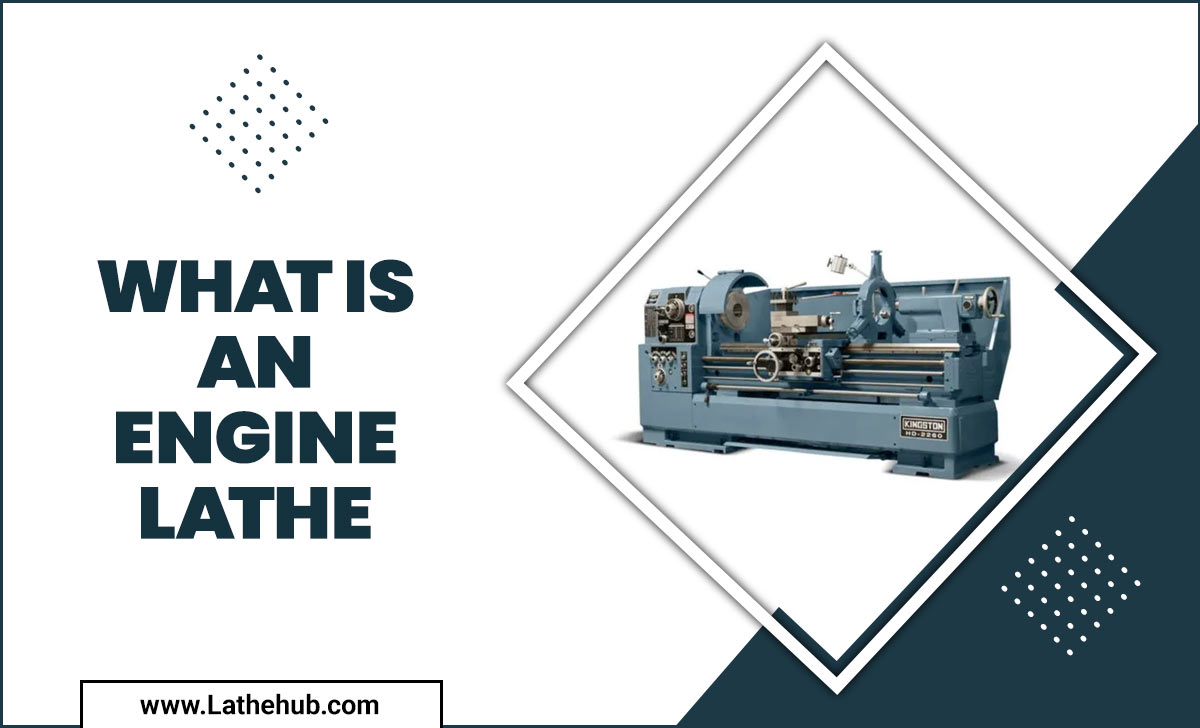

Have you ever wondered how metal pieces fit perfectly together? One secret lies in the lathe collet system. This tool works like a magic grip for shaping metal. It holds workpieces firmly while they spin, allowing for precision cuts.

But what about the lathe chuck key? This small but mighty tool makes changing collets easy. It’s like a key to a treasure chest, unlocking endless possibilities for metalwork!

Imagine crafting a beautiful piece of art or fixing a broken machine part. With the right tools, anyone can become a metalworking hero. The lathe collet system and chuck key are great starting points. They help you create quality work with less effort.

Curious to learn more? Let’s dive deeper into how these tools can transform your metalworking skills!

Lathe Collet System: Metal Lathe Chuck Key Explained

Understanding the Lathe Collet System

The lathe collet system is essential for metal lathes. It securely holds various workpieces, allowing for precise cuts. Have you ever struggled with a loose chuck? With a collet, that problem disappears. These systems offer quick changes, making them perfect for busy workshops. Did you know that using a collet instead of a chuck can improve accuracy? A lathe chuck key is a handy tool to tighten the collet tightly. This combination can elevate your metalworking projects significantly.What is a Lathe Collet System?

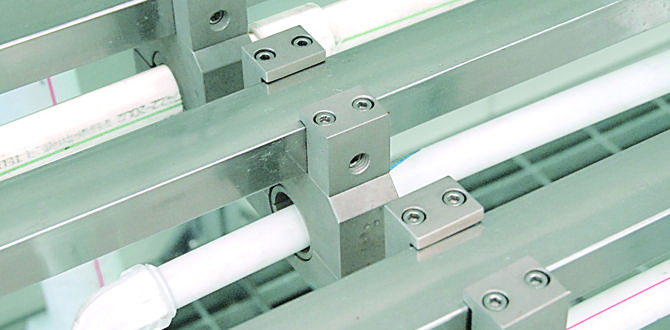

Definition and components of a lathe collet system. Importance in precision machining and metalworking.A lathe collet system plays a vital role in metalworking. It holds workpieces securely during machining. The system consists of a collet, a spindle, and a nut. The collet snugly grips the workpiece, preventing it from slipping. This is crucial for precision. Imagine trying to carve a turkey without holding it! A solid grip ensures accuracy and smooth finishes in your projects.

| Component | Function |

|---|---|

| Collet | Holds the workpiece tightly |

| Spindle | Connects to the lathe motor |

| Nut | Secures the collet in place |

This system is crucial for achieving precise cuts and maintaining safety while working. Think of it as a superhero team for your lathe! Each part works together to make sure your project doesn’t go haywire. Without it, you might end up with wobbly shapes or worse, flying objects!

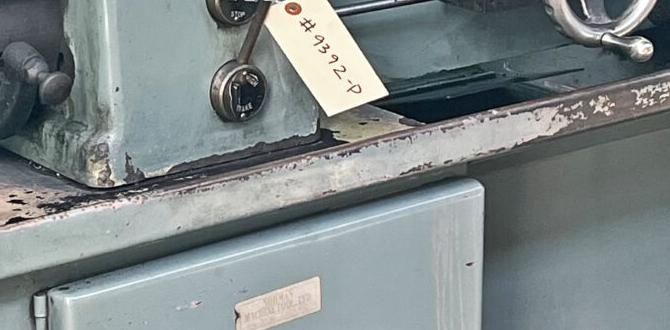

The Role of Chuck Keys in Metal Lathe Operations

Explanation of chuck keys and their function. Different types of chuck keys and their compatibility with lathe chucks.Chuck keys are essential tools in metal lathe operations. They help secure workpieces by tightening or loosening the lathe chuck. Without them, it can be hard to hold materials in place properly. There are different types of chuck keys, such as:

- Standard Chuck Keys: Fit most common chucks.

- Snap-on Chuck Keys: Designed for quick changes.

- Hex Key Chuck Keys: Used with hexagonal chucks.

It’s important to use the right chuck key for your specific lathe chuck. This ensures safety and efficiency during operations.

What is the function of a chuck key?

A chuck key tightens and loosens the lathe chuck, keeping materials secure during work.

Are there different types of chuck keys?

Yes, there are various types, including standard, snap-on, and hex key chuck keys.

How to Properly Use a Chuck Key

Stepbystep guide to using a chuck key safely and effectively. Common mistakes to avoid when operating a lathe with a chuck key.Using a chuck key safely is important for everyone working with a lathe. Follow these steps for effective use:

- Always check the chuck key before use.

- Insert the key firmly into the chuck.

- Turn the key slowly to tighten the chuck.

- Remove the key before starting the lathe.

- Never leave the key in the chuck while running.

Common mistakes include:

- Forgetting to remove the chuck key.

- Over-tightening the chuck, which can cause damage.

- Using a broken or worn-out chuck key.

By following these steps, you can use a chuck key effectively. Stay safe and enjoy your work!

What are the top safety tips for using a chuck key?

Always check the chuck key for damage, keep your hands clear while the lathe is running, and double-check that the key is removed before you start the machine.Quick Safety Tips:

- Wear safety goggles.

- Keep the area clean and clutter-free.

- Always follow the manufacturer’s instructions.

Maintenance Tips for Lathe Collet Systems and Chuck Keys

Importance of regular maintenance for optimal performance. Best practices for cleaning and storing collet systems and chuck keys.Keeping your lathe collet system and chuck keys in tip-top shape is key to smooth sailing. Regular maintenance boosts performance and saves you from hiccups. Think of it as giving your tools a spa day! Start by cleaning them with a gentle cloth after each use. Store them in a dry, safe place to avoid rust and damage. Here’s a quick table with tips:

| Action | Tips |

|---|---|

| Cleaning | Use a soft cloth and mild cleaner. |

| Storage | Keep them dry and in a case. |

| Inspection | Check for wear and tear regularly. |

Remember, a happy lathe results in happy projects. So, take care of those collets and keys, and they’ll reward you with smooth cuts and fewer surprises!

Choosing the Right Lathe Collet System for Your Needs

Factors to consider when selecting a lathe collet system. Comparisons of popular brands and models in the market.Picking a lathe collet system means considering a few key factors. First, think about the material you will work with. Different metals require different collets. Next, examine the size and capacity of the collet system to ensure it fits your lathe. Popular brands like Haas, Hardinge, and Sherline offer varying models. Check user reviews to see what others say. Ultimately, choose the system that meets your projects best.

What should I consider when choosing a lathe collet system?

Consider the material, size, and brand reputation. This will help you find the right match for your lathe.

Key factors include:

- Material Type

- Collet Size

- Brand Reviews

Knowing these points makes the selection easier and ensures successful projects!

Troubleshooting Common Issues with Lathe Collet Systems

Identifying typical problems (e.g., misalignment, wear and tear). Solutions and repairs for common issues.Lathe collet systems can face some common hiccups. One issue is misalignment, which makes your workpiece wobble like a dancer with two left feet. Another problem is wear and tear, which can sound like nails on a chalkboard if not fixed. To solve these, check alignment regularly. Tighten any loose parts and replace worn components. Remember, a happy lathe makes for a smoother project!

| Problem | Solution |

|---|---|

| Misalignment | Adjust and realign regularly. |

| Wear and Tear | Replace worn components immediately. |

Conclusion

In summary, a lathe collet system improves gripping for precision cutting. It offers better stability than traditional chucks. You can easily change tools, which saves time. If you’re working with a metal lathe, consider using a collet system for your projects. Explore online videos and tutorials to learn more and see it in action. Happy machining!FAQs

Sure! Here Are Five Questions Related To The Lathe Collet System And Metal Lathe Chuck Key:Sure! A lathe is a tool that spins metal to shape it. A collet is a part that holds the metal tightly. You use a chuck key to open and close the chuck, which is the part that holds the collet. This keeps everything safe while we work. It’s important to follow safety rules when using these tools!

Sure! Please tell me the question you want me to answer.

What Are The Advantages Of Using A Collet System Over A Traditional Chuck For Holding Workpieces On A Metal Lathe?Using a collet system is really useful for holding workpieces on a metal lathe. Collets grip tightly around the workpiece, which keeps it steady. This helps us make precise cuts. They also let you change pieces quickly and easily. Overall, collets help you work faster and more accurately than a traditional chuck.

How Do You Properly Install And Remove A Collet And Its Corresponding Collet Nut On A Metal Lathe?To install a collet on a metal lathe, first make sure the machine is off. Next, take the collet and slide it into the spindle. Then, screw the collet nut onto the collet until it is snug. To remove the collet, unscrew the collet nut first and then pull out the collet gently. Always remember to keep your hands safe and be careful while working!

What Factors Should Be Considered When Selecting The Appropriate Collet Size And Type For Different Materials And Diameters?When choosing a collet, think about the size of the material you’re using. It needs to fit snugly around what you’re holding. You also want to consider the type of material, like wood or metal, as different collets work better for each. Finally, check the diameter, or thickness, of your tool to make sure it matches the collet size.

What Is The Function Of A Chuck Key In A Metal Lathe, And How Do You Safely Use It To Tighten Or Loosen A Chuck?A chuck key is a special tool used with a metal lathe. It helps you tighten or loosen the chuck, which holds the metal piece. To use it safely, insert the key into the hole in the chuck. Turn it carefully to either tighten or loosen the grip on the metal. Always remember to remove the key when you finish, so it doesn’t get in the way!

How Can Improper Handling Of Collets And Chuck Keys Affect The Accuracy And Safety Of Machining Operations On A Lathe?If you don’t handle collets and chuck keys properly, it can mess up your work. The collet holds the tool in place, and if it’s loose, it can wobble. This wobbling makes your cuts uneven. Also, if a chuck key is left in, it can be dangerous and cause accidents. Always double-check that everything is tight and safe before you start.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Lathe Collet System And Metal Lathe Chuck Key:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that spins metal to shape it. A collet is a part that holds the metal tightly. You use a chuck key to open and close the chuck, which is the part that holds the collet. This keeps everything safe while we work. It’s important to follow safety rules when using these tools!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Over A Traditional Chuck For Holding Workpieces On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system is really useful for holding workpieces on a metal lathe. Collets grip tightly around the workpiece, which keeps it steady. This helps us make precise cuts. They also let you change pieces quickly and easily. Overall, collets help you work faster and more accurately than a traditional chuck.”}},{“@type”: “Question”,”name”: “How Do You Properly Install And Remove A Collet And Its Corresponding Collet Nut On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a collet on a metal lathe, first make sure the machine is off. Next, take the collet and slide it into the spindle. Then, screw the collet nut onto the collet until it is snug. To remove the collet, unscrew the collet nut first and then pull out the collet gently. Always remember to keep your hands safe and be careful while working!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting The Appropriate Collet Size And Type For Different Materials And Diameters?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a collet, think about the size of the material you’re using. It needs to fit snugly around what you’re holding. You also want to consider the type of material, like wood or metal, as different collets work better for each. Finally, check the diameter, or thickness, of your tool to make sure it matches the collet size.”}},{“@type”: “Question”,”name”: “What Is The Function Of A Chuck Key In A Metal Lathe, And How Do You Safely Use It To Tighten Or Loosen A Chuck?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A chuck key is a special tool used with a metal lathe. It helps you tighten or loosen the chuck, which holds the metal piece. To use it safely, insert the key into the hole in the chuck. Turn it carefully to either tighten or loosen the grip on the metal. Always remember to remove the key when you finish, so it doesn’t get in the way!”}},{“@type”: “Question”,”name”: “How Can Improper Handling Of Collets And Chuck Keys Affect The Accuracy And Safety Of Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t handle collets and chuck keys properly, it can mess up your work. The collet holds the tool in place, and if it’s loose, it can wobble. This wobbling makes your cuts uneven. Also, if a chuck key is left in, it can be dangerous and cause accidents. Always double-check that everything is tight and safe before you start.”}}]}