Have you ever watched a lathe at work? It’s like magic as it spins and shapes metal. But what keeps that magic safe? The lathe chuck! Tightening the lathe chuck in the right sequence is crucial for smooth operation.

Imagine your favorite toy being made from a block of wood. Now picture that block spinning rapidly, slowly turning into something amazing. If the chuck isn’t tight enough, things could go wrong. How do you make sure that doesn’t happen? By following the right tightening sequence!

Here’s a fun fact: a perfectly tightened chuck can help your tools last longer and perform better! It’s all about getting that balance just right. So, why don’t we explore how to tighten the lathe chuck correctly? Your projects might just turn out even better!

Lathe Chuck Tightening Sequence: A Step-By-Step Guide

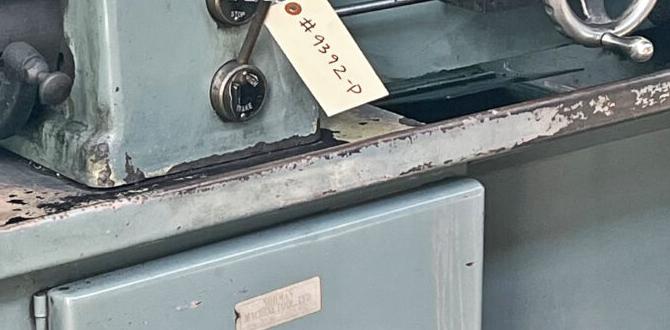

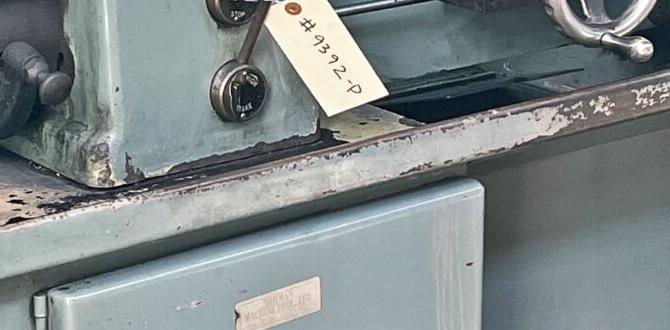

Lathe Chuck Tightening Sequence

When using a lathe, knowing the correct chuck tightening sequence is essential. It ensures that your workpiece stays secure and balanced while spinning. Start by tightening opposite screws. This technique prevents uneven pressure. Did you know? An incorrectly tightened chuck can lead to accidents or poor work quality! Following a clear sequence keeps everything safe and precise. Make sure to practice this method for the best results every time you work on your lathe.Importance of Proper Tightening Sequence

Ensures precision in machining operations. Prevents component damage and tool wear.Getting the tightening sequence right is very important. It makes sure your machine works smoothly. A correct sequence ensures precision during machining. This helps you make exact shapes and sizes for your projects. Also, following this can prevent component damage. It keeps your tools from wearing out quickly. A little attention can save you time and money in the long run.

Why is the tightening sequence important?

It helps machines work better and last longer.

Key Effects:

- Improves quality of work

- Reduces repair costs

- Increases tool lifespan

Step-by-Step Tightening Sequence

Detailed tightening steps for threejaw chucks. Specific sequence for fourjaw chucks, highlighting adjustments.Tightening a lathe chuck requires careful steps. For a three-jaw chuck, start by tightening each jaw slightly in a sequence. This ensures even pressure and holds the workpiece safely. Follow this order:

- Tighten jaw 1

- Tighten jaw 2

- Tighten jaw 3

In contrast, a four-jaw chuck needs precise adjustments. Tighten each jaw in a specific way for balance:

- Tighten jaw A

- Adjust jaw B

- Tighten jaw C

- Adjust jaw D

Remember, small turns are key. This method keeps everything secure and straight.

How do you tighten a lathe chuck correctly?

You tighten a lathe chuck by working across the jaws evenly. Start with one jaw, then move to the next. This keeps the workpiece steady.

Common Mistakes to Avoid

Identifying overtightening and its consequences. Issues caused by improper sequence execution.It’s important to avoid common mistakes when using a lathe chuck. Overtightening can lead to problems. It may damage your materials or cause the lathe to break. Proper tightening helps keep everything safe and working well.

- Check the tightness often.

- Follow the tightening sequence carefully.

- Listen for unusual sounds while operating.

Always remember: mistakes can lead to accidents. Take your time to do things right!

What happens with overtightening?

Overtightening can crack your workpiece and ruin your project. It can also make the chuck harder to adjust later.

What problems come from wrong sequence execution?

Using the wrong sequence can cause uneven pressure on the chuck. This may lead to wobbling and inaccuracy when cutting.

Tools and Equipment for Tightening

Recommended tools for optimal tightening (e.g., torque wrenches). Safety gear and practices to consider while tightening.Using the right tools is key when tightening a lathe chuck. Start with a torque wrench. It ensures you apply the correct force. Other helpful tools include wrenches and pliers. Always prioritize safety. Wear gloves to protect your hands. Safety goggles will keep your eyes safe from debris. Follow these tools and safety rules for effective and safe tightening.

- Torque wrench for proper force

- Wrenches for grip

- Pliers for adjustments

What tools do I need for tightening?

You need a torque wrench, wrenches, and pliers to tighten correctly.

Safety gear to wear:

- Gloves

- Goggles

Maintenance Tips for Lathe Chucks

Regular checks and cleaning procedures. Importance of lubrication and its effect on chuck performance.To keep your lathe chuck in great shape, routine checks and cleaning are essential. Look for dirt and chips in the chuck regularly. Clean it using a soft cloth and mild cleaner to avoid scratches. Proper lubrication is also vital. Lubricated chucks work better and last longer. Running your lathe without lubrication can cause wear and tear. To sum it up, clean and lubricate your lathe chuck often for optimal performance.

Why is lubrication important for lathe chucks?

Lubrication helps reduce friction. It improves movement and extends the chuck’s life. Regular lubrication ensures smooth operation.

Maintenance Checklist:

- Check for dirt and chips weekly.

- Clean with a soft cloth.

- Lubricate moving parts every month.

Practical Applications of Chuck Tightening

Examples of machining projects benefiting from correct tightening. Case studies demonstrating the consequences of poor practices.Using the right tightening technique can make all the difference in machining projects. For example, if a lathe chuck is tightened correctly, projects like creating gears or shafts will run smoothly. On the flip side, improper tightening can lead to mistakes, like wobbly parts or even broken tools. This can slow down work and cost money! Check out these entertaining examples:

| Project Type | Effect of Tightening |

|---|---|

| Gears | Correct tightening means smooth rotation; loose gears can lead to chaos! |

| Shafts | Properly tightened shafts last longer; bad tightening can break them faster than a bad joke! |

In short, when you tighten properly, everything works like magic. If not, you might find yourself wishing you had a time machine to fix your mistakes!

Expert Insights and Best Practices

Tips from experienced machinists on effective tightening. Recommendations for training and skill development in chuck handling.Experienced machinists have a few gems of wisdom when it comes to tightening a lathe chuck. First, remember to tighten opposite pairs instead of going in a circle. This keeps it snug and safe. Think of it as a friendship bracelet; it needs balanced pulls! Also, practice makes perfect. Consider training sessions on chuck handling to boost your skills. Hands-on practice can turn a rookie into a pro quicker than you can say “precision machining!”

| Tip | Explanation |

|---|---|

| Tighten in pairs | Tighten opposite jaws to keep the chuck even. |

| Practice regularly | Hands-on experience helps improve your skills. |

Always keep learning! Attending workshops can sharpen your understanding. Plus, it’s a great way to meet fellow enthusiasts. So, put on your workshop apron, and let’s get chucked!

Conclusion

In conclusion, remember that the lathe chuck tightening sequence is vital for safe and accurate machining. Always tighten the jaws in a specific order to ensure even pressure. This prevents workpiece damage and improves precision. You can practice this sequence on your lathe. For more tips, read additional resources or watch instructional videos to enhance your skills!FAQs

What Is The Recommended Tightening Sequence For A Lathe Chuck To Ensure Even Clamping Pressure?To tighten a lathe chuck well, start with the top jaw, then go to the bottom left, and next to the bottom right. This order helps keep everything even and tight. Make sure you use your hands to turn each one a little at a time. Check that it’s all snug, but be careful not to over-tighten. Doing this helps hold your workpiece securely.

How Does The Tightening Sequence Of A Lathe Chuck Affect The Accuracy And Stability Of The Workpiece?When you tighten a lathe chuck, the order you choose matters. If you tighten it in a star pattern, it holds the piece better. This helps keep the workpiece steady and makes it more accurate. If you don’t, it might wobble or not cut right. So, always remember to tighten from the center outwards!

Are There Specific Guidelines For Tightening A Three-Jaw Versus A Four-Jaw Lathe Chuck?Yes, there are different ways to tighten a three-jaw and a four-jaw lathe chuck. For a three-jaw chuck, you turn the handle to make all the jaws move at once. This makes it easy because you don’t have to worry about the order. For a four-jaw chuck, you tighten each jaw separately. It’s important to do this evenly, so the piece stays steady.

What Are The Potential Consequences Of Not Following The Proper Tightening Sequence On A Lathe Chuck?If you don’t follow the right order when tightening a lathe chuck, it can cause problems. The chuck might not hold the piece tightly, making it slip or move. This can lead to accidents, like the piece getting damaged or you getting hurt. It also might wear out the chuck faster, costing you more to fix it. Always tighten it correctly to stay safe and keep your tools in good shape!

How Can You Determine If A Lathe Chuck Is Properly Tightened After Following The Recommended Sequence?To check if a lathe chuck is tight, you can give it a little tug. If it doesn’t move, it’s tight enough. You can also look for any gaps between the chuck and the workpiece. If there are no gaps, that’s a good sign too. Always be careful and follow safety rules while doing this!