Have you ever watched a metal lathe spin and wondered how it works? A lathe collet system makes this magic happen. It holds the workpiece steady while the machine shapes it into amazing designs. This process can seem complicated, but automation changes everything.

Imagine a factory where robots do the hard work. They use lathe collet systems to tackle big jobs quickly and easily. This type of automation helps reduce mistakes. It also gives workers more time to think and create new ideas.

Did you know that using lathe collet systems can speed up production? It can save companies both time and money. Many businesses are excited about this technology. It combines old techniques with modern automation for great results.

Curious about how this all fits together? Let’s dive into the world of lathe collet systems and discover the future of metal lathe automation!

Understanding Lathe Collet System For Metal Lathe Automation

Understanding the Lathe Collet System in Metal Lathe Automation

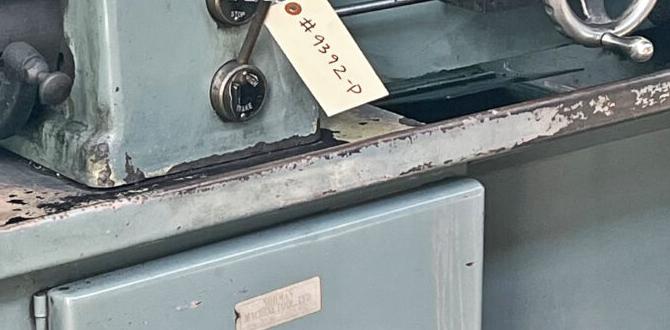

The lathe collet system is essential for metal lathe automation. It helps securely hold various workpieces, ensuring precise machining. By using collets, you can switch tools and materials quickly. This feature saves time and boosts productivity. Imagine a busy workshop where every second counts; efficient automation can make a big difference. Did you know that a well-implemented collet system can reduce setup errors significantly? This is why many industries rely on it for their metalworking needs.What is a Lathe Collet System?

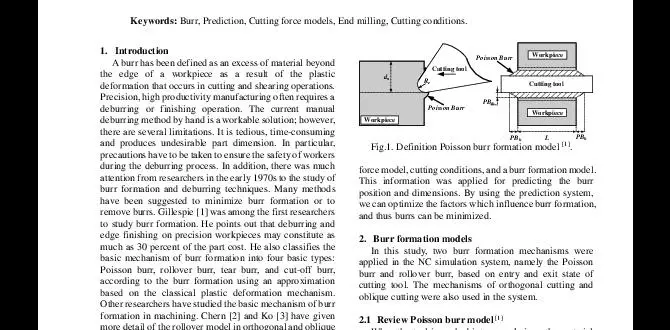

Definition and purpose of a collet system in a lathe.. Components of a collet system: collets, chuck, and more..A lathe collet system holds workpieces tightly while a lathe shapes them. It helps achieve precision in metalworking. The system has key parts, including:

- Collets: These are the main holders for different shapes and sizes of materials.

- Chuck: This part secures the collet in the lathe machine.

- Nut: This keeps the collet in place, ensuring the workpiece doesn’t slip.

Using a collet system allows for fast changes between different tasks. It’s essential for smooth operation and accuracy in metal lathe automation.

What are the advantages of a lathe collet system?

One main benefit is quick workpiece changes. This makes tasks faster and easier!

Key Points

- Versatility: Works well with various materials.

- Precision: Helps create accurate shapes.

- Safety: Reduces the risk of slipping during operation.

Advantages of Using Collet Systems in Metal Lathes

Enhanced precision and repeatability in machining.. Increased efficiency and reduced setup time for automated processes..Using collet systems in metal lathes can really turn the dial on precision and repeatability. With enhanced grip, they hold workpieces tightly, leading to perfect cuts every time. This means fewer mistakes and less wasted material—like cutting pizza slices instead of a whole pie! Plus, they cut setup time in half, making automated processes much faster. Who wouldn’t want to be as quick as a cat on a hot tin roof?

| Advantage | Description |

|---|---|

| Precision | Holds pieces tightly for accurate machining. |

| Efficiency | Reduces time spent on setup, speeding things along. |

Setting Up a Collet System for Automation

Stepbystep guide to installing a collet system on a metal lathe.. Tips for aligning and calibrating the system for optimal performance..Installing a collet system can improve your metal lathe’s automation. Here’s how to set it up:

- Gather all necessary tools and parts.

- Turn off the machine before starting.

- Remove the chuck from the spindle.

- Attach the collet closer to the spindle.

- Install the collet into the closer.

- Lock the collet in place.

- Check the alignment with a dial indicator.

For better performance, calibrate your system by adjusting the tension until it holds parts firmly. Regularly clean the collets to prevent stickiness.

What is the best way to align and calibrate a collet system?

Use a dial indicator and adjust the collet tension for a snug fit. Regularly check for wear and keep everything clean. This helps your lathe run smoothly!

Best Practices for Maintaining Your Lathe Collet System

Routine maintenance tasks to ensure longevity and performance.. Common issues and troubleshooting tips related to collet systems..Taking care of your lathe collet system can turn a headache into sweet dreams of smooth operations! Start with regular cleaning. Dust and chips love to sneak in, and we don’t want those pesky guys interfering with our work. Check the collet and spindle for wear and tear; they should be as smooth as your favorite ice cream! If you encounter issues, like a collet not gripping, don’t panic! Clean and lubricate may just do the trick. This routine can keep your lathe happy and running strong.

| Task | Tip |

|---|---|

| Daily Cleaning | Wipe down with a soft cloth. |

| Weekly Checks | Inspect for wear and tear. |

| Proper Lubrication | Use recommended oils sparingly. |

Cost Analysis of Implementing Collet Systems in Metal Lathe Automation

Breakdown of initial investment versus longterm savings.. Factors to consider when budgeting for a collet system installation..Investing in a collet system for a metal lathe can seem large at first. However, it often pays off over time. Here’s a quick look at costs:

- Initial costs: This includes equipment, installation, and training expenses.

- Long-term savings: Reduced labor costs and faster production boosts profits.

- Maintenance costs: Consider ongoing expenses for upkeep and repairs.

Budget carefully. Think about how each factor might affect your total expenses. The right choice today can save money later!

What are the main factors to consider for budgeting a collet system?

The key factors include initial investment, potential savings, machine compatibility, and ongoing maintenance costs.Understanding these factors helps in making wise decisions. Investing in a collet system can change the game for metal lathe automation!

Future Trends in Lathe Collet Systems and Automation

Emerging technologies and innovations in collet design and automation.. Predictions for the future of metal machining with automated collet systems..The future of lathe collet systems looks brighter than a new light bulb! Emerging technologies are shaking things up. We can expect more efficient collet designs that fit snugly without a hitch. Automation will take the wheel, allowing machines to work smarter, not harder. Picture this: machines that talk to each other, helping to reduce errors and boost productivity. Experts predict that in the next decade, automated collet systems will lead to faster production times and lower costs. Say goodbye to manual labor and hello to a shiny future!

| Predicted Trends | Impact on Metal Machining |

|---|---|

| Advanced Sensors | Improve accuracy |

| Smart Automation | Reduce downtime |

| Eco-friendly Materials | Lower waste |

Conclusion

In conclusion, a lathe collet system improves metal lathe automation by making tasks easier and faster. This system grips tools securely, allowing for precise cuts. You can streamline your projects and boost productivity. If you’re interested, explore more about collet systems and automation techniques online. Start experimenting to see how these tools can help you in your work!FAQs

What Are The Advantages Of Using A Collet System Over Traditional Chucks In Automated Metal Lathe Operations?Collets are better than traditional chucks because they hold parts more tightly. This helps prevent slipping while we work. Collets also change quickly, which saves time. They are great for different sizes of parts too. Overall, using collets makes our work faster and easier!

How Does The Integration Of A Collet Clamping Mechanism Enhance The Precision And Efficiency Of Cnc Lathe Machining?A collet clamping mechanism helps hold the workpiece tightly in place. This means it won’t move around while the machine is working. When the piece stays still, it cuts more accurately. We also finish the job faster because the collet is easy to use and change. This makes everything smoother and better!

What Types Of Materials Are Commonly Used For Lathe Collets, And How Do Their Properties Impact Performance In Automated Systems?Lathe collets are often made from metal like steel or aluminum. Steel is strong and lasts a long time. Aluminum is lighter and makes machines work faster. These materials help the collets grip tools tightly and move smoothly in automated systems. Good materials mean better performance!

How Can Automation Technology, Such As Robotic Arms Or Conveyor Systems, Be Effectively Incorporated With Collet Systems In Metal Lathes?You can use robotic arms to pick up metal pieces and place them in collet systems on lathes. Conveyor systems can move these pieces quickly to the right spot. This saves time and helps make more items. Together, they make machines work faster and better. We can create a smoother workflow in factories.

What Are The Best Practices For Maintaining And Calibrating Collet Systems To Ensure Optimal Performance In Metal Lathe Automation?To keep collet systems working well, you should clean them regularly. First, take off any dirt or debris. Then, check for wear and tear. Make sure everything fits tightly when you put it back. Lastly, test the system often to fix any problems early. This way, your metal lathe works better and lasts longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Over Traditional Chucks In Automated Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Collets are better than traditional chucks because they hold parts more tightly. This helps prevent slipping while we work. Collets also change quickly, which saves time. They are great for different sizes of parts too. Overall, using collets makes our work faster and easier!”}},{“@type”: “Question”,”name”: “How Does The Integration Of A Collet Clamping Mechanism Enhance The Precision And Efficiency Of Cnc Lathe Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet clamping mechanism helps hold the workpiece tightly in place. This means it won’t move around while the machine is working. When the piece stays still, it cuts more accurately. We also finish the job faster because the collet is easy to use and change. This makes everything smoother and better!”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Commonly Used For Lathe Collets, And How Do Their Properties Impact Performance In Automated Systems? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe collets are often made from metal like steel or aluminum. Steel is strong and lasts a long time. Aluminum is lighter and makes machines work faster. These materials help the collets grip tools tightly and move smoothly in automated systems. Good materials mean better performance!”}},{“@type”: “Question”,”name”: “How Can Automation Technology, Such As Robotic Arms Or Conveyor Systems, Be Effectively Incorporated With Collet Systems In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use robotic arms to pick up metal pieces and place them in collet systems on lathes. Conveyor systems can move these pieces quickly to the right spot. This saves time and helps make more items. Together, they make machines work faster and better. We can create a smoother workflow in factories.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining And Calibrating Collet Systems To Ensure Optimal Performance In Metal Lathe Automation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep collet systems working well, you should clean them regularly. First, take off any dirt or debris. Then, check for wear and tear. Make sure everything fits tightly when you put it back. Lastly, test the system often to fix any problems early. This way, your metal lathe works better and lasts longer!”}}]}