Have you ever noticed how important precision is in machining? Lathe machines are powerful tools for shaping metal and wood. But one common problem makes things tricky: chip deflection. This issue can ruin your work and waste precious materials. Imagine carving out a perfect piece, only to find the chips bounce around and mess everything up. Frustrating, right?

Did you know that chip deflection can also affect the quality of your final product? When chips do not clear properly, they can scratch or mar the surface. This problem can make it hard to create that sharp edge or smooth finish you want. Understanding lathe chip deflection issues can help you take control of your machining process. So let’s dive in!

Understanding Lathe Chip Deflection Issues In Machining

Lathe Chip Deflection Issues

Lathe chip deflection can lead to quality problems in your workpiece. It’s when the chips produced during machining don’t flow smoothly. This can cause damage or imperfections. Did you know improper tool angles and speeds can worsen this? By adjusting these settings, you can reduce deflection and improve the final product. Effective chip management not only enhances quality but also increases tool life. Want smoother operations? Pay attention to lathe chip deflection!What is Lathe Chip Deflection?

Definition of lathe chip deflection. Importance of understanding chip behavior in machining processes.Lathe chip deflection happens when the chips, those tiny metal pieces, take a different path than expected during machining. Imagine trying to throw a frisbee straight, but it veers off like a confused squirrel! Understanding this behavior is important because it can affect the quality of your work. If the chips go wild, they can mess up the finish and even harm the machine. So, keeping an eye on chip behavior helps you make better parts and saves you from extra headaches!

| Key Point | Explanation |

|---|---|

| Definition | Chip deflection is how chips stray from their intended path. |

| Importance | Understanding behavior leads to better manufacturing and reduces mistakes. |

Common Causes of Chip Deflection

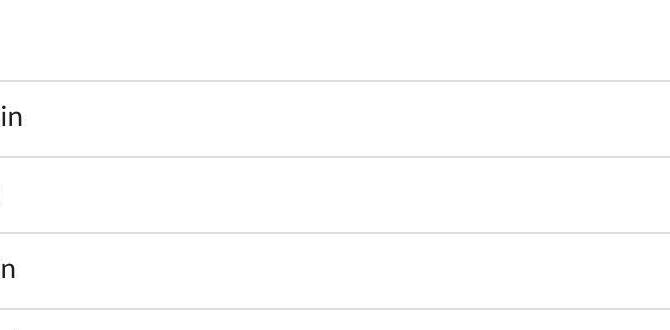

Tool geometry and its impact on chip formation. Material properties affecting chip behavior.Chip deflection can happen for a few reasons. First, the tool’s shape or geometry affects how it cuts. If the tool is dull or too sharp, it can create more chips. Second, the material being cut plays a big role too. Hard metals make tougher chips. Soft metals can bend easily. These factors together can lead to bad chip behavior. Let’s look at some key points:

- Sharp tools cut smoothly.

- Dull tools create more chips.

- Hard materials resist bending.

- Soft materials can easily change shape.

What affects chip formation in lathe work?

Tool geometry and material properties together shape how chips form. A well-designed tool and the right material improve chip quality. This also helps reduce deflection issues.

Effects of Chip Deflection on Machining Quality

Influence on surface finish and accuracy. Impact on tool life and wear rates.Chip deflection can harm machining quality. It affects how smooth the surface is and how close the part is to the right size. If the chips bounce around too much, the finish may become rough. This can make parts look bad and not fit well.

Also, when chips deflect, tools wear out faster. That’s because the tool gets uneven pressure. This shortens the tool’s life, making it need replacements sooner.

Think about these points:

- **Surface Finish:** Rough surfaces lead to poor quality.

- **Accuracy:** Deflection causes parts to miss the exact size.

- **Tool Life:** Less time before tools need replacing.

- **Wear Rates:** More wear means more breakage.

What are the effects of chip deflection on machining?

Chip deflection affects surface quality and tool life. A rough surface may lead to more errors. Also, tools that wear out quickly can increase costs.

Measuring and Identifying Chip Deflection Issues

Techniques for monitoring chip flow and deflection. Importance of visual observations during machining.Keeping an eye on chip flow and deflection is vital for smooth machining. Use visual observations to spot issues early. By watching how chips behave, you can detect problems before they turn into disasters. Consider using tools like chip detectors or monitoring systems to gather data. This will help you analyze patterns. Don’t underestimate the power of a keen eye! Remember, in machining, good chips are happy chips!

| Technique | Description |

|---|---|

| Visual Inspection | Look for unusual chip shapes or sizes. |

| Chip Monitoring Systems | Use devices that track chip flow in real time. |

| Data Analysis | Evaluate collected data for patterns. |

Strategies for Reducing Chip Deflection

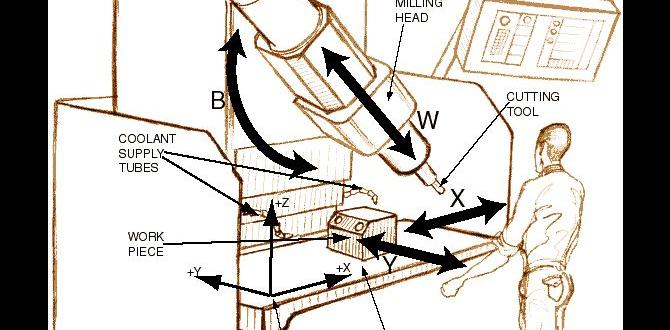

Tool design modifications for improved chip management. Adjusting machining parameters for optimal performance.To manage lathe chip deflection, you can make some smart changes. Start with tool design. A well-designed tool helps control chip flow. This keeps chips from flying around, which can be messy and unsafe. Also, adjust your machining settings. For example, use the right speed and depth of cut. This helps in making smoother chips. Here are a few strategies:

- Improve tool geometry.

- Use sharper tools for clean cuts.

- Optimize cutting speed.

How can chip deflection be reduced during machining?

Adjusting tools and machining parameters helps greatly. Better designs and settings lead to less deflection and efficient cutting.

Case Studies: Successful Management of Chip Deflection

Examples of industries affected by chip deflection. Solutions implemented and results achieved.Many industries face chip deflection problems. For example, the automotive sector often struggles with this issue. When chips fly incorrectly, they can ruin parts. This leads to wasted time and money. To fix these issues, companies have tried several solutions:

- Adjusting cutting speeds.

- Using different materials for tools.

- Improving machine settings.

Results showed fewer defects and better product quality. One factory reported a 30% decrease in waste after making these changes. Proper management of chip deflection helps ensure success.

What are common industries affected by chip deflection?

Industries like automotive, aerospace, and manufacturing often deal with chip deflection issues. They face challenges in ensuring precision and quality in their products.

Future Trends in Lathe Technology Addressing Chip Deflection

Innovations in tooling and machine design. Insights into smart manufacturing solutions for chip control.New inventions in lathe tools and machine designs are making big changes in how we tackle chip deflection. Smart manufacturing is stepping in like a superhero to save the day! With real-time monitoring, machines can adjust instantly, keeping chips in line. Imagine your lathe has eyes! These innovations help reduce waste and increase quality, which means making more parts and spending less time fixing mistakes. It’s like Sherlock Holmes for your lathe, solving problems before they happen!

| Innovation Type | Description |

|---|---|

| Tooling Design | New shapes and materials that improve cutting performance. |

| Smart Technology | Real-time data to control chip movement. |

Conclusion

In conclusion, lathe chip deflection can cause problems like poor accuracy and tool wear. You can minimize these issues by adjusting cutting speed, tool angles, and workpiece support. We recommend trying different settings to see what works best for your machine. For more tips, consider reading guides on chip management and machining techniques. Let’s make your lathe work better together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Chip Deflection Issues:Sure! Here are answers to some questions about lathe chip deflection issues. When we use a lathe, it spins material to shape it. Sometimes, chips can bend in the wrong direction. This happens because of how hard we push or the speed we use. To fix this, we can adjust our tools or how we work.

Sure! Please provide the question you want me to answer.

What Are The Primary Factors That Contribute To Chip Deflection During The Machining Process On A Lathe?Chip deflection happens when tiny pieces of metal fly off while we cut. One reason is how fast we are spinning the lathe. If we cut too fast, chips can bounce around. The sharpness of our cutting tool also matters. A dull tool makes more messy chips. Finally, the way we set up the lathe can change how chips behave.

How Can Chip Deflection Impact The Quality Of The Finished Workpiece In Turning Operations?When we turn metal or wood, small pieces called chips get cut away. If these chips bounce around too much, they can scratch the workpiece. This makes the surface rough instead of smooth. We want our finished piece to look nice and be the right size. So, controlling chip deflection helps keep the workpiece perfect!

What Techniques Or Tools Can Be Employed To Minimize Chip Deflection When Machining Different Materials?To reduce chip deflection while machining, you can use a few helpful tools and techniques. First, choose sharp cutting tools to make clean cuts. Second, support the material well so it doesn’t move. You can also adjust the speed of the machine to find the best settings. Lastly, using coolant can help keep the material steady and cool.

How Does The Geometry Of The Cutting Tool Influence Chip Formation And Deflection In Lathe Operations?The shape of the cutting tool helps it cut metal better. If the tool is sharp and has a good angle, it makes smaller chips. This is great because smaller chips are easier to manage. If the tool is not shaped right, it can bend or deflect, which can cause problems. So, a well-designed tool cuts smoothly and keeps everything on track.

What Role Does Cutting Speed And Feed Rate Play In Chip Deflection And Overall Machining Performance On A Lathe?When you use a lathe, cutting speed is how fast the tool moves through the material. A higher cutting speed can make chips fly off better, which helps keep the work clean. The feed rate is how fast the tool goes forward. If the feed rate is too high, it can push the chips out too hard and make them deflect. This affects how smooth the cut is and how well the machine works overall.