pizza with wonky crust! You’d end up with a lot of dough on the floor and not much on the plate. Calibration minimizes waste and cuts down on rework costs, saving everyone time and money. Simply put, it’s like having a superhero for your lathe—fighting errors and keeping production smooth!

| Benefit | Description |

|---|---|

| Enhanced Precision | Parts fit perfectly, like puzzle pieces! |

| Less Waste | Fewer mistakes mean more cash in your pocket! |

Key Components of a Lathe Calibration Process

Detailed examination of the mechanical and electronic components involved. Importance of aligning the headstock, tailstock, and bed for accuracy.Lathe calibration requires careful attention to several parts. Main components include the headstock, tailstock, and bed. Aligning these parts is essential for accuracy. If they aren’t lined up correctly, it might ruin your project. It’s like trying to build a straight wall with wonky bricks! Here’s a quick look at the components:

- Headstock: Where the motor and spindle are located.

- Tailstock: Helps support the workpiece and provides adjustments.

- Bed: The base that keeps everything stable and straight.

What does a lathe do?

A lathe shapes materials by rotating them against cutting tools.Tools Required for Lathe Calibration

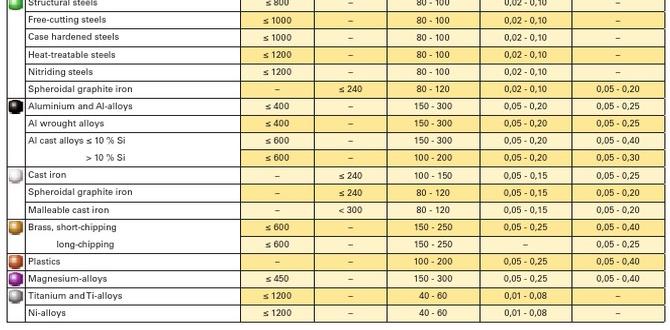

List of essential calibration tools (e.g., dial indicators, gauges). Explanation of how to use each tool effectively for calibration.To ensure your lathe works well, you need some essential tools for calibration. Here’s a list:

- Dial Indicator: Use this tool to measure small distances. Place it on the lathe and adjust until it shows the correct reading.

- Gauges: These help measure things like depth and diameter. Check these sizes against your lathe specs.

- Tape Measure: Useful for larger distances. Make sure to check your lathe setup.

Using these tools properly leads to a well-calibrated machine. Your projects will turn out much better!

What tools do I need for lathe calibration?

You will need a dial indicator, gauges, and a tape measure for proper calibration. These tools help you check measurements accurately.

Step-by-Step Lathe Calibration Procedures

Detailed instructions for calibrating the lathe’s axis alignment. Methods for adjusting backlash and ensuring spindle accuracy.Calibrating a lathe might sound like wizardry, but it’s quite simple! First, check the axis alignment. Use a dial indicator on the carriage and slide it along the bed. Adjust the leveling feet until everything is nice and flat, like a pancake. Next, tackle backlash. Tighten the gibs and adjust the nuts to minimize the play. Finally, ensure spindle accuracy by measuring with a test bar. Don’t worry; precision can be learned faster than your favorite dance move!

| Procedure | Steps |

|---|---|

| Axis Alignment | Use a dial indicator on the carriage. Slide it along the bed. |

| Adjust Backlash | Tighten gibs. Adjust nuts to reduce play. |

| Spindle Accuracy | Measure with a test bar for precise adjustments. |

Common Issues in Lathe Calibration and Their Solutions

Identification of frequent calibration problems and their causes. Practical solutions to rectify common calibration errors.Calibration problems can feel like catching greased pigs – tricky and messy! One common issue is slippage. This happens if your lathe isn’t tight enough, causing errors in measurement. Another is wear and tear. Old parts can turn into rebels, messing with accuracy. To fix slippage, check your machine’s bolts. For wear and tear, it’s time for a part upgrade. Remember, a well-calibrated lathe is a happy lathe!

| Issue | Cause | Solution |

|---|---|---|

| Slippage | Loose components | Tighten all bolts |

| Wear and Tear | Old or broken parts | Upgrade parts |

When to Consider CNC Retrofit for Your Lathe

Signs indicating the need for a CNC retrofit in existing lathe setups. Benefits of upgrading to CNC controls for better precision and efficiency.Look out for signs that your lathe needs an upgrade. Is your machine producing inconsistent results? Are you frustrated with its speed? If yes, it’s time to think about a CNC retrofit. Upgrading to CNC controls offers many perks. You can achieve more precision in cuts and improve efficiency of operations.

- Increased accuracy in measurements

- Faster production speeds

- Less waste of materials

- Improved control over designs

Evolving technology helps lathe users stay competitive. With a CNC retrofit, you can unlock your lathe’s full potential.

What are the signs that you need a CNC retrofit?

Common signs include inconsistent performance, frequent errors, and slow production rates. If your lathe feels outdated, a retrofit can transform it for better results.

Best Practices for Ongoing Lathe Maintenance and Calibration

Recommended schedules for routine calibration checks. Tips for maintaining optimal lathe performance over time.Keeping your lathe in top shape is like brushing your teeth: do it often, or things get messy! For routine calibration, check your lathe every 3-6 months. This helps catch problems early, saving you time and money. Here are some tips to keep your lathe singing: always clean it after use and use the right tools. Regular oiling can also make things run smoothly. Just like a chocolate cake, it’s all about the right ingredients!

| Routine Check Schedule | Maintenance Tip |

|---|---|

| Every Month | Dust and clean the machine. |

| Every 3 Months | Calibrate measurements. |

| Every 6 Months | Inspect belts and parts. |

Stay proactive! Keeping up with these practices will help your lathe perform like a pro. And remember, a well-maintained lathe is a happy lathe!

Conclusion

In summary, lathe calibration is essential for accurate metalwork. Retrofitting a CNC lathe improves efficiency and precision. We can enhance our skills by learning proper calibration methods. Consider trying a retrofit project for hands-on experience. Explore more resources to deepen your understanding and boost your confidence in using metal lathes. Let’s keep learning and creating great things together!FAQs

What Are The Key Steps Involved In Calibrating A Metal Lathe For Optimal Precision In Cnc Retrofitting?To calibrate a metal lathe for CNC retrofitting, follow these steps. First, clean the lathe well. This helps you see any problems more easily. Next, make sure all parts are tight and not loose. Then, check the alignment to ensure everything is straight. Finally, test it out with a small piece to see if it cuts correctly.

How Does The Accuracy Of A Cnc Retrofitted Lathe Compare To That Of A Factory-Built Cnc Lathe?A CNC retrofitted lathe is an old lathe changed to work like a new one. It can be accurate, but not always as good as a factory-built CNC lathe. Factory-built lathes are specially made for precision and usually do a better job. So, if you want the best accuracy, a factory-built lathe is a safer choice. However, a retrofitted lathe can still work well with the right upgrades.

What Tools And Equipment Are Necessary For The Calibration Process Of A Metal Lathe During A Cnc Retrofit?To calibrate a metal lathe during a CNC retrofit, you need a few important tools. First, you should have a digital caliper to measure parts accurately. You will also need a dial indicator to check how well the lathe moves. A level will help you make sure the lathe sits flat. Lastly, you might use a software program to help with the settings.

What Common Challenges Do Users Face When Calibrating A Metal Lathe After A Cnc Retrofit, And How Can They Be Addressed?When you change a metal lathe to work with a CNC, or Computer Numerical Control, system, you might face a few problems. One challenge is ensuring the machine moves to the right spots. You can solve this by carefully checking each part and watching how it cuts. Another issue is getting the speed right. To fix this, you can adjust the settings and test the machine multiple times. Regular checks help you catch and fix any mistakes quickly.

How Can Regular Calibration And Maintenance Of A Cnc Retrofitted Lathe Enhance Machining Performance And Prolong The Equipment’S Lifespan?Regularly checking and fixing a CNC (Computer Numerical Control) lathe helps it work better. When we keep it clean and adjusted, it cuts materials more smoothly. This means fewer mistakes, which saves time and materials. Plus, taking care of the machine can help it last longer, so we don’t have to buy a new one too soon. Overall, good care makes our work easier and saves money!