Have you ever wondered how metal gets shaped into beautiful tools or intricate parts? One of the secrets behind this process is the lathe collet system.

This amazing tool helps hold different materials tightly in place while the lathe does its magic. Imagine making a perfect screw or an exquisite piece of jewelry! Each piece you see may have started on a metal lathe.

The lathe collet system is a key part of this machine. It uses tight grips to make sure everything stays steady. But how does it work with different sizes and shapes?

To understand this, let’s take a closer look at how the belt drives the lathe. The belt helps connect parts smoothly, allowing the lathe to spin and cut. It’s like the engine of a car but for metalworking!

Join us as we explore the fascinating world of lathe collet systems and discover how they change the way we see metalworking. You might be surprised by what goes on behind the scenes!

Lathe Collet System: Enhance Your Metal Lathe Belt Efficiency

Lathe Collet System Metal Lathe Belt

Imagine working on metal projects with precision and ease. A lathe collet system helps you secure your workpieces firmly. This system is known for its accuracy and ability to hold various shapes. Did you know that using a belt drive on a metal lathe increases efficiency? The right belt helps control speeds for different tasks. Overall, learning about these tools can improve your skills and make metalworking more enjoyable!What is a Lathe Collet System?

Definition and purpose of collet systems in metal lathes. Types of collets and their specific applications.A lathe collet system is a tool used in metal lathes to hold workpieces tightly. It grips different shapes and sizes without slipping. This makes it perfect for precise tasks. Collets come in various types, including:

- Standard collets: Great for general use.

- Hex collets: Perfect for holding hexagonal shapes.

- STEP collets: Ideal for stepped workpieces.

Each type serves a special purpose, ensuring accurate and efficient machining. This helps workers create high-quality items with ease.

What are the benefits of using a lathe collet system?

Using a lathe collet system provides improved accuracy and faster setup times. This makes work easier and more efficient for everyone involved.

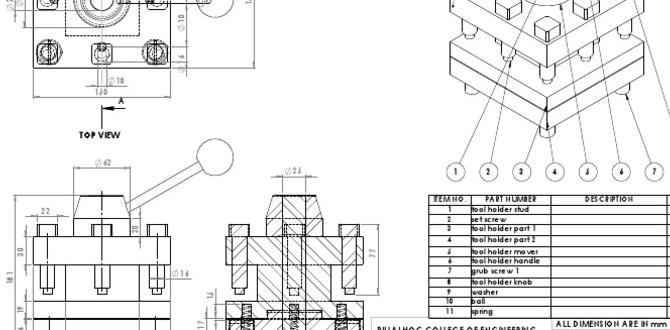

Components of a Lathe Collet System

Detailed description of key components: collets, chuck, and drawbar. Materials used in collet construction and their impact on performance.A lathe collet system is made up of key components. First, collets hold the workpiece tightly. They grip different shapes and sizes securely. Next is the chuck, which is the main part that keeps the collet in place. Lastly, the drawbar connects to the collet, helping to tighten or loosen it during work. Collets are often made from steel or aluminum. These materials affect how well they perform. Steel provides strength, while aluminum is lighter and easier to handle.

What materials are used in collet construction?

Collets can be made from steel or aluminum. Steel is strong, while aluminum is lightweight and easy to use.

- Collets ensure a secure grip.

- Chucks hold the collet firmly.

- Drawbars adjust tension easily.

Benefits of Using a Belt Drive with Lathe Collet Systems

Advantages of belt drives over direct drives in metal lathes. Impact on speed control and torque management.Using a belt drive with lathe collet systems offers great benefits for metal lathes. First, they provide better speed control. This means you can easily adjust how fast the lathe spins. Second, they manage torque well. This helps prevent damage and keeps tools safe. Belt drives are often quieter and last longer too. Here are some key advantages:

- Improved speed control

- Better torque management

- Durability and reliability

- Quieter operation

Why choose a belt drive over direct drive?

Belt drives allow for smoother operation and less wear on machines.

How to Choose the Right Collet for Your Metal Lathe

Factors to consider when selecting a collet type (size, type of workpiece). Common sizes and standards in the industry.Choosing the right collet for your metal lathe is important. First, consider the size of your workpiece. Collets must fit snugly for safety and precision. Next, think about the type of workpiece you will use. Different jobs may need different collets. Common collet sizes include:

- 1/8 inch

- 1/4 inch

- 1/2 inch

- 3/4 inch

- 1 inch

Each size works best for specific projects. Make sure to check industry standards for your needs.

What should I consider when choosing a collet?

Think about size and workpiece type. These factors ensure that your collet works well with your metal lathe.

Installation and Setup of Lathe Collet Systems

Stepbystep guide to installing a collet system on a beltdriven lathe. Common mistakes to avoid during setup.To set up a lathe collet system on a belt-driven lathe, follow these steps:

- Start by cleaning the lathe. Any dirt can cause problems.

- Remove the spindle faceplate carefully.

- Install the collet chuck on the spindle. Ensure it fits snugly.

- Secure the collet in place. Check for tightness.

- Reattach the faceplate. Make sure it’s secure.

- Test the setup with a low speed before working on projects.

Avoid these common mistakes:

- Don’t forget to clean before setup.

- Check that the collet fits your workpiece.

- Ensure everything is tight to prevent accidents.

What common mistakes should I avoid during setup?

Common mistakes include not cleaning the lathe, using the wrong collet size, and failing to secure parts tightly. Check connections often to ensure safety and efficiency.

Following these steps ensures proper installation. A good setup means better results and safer use. Remember, safety first!

Maintenance Tips for Lathe Collet Systems

Routine maintenance practices to ensure longevity and performance. Troubleshooting common issues with collets and belt drives.Taking care of your lathe collet system is key for smooth operation. Regular maintenance keeps your equipment running well. Here are some important tips:

- Check collets for dirt and damage.

- Clean the belt regularly to reduce wear.

- Inspect the belt tension. A loose belt can slip.

- Lubricate moving parts to prevent rust.

- Ensure proper alignment of components.

If you notice trouble, like odd noises or slipping, check the belts and collets. Fixing these issues quickly can save you time and money.

What should I do if my lathe collet system is not working?

First, check for any loose parts. Make sure everything is tight. Then, look for dirt or damage on your collets and belts. Cleaning and adjusting them often solves many problems.

Comparative Analysis of Collet Systems for Different Metal Lathes

Comparison of collet systems used in hobbyist vs. industrial lathes. Analysis of cost vs. performance in various collet types.Different metal lathes use different collet systems. Hobbyists often choose lighter systems for fun projects, while industrial lathes go for heavy-duty options. It’s like choosing between a toy car and a monster truck! In terms of cost, hobbyists spend less but might sacrifice a bit of performance. Compare that to industrial collets, which are pricey but perform like champions. Check out the table below for a quick comparison:

| Collet Type | Cost | Performance |

|---|---|---|

| Hobbyist | Low | Moderate |

| Industrial | High | Excellent |

So, which one is better? It depends on your needs! Remember, more money often means better performance. It’s like that saying: “You get what you pay for!”

Innovations in Lathe Collet Systems and Belt Drive Technology

Recent advancements and trends in the collet system market. Future possibilities for enhanced performance and usability.Recently, lathe collet systems have seen some nifty upgrades. New designs make swapping out collets quick and breezy, saving time on projects. Also, many lathes now boast better grip for precision work. Future tech promises even more cool features, like smart sensors that tell you when your collet needs a hug. Who knew a metal lathe could be so friendly? Here’s a peek at the latest trends:

| Innovation | Description |

|---|---|

| Quick Change Collets | Allows faster tool changes, so you can spend less time waiting and more time creating! |

| Enhanced Grip | Improves precision, making your projects more accurate than ever. |

| Smart Technology | Future models might even come with alerts for maintenance. Because nobody likes surprise repairs! |

With each step forward, metal lathes evolve into helpful partners in your workshop adventure. Your lathe might just start asking you how your day was!

Conclusion

In summary, a lathe collet system on a metal lathe helps you hold materials tightly and accurately. The belt drives the lathe, giving smooth power for better cuts. By learning how to use these tools, you can improve your metalworking skills. We encourage you to explore more about lathe systems to enhance your projects and creativity. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Lathe Collet Systems For Metal Lathes And Belt Mechanisms:Lathe collet systems hold things tightly while you work on metal lathes. They help make sure your pieces don’t move around. Belt mechanisms are like strong rubber bands that turn the lathe. They help the machine run smoothly and at the right speed. Together, these parts make working with metal easier and safer!

Sure! Just let me know what question you want me to answer, and I’ll be happy to help in simple words!

What Are The Advantages Of Using A Collet System In A Metal Lathe Compared To Traditional Chuck Systems?Using a collet system in a metal lathe has some cool benefits. First, it grips the metal piece better, so it won’t slip while you work. This helps you make smoother cuts. Second, collets can hold different sizes of pieces easily; you just change the collet. Lastly, they are usually lighter and easier to use than traditional chucks.

How Do You Choose The Appropriate Collet Size And Type For Specific Workpieces In A Lathe Operation?To choose the right collet, first measure the diameter of your workpiece. Collets hold shapes snugly, so pick one that matches your piece’s size. Check if you need a specific type, like a 3-jaw or a 4-jaw collet, depending on the shape of your workpiece. Always make sure the collet opens and closes easily. Finally, make sure the collet fits your lathe properly.

What Maintenance Practices Are Recommended For Ensuring Optimal Performance Of A Belt-Driven Lathe And Its Collet System?To keep a belt-driven lathe working well, you should regularly clean it. Dust and dirt can make it harder to work. Check the belts for any damage and replace them if needed. Make sure the collet system is tight and free of debris. Finally, oil the moving parts to help them run smoothly.

How Does The Tension Of The Drive Belt Affect The Performance And Precision Of A Metal Lathe Using A Collet System?The tension of the drive belt is very important for a metal lathe. If the belt is too loose, the lathe won’t spin right. This can make your work wobbly and not very accurate. A tight belt helps the lathe run smoothly, so we get better results. So, making sure the belt is just right helps us do a great job!

What Factors Should Be Considered When Upgrading Or Replacing The Collet System And Drive Belt On An Older Metal Lathe?When upgrading or replacing parts on an older metal lathe, you should think about a few things. First, check the size and fit of the new collet system. It needs to match your lathe to work correctly. Next, consider the type of drive belt. Make sure it’s the right style for your machine. Lastly, think about how often you use the lathe. If you use it a lot, newer parts can help it run better and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Collet Systems For Metal Lathes And Belt Mechanisms:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe collet systems hold things tightly while you work on metal lathes. They help make sure your pieces don’t move around. Belt mechanisms are like strong rubber bands that turn the lathe. They help the machine run smoothly and at the right speed. Together, these parts make working with metal easier and safer!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer, and I’ll be happy to help in simple words!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System In A Metal Lathe Compared To Traditional Chuck Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system in a metal lathe has some cool benefits. First, it grips the metal piece better, so it won’t slip while you work. This helps you make smoother cuts. Second, collets can hold different sizes of pieces easily; you just change the collet. Lastly, they are usually lighter and easier to use than traditional chucks.”}},{“@type”: “Question”,”name”: “How Do You Choose The Appropriate Collet Size And Type For Specific Workpieces In A Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right collet, first measure the diameter of your workpiece. Collets hold shapes snugly, so pick one that matches your piece’s size. Check if you need a specific type, like a 3-jaw or a 4-jaw collet, depending on the shape of your workpiece. Always make sure the collet opens and closes easily. Finally, make sure the collet fits your lathe properly.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended For Ensuring Optimal Performance Of A Belt-Driven Lathe And Its Collet System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a belt-driven lathe working well, you should regularly clean it. Dust and dirt can make it harder to work. Check the belts for any damage and replace them if needed. Make sure the collet system is tight and free of debris. Finally, oil the moving parts to help them run smoothly.”}},{“@type”: “Question”,”name”: “How Does The Tension Of The Drive Belt Affect The Performance And Precision Of A Metal Lathe Using A Collet System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tension of the drive belt is very important for a metal lathe. If the belt is too loose, the lathe won’t spin right. This can make your work wobbly and not very accurate. A tight belt helps the lathe run smoothly, so we get better results. So, making sure the belt is just right helps us do a great job!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Upgrading Or Replacing The Collet System And Drive Belt On An Older Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When upgrading or replacing parts on an older metal lathe, you should think about a few things. First, check the size and fit of the new collet system. It needs to match your lathe to work correctly. Next, consider the type of drive belt. Make sure it’s the right style for your machine. Lastly, think about how often you use the lathe. If you use it a lot, newer parts can help it run better and last longer.”}}]}