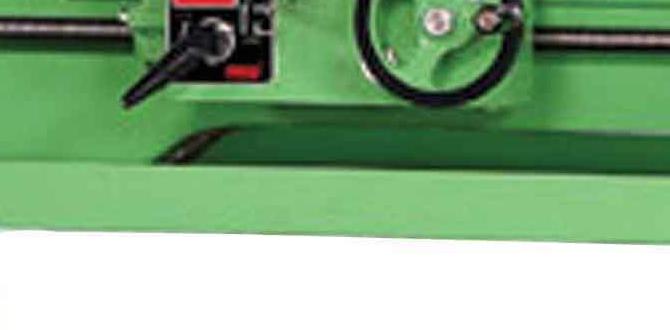

Have you ever wondered how metal lathe machines work so perfectly? One secret lies in the lathe collet system. This system helps hold and align the workpiece tightly. It ensures that everything spins correctly without wobbling. Imagine trying to bake a cake. If your ingredients are mixed well, the cake will turn out great. In the same way, proper lathe alignment creates better, more precise parts.

Think about it: what happens if your lathe isn’t aligned right? Cutting tools may not slice evenly. This can lead to parts that don’t fit together, which can be very frustrating! A well-aligned lathe can make a big difference in your projects.

Fun fact: even small misalignments can lead to major mistakes in metalworking. Understanding how to set up and use a lathe collet system correctly is key to successful machining. Ready to learn more about how to align your metal lathe effectively? Let’s dive in!

Lathe Collet System: Essential For Metal Lathe Alignment

Understanding Lathe Collet System Metal Lathe Alignment

A lathe collet system is critical for metal lathe alignment. Proper alignment ensures accuracy during machining. Did you know that even a tiny misalignment can ruin your work? The collet holds the workpiece tightly, allowing for precise cuts. If you check alignment regularly, you can avoid costly mistakes. Proper setup makes your projects smoother and results more reliable. This knowledge helps both beginners and skilled machinists achieve better outcomes. Curious about how a simple tool can change your results?Understanding Lathe Collet Systems

Definition and components of lathe collet systems. Types of collets and their applications.Lathe collet systems are clever tools used in metal lathes to hold workpieces tightly. They come in different shapes and sizes, making them perfect for various jobs. The main parts of a collet system include the collet itself, the chuck, and the drawbar. Each type has its own special trick, like the ER collet, great for small parts, or the OCS collet, perfect for larger items. Just imagine a superhero team of tools, ready to save the day in the workshop!

| Type of Collet | Application |

|---|---|

| ER Collet | Small parts, high precision |

| OCS Collet | Larger items and heavier workloads |

| 4-Jaw Collet | Inequal shapes, custom shapes |

Importance of Metal Lathe Alignment

Effects of misalignment on machining precision. Benefits of proper alignment for metal lathes.Proper metal lathe alignment is vital for achieving precision. If your lathe is misaligned, your parts may not turn out as expected. This can lead to wasted materials and time, and nobody wants a wonky widget, right? Proper alignment means smoother operation and tighter tolerances. It can improve the quality of your work and keep your machine running longer. Plus, a well-aligned lathe might just make your neighbors a bit jealous of your skills!

| Effects of Misalignment | Benefits of Proper Alignment |

|---|---|

| Poor precision | Increased accuracy |

| Wasted materials | Better quality |

| Longer machining times | Quicker production |

| Higher risk of damage | Lower maintenance costs |

Common Issues with Lathe Collet Systems

Problems associated with collet wear and tear. Identifying and resolving colletrelated issues.Collet systems can be a bit dramatic, like a season finale in a soap opera. One main issue is wear and tear, which means the collet might not grip as tightly. This can lead to sloppy work, and nobody wants wobbly pieces! Spotting problems is mostly about paying attention. If you see any cracks or odd shapes, it’s time to take action. Regular checks can help! If a collet is tired, replacing it can do wonders. Keep your lathe happy, and it’ll return the favor.

| Common Issues | Solution |

|---|---|

| Wear and tear | Replace the worn collet |

| Cracks or deformities | Inspect and replace immediately |

| Poor grip | Clean or replace |

Techniques for Accurate Metal Lathe Alignment

Stepbystep process for aligning a metal lathe. Tools required for precision alignment.Aligning a metal lathe is important for precision work. Follow these steps for accuracy:

- First, check the lathe’s level. Use a spirit level on the bed.

- Then, adjust the tailstock alignment. Look through the spindle and ensure they line up.

- Next, inspect the cross-slide for any misalignment. Adjust as needed.

- Finally, test with a dial indicator to confirm precision.

For proper alignment, you’ll need:

- A spirit level

- Dial indicator

- Wrenches for adjustments

What tools do you need for lathe alignment?

You need a spirit level, dial indicator, and wrenches for proper alignment.

Following these steps ensures your lathe is ready for precise work. A well-aligned lathe helps create accurate parts, making your projects smoother and more enjoyable.

Best Practices for Maintaining Collet Systems

Regular inspection and maintenance procedures. Tips for prolonging the lifespan of collets.To keep your collet systems in tip-top shape, regular checks are a must. Look for wear and tear every few weeks. This prevents small problems from becoming big headaches. Want to extend your collets’ lifespan? Give them a gentle clean, and avoid over-tightening. They aren’t weightlifters! A safe storage spot keeps them happy too. Here’s a quick table to help you:

| Maintenance Tip | Details |

|---|---|

| Inspect Regularly | Check for damage and dirt every few weeks. |

| Clean Gently | Use a soft cloth to avoid scratches. |

| Avoid Over-tightening | Keep it snug, but not crazy tight! |

| Store Properly | Keep collets in a safe, dry place. |

Following these simple steps can keep your collet systems running smoothly and make your lathe life a lot easier!

Comparative Analysis of Collet Systems and Other Workholding Methods

Comparison with chuck systems and fixtures. Pros and cons of using collets over traditional methods.When comparing collet systems to chuck systems and fixtures, each has its quirks. Chuck systems, for example, are like that friend who tries to hold everything together; they’re strong but sometimes a bit clunky. On the flip side, collets are the nimble dancers of workholding. They grip the workpiece snugly and can be changed quickly. However, they might not hold larger pieces as firmly. Let’s look at the pros and cons:

| Method | Pros | Cons |

|---|---|---|

| Collet Systems | Quick changes & Precise grip | Limited size range |

| Chuck Systems | Strong hold | Slower adjustments |

| Fixtures | Very stable | Time-consuming setup |

Choosing the right method can be crucial. While collets shine in speed and precision, chucks are champions of strength. And fixtures? Well, they take their time but deliver rock-solid stability. So, go ahead and pick what suits your spinning adventures!

Advanced Techniques for Collet System Optimization

Custom collet solutions for specialized operations. Integration of technology in collet systems for enhanced performance.Custom collet solutions make special tasks easier. These designs fit unique needs for different projects. They help create precise shapes and sizes.

Technology improves collet systems. Smart features help them work better and faster. This means less time wasted and more quality production.

- Improved grip for better performance.

- Less vibration leads to smoother cuts.

- Better accuracy with advanced sensors.

Using new tech makes metal lathe work exciting. It shows how innovation helps in crafting.

What are custom collet solutions?

Custom collet solutions are specially designed parts that help in various tasks by fitting specific needs, improving the quality of work.

How does technology enhance collet systems?

Technology enhances collet systems by adding smart features that improve performance, making the work more efficient and effective.

Case Studies: Successful Implementations of Collet Systems

Examples of industries benefiting from collet systems. Lessons learned from collet system failures and successes.Many companies use collet systems to improve their manufacturing. These systems grip tools tightly, allowing for smoother and faster operation. For example, the auto industry benefits from precise parts. The aerospace field also relies on collet systems for accurate machining. However, not all implementations succeed. Some lessons learned include:

- Regular maintenance is crucial to avoid malfunctions.

- Proper training helps staff use systems effectively.

- Testing new setups can prevent costly mistakes.

With the right strategies, businesses can thrive using collet systems.

Why are collet systems important in manufacturing?

Collet systems provide better accuracy, reduce waste, and increase production speed. Companies can save time and money by using these systems correctly.

Future Trends in Lathe Collet Systems and Alignment Technology

Innovations in collet design and manufacturing. Predictions for advancements in lathe alignment techniques.New ideas are changing collet design and how we align lathes. Manufacturers use better materials to create stronger, lighter collets. These changes help machines work faster and more accurately. Soon, we might see advanced alignment techniques that use sensors. These can make aligning lathes easier and quicker. As technology evolves, we can expect better performance and efficiency in metalworking.

What innovations can we expect in collet design?

We will likely see more durable materials, better grip designs, and smart technology integration.

How will lathe alignment techniques improve?

- Increased use of automated systems

- Greater precision with laser technology

- Faster setup times through modern tools

Conclusion

In summary, a lathe collet system is crucial for proper metal lathe alignment. It helps hold your workpiece securely, ensuring accuracy as you cut. We can improve our projects by regularly checking alignment and using quality collets. For more help, consider reading guides on lathe maintenance and techniques. Let’s keep exploring and improving our metalworking skills together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet System And Metal Lathe Alignment:Sure! A lathe collet system helps hold a piece of metal tightly while you shape it. Proper alignment means the lathe works well and makes smooth cuts. To align your lathe, you can check the parts and make sure they are straight. Good alignment helps you do better work, and it keeps the tools safe. Always be careful and follow instructions when using a lathe!

Sure! Please provide the question you want me to answer.

What Is The Importance Of Aligning The Collet System In A Metal Lathe For Achieving Precision In Machining?Aligning the collet system in a metal lathe is really important. When it’s lined up correctly, the tool cuts the metal evenly. This means your finished piece will be just the way you want it. If it’s not aligned, the cuts can be wobbly or uneven. So, taking time to align it helps you make better and more accurate parts.

How Do You Check For Alignment Issues In A Lathe’S Collet System, And What Tools Are Typically Used For This Purpose?To check for alignment issues in a lathe’s collet system, you can use a few simple tools. First, you need a dial indicator. This tool helps you see if the collet is straight and balanced. You can also use a ruler or a caliper to measure any gaps. If everything lines up correctly, your collet system is good to go!

What Are The Common Types Of Collets Used In Metal Lathes, And How Does Each Type Impact Alignment?Common types of collets used in metal lathes are 3-jaw, 4-jaw, and collet chucks. A 3-jaw collet holds round items tightly and is easy to use. A 4-jaw collet can hold odd shapes and helps with better alignment. Collet chucks fit specific sizes and provide a very snug fit. Each type helps keep the metal in the right place while we cut or shape it.

Can Misalignment Of The Collet System Lead To Defects In Finished Parts, And If So, What Specific Issues Might Arise?Yes, if the collet system is not lined up correctly, it can cause problems. You might get parts that aren’t the right shape or size. Sometimes, the edges can be rough or uneven. This can make the finished parts not work well. So, it’s important to keep everything properly aligned.

What Are The Best Practices For Setting Up And Maintaining The Collet System In A Metal Lathe To Ensure Optimal Performance And Alignment?To set up the collet system on a metal lathe, first, clean the collet and chuck well. You should always check that they fit tightly together. Use the proper size collet for your workpiece. When you tighten the collet, make sure it grips the piece firmly but not too hard. Finally, check the alignment by spinning the lathe to see if it runs smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Collet System And Metal Lathe Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe collet system helps hold a piece of metal tightly while you shape it. Proper alignment means the lathe works well and makes smooth cuts. To align your lathe, you can check the parts and make sure they are straight. Good alignment helps you do better work, and it keeps the tools safe. Always be careful and follow instructions when using a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Importance Of Aligning The Collet System In A Metal Lathe For Achieving Precision In Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Aligning the collet system in a metal lathe is really important. When it’s lined up correctly, the tool cuts the metal evenly. This means your finished piece will be just the way you want it. If it’s not aligned, the cuts can be wobbly or uneven. So, taking time to align it helps you make better and more accurate parts.”}},{“@type”: “Question”,”name”: “How Do You Check For Alignment Issues In A Lathe’S Collet System, And What Tools Are Typically Used For This Purpose?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check for alignment issues in a lathe’s collet system, you can use a few simple tools. First, you need a dial indicator. This tool helps you see if the collet is straight and balanced. You can also use a ruler or a caliper to measure any gaps. If everything lines up correctly, your collet system is good to go!”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Collets Used In Metal Lathes, And How Does Each Type Impact Alignment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common types of collets used in metal lathes are 3-jaw, 4-jaw, and collet chucks. A 3-jaw collet holds round items tightly and is easy to use. A 4-jaw collet can hold odd shapes and helps with better alignment. Collet chucks fit specific sizes and provide a very snug fit. Each type helps keep the metal in the right place while we cut or shape it.”}},{“@type”: “Question”,”name”: “Can Misalignment Of The Collet System Lead To Defects In Finished Parts, And If So, What Specific Issues Might Arise?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, if the collet system is not lined up correctly, it can cause problems. You might get parts that aren’t the right shape or size. Sometimes, the edges can be rough or uneven. This can make the finished parts not work well. So, it’s important to keep everything properly aligned.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Setting Up And Maintaining The Collet System In A Metal Lathe To Ensure Optimal Performance And Alignment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the collet system on a metal lathe, first, clean the collet and chuck well. You should always check that they fit tightly together. Use the proper size collet for your workpiece. When you tighten the collet, make sure it grips the piece firmly but not too hard. Finally, check the alignment by spinning the lathe to see if it runs smoothly.”}}]}