Have you ever wondered how metal parts are shaped so precisely? That’s where a lathe collet system comes in! This clever device grips the metal firmly while the machine carves away. Imagine a sculptor using the right tools to create a masterpiece. In metalworking, the lathe does just that.

The lathe collet system holds the workpiece securely. It allows the metal lathe to shape and cut without any wobbling. This means better accuracy! When you want a perfect fit or a smooth finish, this system is a must-have.

Here’s a fun fact: using a lathe can be just like baking! You need the right ingredients and tools to create something great. In this case, the lathe collet system is one of those essential tools. Are you curious to learn how it works? Let’s dive deeper into the fascinating world of metal lathes!

Understanding The Lathe Collet System For Metal Lathes

Lathe Collet System for Metal Lathes

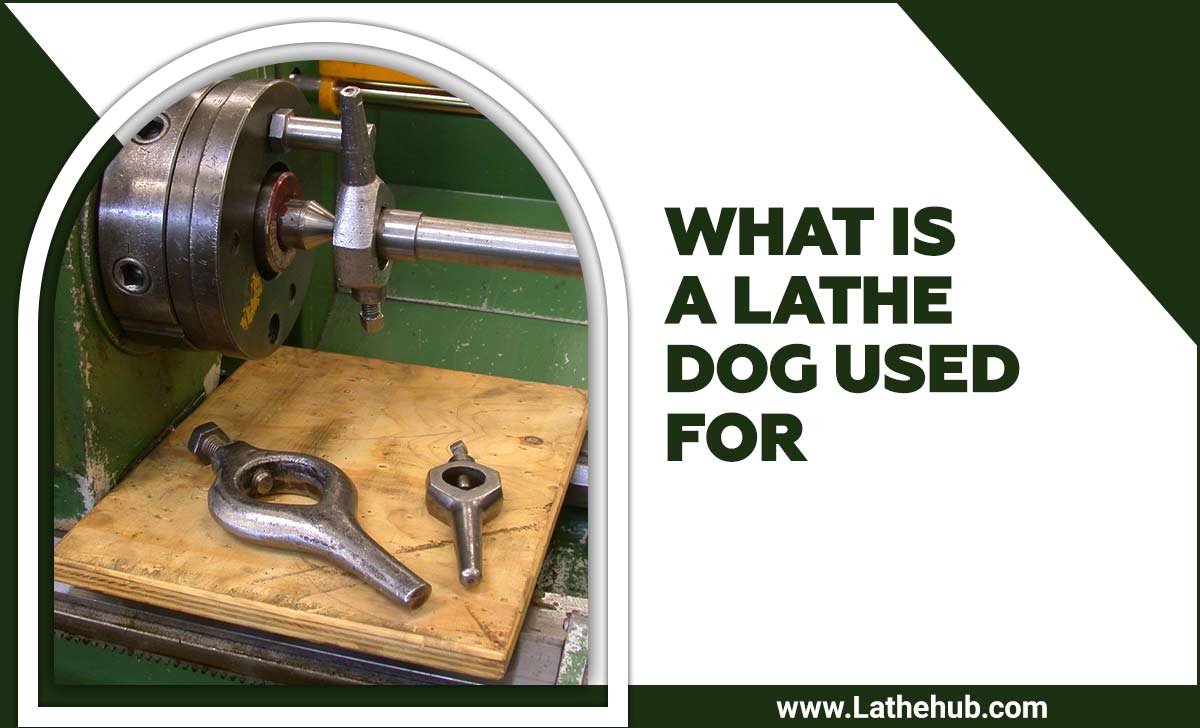

Using a lathe collet system improves precision for metal lathes. Collets hold tools tightly, so they don’t slip during work. Have you ever noticed how a loose tool can ruin a project? With collets, you avoid that problem. They are easy to change and come in various sizes. A fun fact: Collets can grip shapes like hex or square, not just round! This flexibility makes them perfect for detailed jobs. Discover how this simple tool can elevate your metalwork!What is a Lathe Collet System?

Definition and purpose of collet systems in metal lathes. Differences between collets and other workholding methods.A lathe collet system is like a trusty sidekick for metal lathes. It holds workpieces securely during machining, ensuring they don’t go on a wild ride. Collets are special grips that close around a piece tightly, unlike other methods, like chucks, which can be a bit lazy. Collets offer quick changes and better precision, making them popular among machinists. Bonus fun fact: they save time, so you can spend more time pretending to be a superhero in the workshop!

| Workholding Method | Advantages | Disadvantages |

|---|---|---|

| Collet | Fast, precise holding | Limited to certain sizes |

| Chuck | Versatile, can hold various shapes | Slower to change, less precision |

Benefits of Using a Collet System

Increased precision and accuracy in machining. Enhanced clamping force and stability during operation.Using a collet system provides clear advantages. It helps with increased precision and accuracy in machining tasks. This means better-fitting parts and less waste. Additionally, it offers enhanced clamping force. This keeps materials stable and secure during operation. Therefore, you get smoother cuts and improved results.

What are the benefits of a collet system?

The benefits include greater precision and stronger grip on materials during machining. This means you create better products with fewer mistakes.

- Better accuracy in cutting

- Less vibration while working

- More reliable finishes

Choosing the Right Collet for Your Metal Lathe

Factors to consider when selecting a collet (e.g., workpiece size, material). Compatibility with different lathe models.Picking the right collet can feel like choosing ice cream flavors—so many options! First, think about the size of your workpiece. A smaller collet can hold tiny pieces, while a larger one is better for big stuff. Next, consider the material you’ve got. Different materials need different grips! Also, check if your collet works with your lathe model. Not every collet fits all lathes. It’s like trying to fit a square peg in a round hole—doesn’t work! Here’s a quick table to help you out:

| Lathe Model | Compatible Collet Sizes |

|---|---|

| Model A | 1/2”, 5/8” |

| Model B | 3/4”, 1” |

| Model C | 1/8”, 1/4” |

So remember, size and material matter, and always check compatibility. It’ll save you time and keep your projects spinning smoothly!

How to Set Up a Lathe Collet System

Stepbystep guide to proper collet installation. Common mistakes to avoid during setup.Setting up a lathe collet system can be easy if you follow the steps. First, clean the collet and spindle. Then, insert the collet into the spindle securely. Next, tighten the nut to hold the collet in place. Remember these common mistakes to avoid:

- Not cleaning parts before setup.

- Over-tightening the collet nut.

- Forgetting to check for proper alignment.

Taking your time during setup helps prevent problems later. A small mistake can affect your work.

What is the purpose of a collet system?

The collet system holds tools firmly while the lathe turns. This allows for greater accuracy in cutting and shaping metal.

Maintenance Tips for Lathe Collet Systems

Routine checks and cleaning practices to prolong lifespan. Troubleshooting common issues with collet systems.Keeping your lathe collet system in top shape is like brushing your teeth—important and often ignored! Regularly check for dirt and dust because they love to party in there. A quick wipe can extend its life. If things seem off, check the collet for damage. If it’s wiggly, it’s time to replace it! Always ensure it’s tightened properly; we don’t want it flying off like a bird in a cat’s paws.

| Maintenance Tips | Details |

|---|---|

| Routine Checks | Inspect for debris and scratches. |

| Cleaning | Wipe it down after every use. |

| Troubleshooting | Replace loose or damaged collets. |

Comparing Collet Systems to Other Workholding Solutions

Pros and cons of collets versus chucks and vises. Scenarios where collets outperform alternative methods.Collet systems offer some nifty advantages over chucks and vises, but they also have their quirks. For example, collets can grip your workpiece more tightly, which is great for precision. However, they might not be as suitable for larger items. Chucks are super versatile for holding different shapes, but they often leave room for slips. If you’re working on tiny parts, though, collets shine like a superhero! Let’s take a peek at the scorecard:

| Type | Pros | Cons |

|---|---|---|

| Collet | Precision, tight grip | Narrow range |

| Chuck | Versatile, good for larger parts | Can slip |

| Vise | Stable hold | Less flexible |

In short, if you want precision for smaller parts, collets are your best buddies! Just be careful not to drop them—they’re not the best at catching. That’s a job for your cat, right?

Real-World Applications of Lathe Collet Systems

Industries and projects that benefit from collet systems. Case studies or examples showcasing successful implementation.Many industries rely on lathe collet systems for precise work. These systems hold different materials tightly and securely. They are especially useful in:

- Manufacturing – For creating machine parts.

- Aerospace – To build safe and reliable components.

- Automotive – For crafting engine pieces.

- Jewelry – Allowing intricate designs to be made efficiently.

Case studies show companies improved their production time by 30% when using collet systems. This helps them create high-quality products faster. Clearly, these systems have a big impact on many successful projects.

What are some successful examples of lathe collet systems?

Many businesses report great results with collet systems. For example, one aerospace company reduced errors by 25%, boosting safety. A jewelry maker improved design quality and speed by 40%. These stories show how useful lathe collet systems can be!

Upgrade Options for Lathe Collet Systems

Advanced features and accessories available for modern collet systems. Recommendations for enhancing performance and versatility.Modern lathe collet systems offer exciting features and useful accessories. Upgrading these can boost both performance and flexibility. Consider adding:

- Collet wrenches for quick changes.

- Specialized collets to hold different shapes.

- Adapter plates for varied stock sizes.

- Adjustable stops for precise measurements.

These upgrades help you work faster and more accurately. A skilled worker can produce better results with the right tools, making projects smoother and more enjoyable.

What features enhance lathe collet systems?

Advanced features like self-centering collets and quick-change systems greatly improve efficiency.

Frequently Asked Questions About Lathe Collet Systems

Answers to common queries and misconceptions. Additional resources for further learning and support.Many people have questions about lathe collet systems. These questions help clear up any confusion. Here are some frequently asked questions:

What is a lathe collet system?

A lathe collet system is a tool holder. It grips the workpiece tightly. This helps make precise cuts. Collets come in different sizes for various tasks.

Why use a collet instead of a chuck?

Collets provide better accuracy. They reduce vibrations, making your project smoother. This can lead to better results.

Additional Resources:

- Online tutorials: Watch videos to learn more.

- Forums: Join discussions with other users.

- User manuals: Read guides for specific machines.

Conclusion

In conclusion, a lathe collet system is essential for precision in metal lathe work. It holds your workpiece securely and allows for quick changes. Understanding this system helps you achieve better results in your projects. Now, practice using a lathe collet system, or read more to expand your skills. Let’s get started and make amazing things together!FAQs

What Are The Advantages Of Using A Collet System Over Standard Chucks In A Metal Lathe?Using a collet system on a metal lathe has some great advantages. First, collets hold the metal piece more firmly, so it doesn’t slip while you work. Second, they can fit many different shapes and sizes. This makes it easier to switch between jobs quickly. Lastly, collets help create smoother and more precise cuts.

How Do You Select The Appropriate Collet Size For Different Workpiece Diameters In A Lathe?To pick the right collet size for your workpiece, start by measuring the diameter of the piece. Then, choose a collet that matches that size. If the piece is too big for a smaller collet, grab a larger one. Remember, the collet needs to hold the workpiece snugly while it spins. Always check the collet’s size before you start working.

What Materials Are Commonly Used For Lathe Collets, And How Do They Affect Performance?Lathe collets are often made from steel, aluminum, or plastic. Steel is strong and durable, making it great for heavy work. Aluminum is lighter and helps machines run faster, but it may not be as strong. Plastic is light and less expensive, but it might not hold up for tough jobs. Choosing the right material helps the lathe work better and last longer.

Can A Lathe Collet System Accommodate Both Round And Non-Round Workpieces, And If So, How?Yes, a lathe collet system can hold both round and non-round workpieces. Collets are special grips that squeeze tightly around the item you’re working on. For round pieces, they fit perfectly because they’re shaped like circles. For non-round shapes, there are special collets that can grab onto different shapes, like squares or rectangles. This lets you work on different kinds of items easily!

What Are Some Common Troubleshooting Tips For Issues Related To Collet Gripping And Alignment On Metal Lathes?If your collet isn’t gripping well, check if it’s clean and free from debris. Make sure the collet is the right size for your workpiece. If things aren’t lined up, check that your lathe is level. You can also tighten the collet more to secure your piece better. Always remember to be careful when working with machines!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Over Standard Chucks In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system on a metal lathe has some great advantages. First, collets hold the metal piece more firmly, so it doesn’t slip while you work. Second, they can fit many different shapes and sizes. This makes it easier to switch between jobs quickly. Lastly, collets help create smoother and more precise cuts.”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Collet Size For Different Workpiece Diameters In A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To pick the right collet size for your workpiece, start by measuring the diameter of the piece. Then, choose a collet that matches that size. If the piece is too big for a smaller collet, grab a larger one. Remember, the collet needs to hold the workpiece snugly while it spins. Always check the collet’s size before you start working.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Lathe Collets, And How Do They Affect Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe collets are often made from steel, aluminum, or plastic. Steel is strong and durable, making it great for heavy work. Aluminum is lighter and helps machines run faster, but it may not be as strong. Plastic is light and less expensive, but it might not hold up for tough jobs. Choosing the right material helps the lathe work better and last longer.”}},{“@type”: “Question”,”name”: “Can A Lathe Collet System Accommodate Both Round And Non-Round Workpieces, And If So, How? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, a lathe collet system can hold both round and non-round workpieces. Collets are special grips that squeeze tightly around the item you’re working on. For round pieces, they fit perfectly because they’re shaped like circles. For non-round shapes, there are special collets that can grab onto different shapes, like squares or rectangles. This lets you work on different kinds of items easily!”}},{“@type”: “Question”,”name”: “What Are Some Common Troubleshooting Tips For Issues Related To Collet Gripping And Alignment On Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your collet isn’t gripping well, check if it’s clean and free from debris. Make sure the collet is the right size for your workpiece. If things aren’t lined up, check that your lathe is level. You can also tighten the collet more to secure your piece better. Always remember to be careful when working with machines!”}}]}