Have you ever wondered how precise machines keep their performance? Imagine trying to cut metal with a tool that isn’t calibrated correctly. It might end up being a messy job!

When you think of a metal lathe, picture a powerful machine spinning away. But did you know that lathe calibration is crucial? If it’s not calibrated, your projects may suffer. That’s where understanding torque comes in. Torque affects the cutting pressure, helping you achieve better results.

Here’s a fun fact: many skilled machinists believe calibration is the secret sauce of quality work. Regular checks can improve accuracy and extend your lathe’s life. Isn’t it amazing how a little attention can make a big difference?

In this article, we will explore why lathe calibration matters and how to measure torque effectively. Ready to dive in? Let’s unlock the secrets of the metal lathe together!

Lathe Calibration: Metal Lathe Torque Explained In Detail

Understanding Lathe Calibration: Metal Lathe Torque

Lathe calibration is essential for metalworking accuracy. Proper calibration ensures that your lathe operates effectively and safely. Did you know that incorrect torque can lead to poor cut quality? Understanding the right torque settings helps improve performance and tool life. Regular checks prevent costly errors. By familiarizing yourself with calibration techniques, you can enhance your projects. Isn’t it amazing how a little adjustment can make a big difference in your work?Torque in Metal Lathes

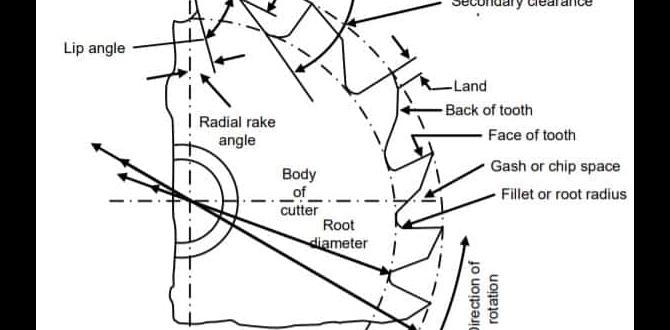

Explanation of torque and its relevance in lathe operations.. The relationship between torque and precision in machining..In machining, torque is the turning force applied to the lathe. It plays an essential role in how well a machine works. A lathe uses torque to spin materials. This spinning helps shape the metal accurately. High torque allows for precise cuts. If torque is low, it can lead to errors in shaping. Understanding torque helps improve results in metalwork. Proper calibration ensures the lathe operates smoothly, leading to better projects.

What is the relationship between torque and precision in machining?

Torque strongly influences precision in machining. High torque allows for accurate cuts, while low torque may cause mistakes.

Steps for Effective Lathe Calibration

Detailed procedures for calibrating torque settings on metal lathes.. Recommended frequency and conditions for calibration checks..Calibrating your metal lathe can be a breeze if you follow these easy steps! First, check the torque settings using a reliable torque wrench. This ensures everything hugs tight but not too tight—like your favorite pair of jeans after the holidays!

Next, it’s best to perform these calibrations every few months or after heavy use. Regular checks keep your lathe running smooth. Don’t forget to do it in a clean environment to avoid dust bunnies interfering.

| Task | Frequency |

|---|---|

| Torque Settings Check | Every 3 months |

| Thorough Calibration | After heavy use |

So, keep your lathe happy and healthy with these tips, and you’ll be turning metal like a pro!

Common Calibration Issues and Solutions

Identification of frequent calibration problems encountered with metal lathes.. Practical solutions and troubleshooting tips for calibration issues..Many people face problems with metal lathe calibration. These issues can lead to faulty work. Common problems include:

- Incorrect torque settings

- Misalignment of the spindle

- Wear on the machine parts

To fix these, check settings regularly. Always align spindle correctly. Replace worn parts to keep the lathe smooth. These simple steps can make a big difference.

What are common metal lathe calibration issues?

Common issues include torque problems, spindle misalignment, and worn parts.

The Benefits of Regular Lathe Calibration

How regular calibration improves machining accuracy and efficiency.. Costsaving advantages of maintaining torque accuracy in production..Keeping your lathe calibrated is like tuning your favorite guitar. It makes everything sound better! Regular calibration greatly boosts machining accuracy. With each spin, your lathe becomes more reliable, improving efficiency and saving time. Think of it this way: a well-calibrated lathe works smarter, not harder. This means fewer mistakes and less waste. In fact, companies can save up to 20% on production costs by maintaining torque accuracy! Your wallet will thank you!

| Benefit | Effect |

|---|---|

| Improved Accuracy | Fewer mistakes and better results |

| Increased Efficiency | Faster production times |

| Cost Savings | Lower production costs! |

Advanced Techniques in Lathe Calibration

Discussion on modern technologies and methods for enhanced calibration.. The role of software in monitoring and managing calibration processes..Modern lathe calibration uses exciting technologies for better results. Advanced methods include laser systems and digital sensors. These tools make calibration more precise and faster. Software plays a big role too. It helps track and manage the whole process smoothly. With software, operators can quickly spot issues and fix them. This saves time and money. Think about it—what if you could calibrate your lathe while sipping your morning coffee? That’s the power of new technology!

How does software help in lathe calibration?

Software helps by monitoring the calibration process and ensuring everything is working correctly. It collects data and alerts users when something is wrong.

- Tracks calibration details

- Identifies problems quickly

- Improves overall efficiency

Case Studies on Lathe Calibration Success

Realworld examples of businesses improving performance through effective calibration.. Lessons learned and best practices derived from these case studies..Many businesses have found success through proper lathe calibration. One company improved its production time by 20% after adjusting their metal lathe torque. Another reduced waste by 15% through better calibration practices. These results show how important calibration is for performance. Here are some lessons learned:

- Regular checks keep machines accurate.

- Training staff on calibration boosts confidence.

- Documenting results helps track improvements.

With these steps, companies can thrive and reduce errors. Calibration truly makes a difference!

How does lathe calibration improve business performance?

Calibrating a lathe improves accuracy, boosts efficiency, and cuts costs. Clear records of adjustments lead to better decisions.

Conclusion

In summary, calibrating your metal lathe is crucial for accuracy. Proper torque settings ensure precision in your projects. Check your machine regularly to maintain quality work. If you want to learn more, explore tutorials or manuals about lathe calibration. Understanding this process will make you a better machinist. Start applying these tips to improve your skills today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Calibration, Specifically Focusing On Metal Lathe Torque:Sure! To keep a metal lathe running well, we need to check its torque. Torque is the force that helps turn things. We twist bolts to make sure they are strong. Regular checks help us avoid problems later. It’s important for safe and smooth work.

Sure! Please share the question you’d like me to answer.

What Methods Are Commonly Used To Calibrate The Torque Settings On A Metal Lathe?To calibrate the torque settings on a metal lathe, we can use a few methods. First, we can use a torque wrench. This tool helps us measure how much turning power we’re using. Next, we can check the lathe’s manual for the correct settings. Lastly, we might adjust the settings until the metal cuts smoothly.

How Does Improper Torque Calibration Affect The Precision And Accuracy Of Machining Operations On A Lathe?Improper torque calibration can mess up how tight the parts are on a lathe. If things are too loose, they might move around, making our cuts not straight. If they’re too tight, we can break pieces or ruin our work. This means our finished item won’t fit well and might not look good. We want everything to be just right for the best results!

What Tools And Equipment Are Essential For Measuring Torque When Calibrating A Metal Lathe?To measure torque on a metal lathe, you need a torque wrench. This tool helps you check how tight something is. You also need a calibration weight to test the lathe’s settings. A stiff tape measure can help you find exact spots to check. Finally, a notebook is great for writing down your measurements.

How Often Should A Metal Lathe Be Recalibrated For Torque To Ensure Consistent Performance And Safety?You should check and recalibrate a metal lathe every six months. This helps keep it working safely and correctly. If you notice any problems or odd sounds, check it right away. Regular checks help you avoid accidents and make better parts.

What Are The Consequences Of Exceeding The Recommended Torque Limits On A Metal Lathe During Machining Processes?If you use too much force on a metal lathe, bad things can happen. The tools might break or wear out quickly. This can damage the metal you’re working on too. It can also make it harder to get a smooth finish. We should always follow the rules to keep our work safe and clean.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Calibration, Specifically Focusing On Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! To keep a metal lathe running well, we need to check its torque. Torque is the force that helps turn things. We twist bolts to make sure they are strong. Regular checks help us avoid problems later. It’s important for safe and smooth work.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Methods Are Commonly Used To Calibrate The Torque Settings On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the torque settings on a metal lathe, we can use a few methods. First, we can use a torque wrench. This tool helps us measure how much turning power we’re using. Next, we can check the lathe’s manual for the correct settings. Lastly, we might adjust the settings until the metal cuts smoothly.”}},{“@type”: “Question”,”name”: “How Does Improper Torque Calibration Affect The Precision And Accuracy Of Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper torque calibration can mess up how tight the parts are on a lathe. If things are too loose, they might move around, making our cuts not straight. If they’re too tight, we can break pieces or ruin our work. This means our finished item won’t fit well and might not look good. We want everything to be just right for the best results!”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Essential For Measuring Torque When Calibrating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure torque on a metal lathe, you need a torque wrench. This tool helps you check how tight something is. You also need a calibration weight to test the lathe’s settings. A stiff tape measure can help you find exact spots to check. Finally, a notebook is great for writing down your measurements.”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Be Recalibrated For Torque To Ensure Consistent Performance And Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check and recalibrate a metal lathe every six months. This helps keep it working safely and correctly. If you notice any problems or odd sounds, check it right away. Regular checks help you avoid accidents and make better parts.”}},{“@type”: “Question”,”name”: “What Are The Consequences Of Exceeding The Recommended Torque Limits On A Metal Lathe During Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you use too much force on a metal lathe, bad things can happen. The tools might break or wear out quickly. This can damage the metal you’re working on too. It can also make it harder to get a smooth finish. We should always follow the rules to keep our work safe and clean.”}}]}