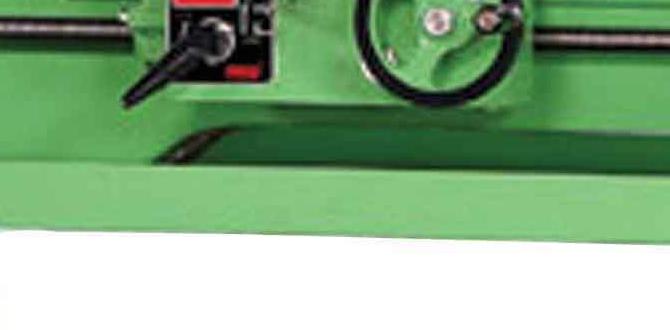

Have you ever wondered how to get the perfect cut on a metal lathe? The secret often lies in lathe calibration, especially with the metal lathe pulley. Proper calibration can make a huge difference in your work. Imagine watching your projects turn out just the way you planned!

Calibrating your lathe can seem tricky. But it’s important for precision and accuracy. Did you know that even small mistakes in calibration can lead to big problems in your final project? A misaligned pulley can create errors that ripple through your work.

In this article, we’ll explore how to calibrate your lathe effectively. We’ll also look at how the metal lathe pulley plays a vital role in this process. So, get ready to learn some easy and helpful tips that can improve your skills! You’ll be amazed at what you can achieve with the right techniques.

Lathe Calibration: Perfecting Metal Lathe Pulley Settings

Understanding Lathe Calibration: Metal Lathe Pulley

Calibration of a metal lathe is essential for precision. A properly calibrated lathe ensures that the pulley system operates smoothly. Did you know that even tiny misalignments can lead to major mistakes in your projects? Regular checks can improve accuracy and extend the life of your equipment. By understanding how to calibrate, you can create better results and avoid frustration. Learning these simple steps can turn you into a more skilled machinist. Why not give it a try?Components of Metal Lathe Pulleys

Detailed description of a metal lathe pulley and its function. Different types of metal lathe pulleys found in machines.Pulleys are crucial parts of metal lathes. They help control the speed and direction of the machine. A metal lathe pulley connects the motor to the spindle. This connection gives power to cut and shape materials. Different types of pulleys exist, each serving a unique purpose. Some common types include:

- V-Belt Pulleys

- Flat Pulleys

- Adjustable Pulleys

Each type helps the lathe function smoothly. Understanding these components makes it easier to operate the machine effectively.

What is the role of a metal lathe pulley?

The role of a metal lathe pulley is to transfer power from the motor to the lathe. This allows the lathe to spin materials for cutting. This process is essential for creating parts of different shapes and sizes.

Tools and Equipment Needed for Calibration

List of essential tools for calibrating metal lathe pulleys. Safety equipment and measures to consider during calibration.Calibrating metal lathe pulleys requires some key tools. You will need a calibrator, feeler gauges, and a level. A wrench set helps too. You can’t forget safety gear! Always wear safety glasses and gloves. Protect your ears as well; they deserve a break from the noise. Here’s a quick rundown of what you need:

| Tool/Equipment | Purpose |

|---|---|

| Calibrator | Checks precision |

| Feeler Gauges | Measures gaps |

| Level | Ensures balance |

| Wrenches | Tightens bolts |

| Safety Gear | Protects you |

With these tools, you’re all set to make your lathe as precise as a cat on a hot tin roof. Remember, safety first – because no one wants to be the punchline in a “what happened to my fingers” joke!

Step-by-Step Calibration Process

Detailed steps for calibrating a metal lathe pulley. Common challenges faced during calibration and solutions.Calibrating a metal lathe pulley is a key task to ensure accuracy. Start by loosening the pulley set screws. Next, align the pulley with the spindle. Use a level to check for balance. Tighten the screws after adjustments. Common challenges include misalignment and slipping belts. To solve these, double-check alignment and ensure the belt is tight.

What are the common issues during lathe calibration?

Common issues include alignment problems and slipping belts. Misalignment can lead to uneven cuts, while loose belts can cause slowing. Regular checks can prevent these issues.

Tips to fix these issues:

- Check everything is level.

- Tighten all screws and belts carefully.

- Use a caliper for precise measurements.

Testing Accuracy After Calibration

Methods for testing the accuracy of the lathe after calibration. Importance of regular testing and maintenance for optimal performance.After calibration, it’s important to test the lathe’s accuracy. You want to ensure that it cuts correctly. Here are some methods:

- Measure a test piece for size and shape.

- Check for consistent cuts at different speeds.

- Use calipers to verify dimensions.

Regular testing keeps your lathe working well. It prevents costly mistakes. Maintenance ensures that everything runs smoothly for a long time.

Why is testing important for lathe performance?

Testing helps catch problems early. It keeps your lathe in top shape and extends its life.

Common Issues and Troubleshooting

Identification of common calibration issues in metal lathe pulleys. Troubleshooting tips and solutions for calibration problems.Metal lathe pulleys can face calibration issues that affect performance. Common signs include vibrations, noisy operations, or uneven cuts. These problems can arise from misalignment or wear over time. Thankfully, fixing these issues is often straightforward.

- Check for any worn-out components.

- Ensure that pulleys are aligned properly.

- Adjust tension as needed.

Regular maintenance can prevent many of these issues. Always consult the user manual for guidance and keep your lathe clean and lubricated.

What are some common calibration problems with metal lathe pulleys?

Common problems include misalignment, excessive wear, and improper tension on belts. These issues can lead to poor cutting performance and safety risks. Addressing them early can save time and effort.

How can I troubleshoot these calibration problems?

- Inspect for wear and tear regularly.

- Align pulleys correctly to ensure smooth operation.

- Tighten or adjust belts to the recommended tension.

Best Practices for Lathe Maintenance

Routine maintenance tips for ensuring longevity and precision. Recommended schedules and checklists for effective lathe maintenance.Keeping your lathe happy is like feeding a pet; it needs love and care! Regular checks are key to ensuring your lathe stays precise and works well. Schedule maintenance every month to clean the parts and check for wear. It’s like spring cleaning, but for your machine! You can follow this simple checklist:

| Maintenance Task | Frequency |

|---|---|

| Clean the lathe | Every week |

| Grease the pulley | Monthly |

| Check belts and gears | Every two months |

| Inspect for rust | Every six months |

This routine helps prevent issues and extends the lathe’s lifespan. Remember, a well-maintained lathe will be as reliable as your favorite superhero—always ready for action!

Resources for Further Learning

Suggested reading materials and online courses. Communities and forums for ongoing support and knowledge sharing.Learning is exciting! There are many resources that can help you understand lathe calibration better. Here are some suggestions:

- Books on metalworking and machinery.

- Online courses about lathe operation and maintenance.

- Communities and forums where you can ask questions and share ideas.

- Video tutorials for hands-on learning.

These resources will guide you. You can connect with others who share your interests. Don’t hesitate to explore these options for more knowledge!

What are some good online resources for learning about metal lathes?

Many websites offer free and paid resources. Some popular ones include Udemy and Coursera for courses, and Reddit and Facebook groups for community support.

Conclusion

In summary, lathe calibration is essential for accurate machining. Checking your metal lathe pulley ensures smooth operation and better results. Maintain your equipment regularly to avoid issues and improve performance. Remember, a well-calibrated lathe helps you create high-quality workpieces. Consider reading more about lathe maintenance to enhance your skills and keep your projects on track!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Calibration, Specifically Focusing On Metal Lathe Pulleys:Sure! I can help with that. Here are some questions about lathe calibration and metal lathe pulleys: 1. What is a lathe? A lathe is a machine that helps shape metal or wood. It spins the material while tools cut or smooth it. 2. Why is calibration important? Calibration makes sure the lathe is working correctly. It helps you create parts that fit perfectly. 3. What are pulleys used for in lathes? Pulleys help transfer energy from the motor to the lathe. They change how fast the lathe spins. 4. How do you check if pulleys are working well? You can look for wear or looseness in the belts on the pulleys. Make sure everything is tight and not damaged. 5. What should you do if the lathe isn’t spinning right? If the lathe doesn’t spin properly, check the pulleys and belts first. You might need to adjust or replace them.

Sure! Just ask your question, and I’ll provide a short answer for you.

What Are The Key Steps Involved In Calibrating The Pulleys Of A Metal Lathe For Accurate Performance?To calibrate the pulleys of a metal lathe, follow these steps. First, you need to check if the lathe is level. Use a level tool to help with this. Next, loosen the pulley screws but don’t take them off. Then, adjust the pulleys so they line up correctly. Finally, tighten the screws back up and test the lathe to make sure it works well.

How Does Pulley Alignment Affect The Overall Accuracy And Precision Of Machining On A Metal Lathe?Pulley alignment is important when using a metal lathe. If the pulleys are not lined up correctly, the machine can vibrate. This makes it hard to cut metal accurately. When the machine cuts unevenly, it can replace the part you are making. Good alignment helps us make better, more precise parts.

What Tools And Equipment Are Necessary For Properly Calibrating And Adjusting Lathe Pulleys?To calibrate and adjust lathe pulleys, you need a few tools. First, get a tape measure to check distances. A wrench helps you tighten or loosen bolts. You also need a level to make sure everything is even. Finally, a screwdriver can help with small adjustments.

How Can Wear And Tear On Lathe Pulleys Impact The Calibration Process And The Quality Of The Finished Product?When lathe pulleys get worn out, they can’t work properly. This means the machine might not spin at the right speed. If that happens, the parts we make can be not shaped correctly. So, we need to check and fix the pulleys to keep everything working well and make better products.

What Common Issues Might Arise During Metal Lathe Pulley Calibration, And How Can They Be Effectively Resolved?When we calibrate a metal lathe pulley, we might face a few common problems. Sometimes the pulley can be too loose or too tight. If it is too loose, you can add washers to tighten it up. If it’s too tight, you can remove washers or adjust its position. We can also check if the lathe is level to avoid other issues.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Calibration, Specifically Focusing On Metal Lathe Pulleys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help with that. Here are some questions about lathe calibration and metal lathe pulleys: 1. What is a lathe? A lathe is a machine that helps shape metal or wood. It spins the material while tools cut or smooth it. 2. Why is calibration important? Calibration makes sure the lathe is working correctly. It helps you create parts that fit perfectly. 3. What are pulleys used for in lathes? Pulleys help transfer energy from the motor to the lathe. They change how fast the lathe spins. 4. How do you check if pulleys are working well? You can look for wear or looseness in the belts on the pulleys. Make sure everything is tight and not damaged. 5. What should you do if the lathe isn’t spinning right? If the lathe doesn’t spin properly, check the pulleys and belts first. You might need to adjust or replace them.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll provide a short answer for you.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Calibrating The Pulleys Of A Metal Lathe For Accurate Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the pulleys of a metal lathe, follow these steps. First, you need to check if the lathe is level. Use a level tool to help with this. Next, loosen the pulley screws but don’t take them off. Then, adjust the pulleys so they line up correctly. Finally, tighten the screws back up and test the lathe to make sure it works well.”}},{“@type”: “Question”,”name”: “How Does Pulley Alignment Affect The Overall Accuracy And Precision Of Machining On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Pulley alignment is important when using a metal lathe. If the pulleys are not lined up correctly, the machine can vibrate. This makes it hard to cut metal accurately. When the machine cuts unevenly, it can replace the part you are making. Good alignment helps us make better, more precise parts.”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Necessary For Properly Calibrating And Adjusting Lathe Pulleys?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate and adjust lathe pulleys, you need a few tools. First, get a tape measure to check distances. A wrench helps you tighten or loosen bolts. You also need a level to make sure everything is even. Finally, a screwdriver can help with small adjustments.”}},{“@type”: “Question”,”name”: “How Can Wear And Tear On Lathe Pulleys Impact The Calibration Process And The Quality Of The Finished Product?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When lathe pulleys get worn out, they can’t work properly. This means the machine might not spin at the right speed. If that happens, the parts we make can be not shaped correctly. So, we need to check and fix the pulleys to keep everything working well and make better products.”}},{“@type”: “Question”,”name”: “What Common Issues Might Arise During Metal Lathe Pulley Calibration, And How Can They Be Effectively Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we calibrate a metal lathe pulley, we might face a few common problems. Sometimes the pulley can be too loose or too tight. If it is too loose, you can add washers to tighten it up. If it’s too tight, you can remove washers or adjust its position. We can also check if the lathe is level to avoid other issues.”}}]}