Have you ever wondered how metal parts are made? A lathe is a special tool that shapes metal into useful items. One key feature of a lathe is its collet system. This system holds the metal piece tightly in place. But why is that so important?

Imagine trying to carve a block of wood while it keeps slipping away. Frustrating, right? This is why a strong drive system matters in metal lathes. It helps the lathe spin smoothly and precisely. Without this, workers would have a tough time creating parts accurately.

Did you know that using a collet system can make setups quicker? This means less time worrying and more time crafting. Metalworkers love these systems for their ease and efficiency. They can create everything from small gears to large machine parts.

In this article, we’ll dive deeper into the lathe collet system and its drive mechanism. You’ll learn how these systems work together to make metalworking easier and more fun!

Lathe Collet System: Essential For Metal Lathe Drive System

Lathe Collet System and Metal Lathe Drive Systems

The lathe collet system holds tools tightly and securely during work. Imagine your favorite toy spinning smoothly without its parts falling apart. That’s what a collet does! It reduces vibrations for better precision and quality. The drive system powers the lathe, allowing it to rotate and shape metal. Did you know that many professionals prefer this setup for creating everything from small parts to big machines? Understanding these systems can help you create truly amazing projects!What is a Lathe Collet System?

Definition and purpose of a collet system in metalworking.. Comparison between collet systems and other workholding methods..A lathe collet system is a tool used in metalworking. It holds a workpiece snugly. This system is different from other methods, like chucks. Chucks can slip, while collets grip tightly. They fit different shapes and sizes of materials. This makes them great for precision work. Here are some benefits of a collet system:

- Better grip

- Faster setup

- Less vibration

Overall, the collet system is favored for its speed and accuracy in many metalworking tasks.

What are the advantages of a lathe collet system?

The collet system provides precision and quick changes. It can hold different sizes of workpieces securely. This makes it easy to switch between tasks.

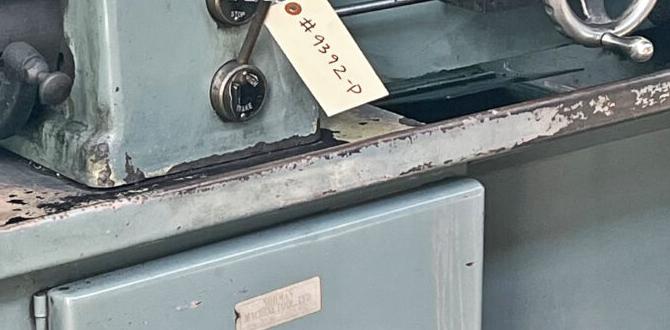

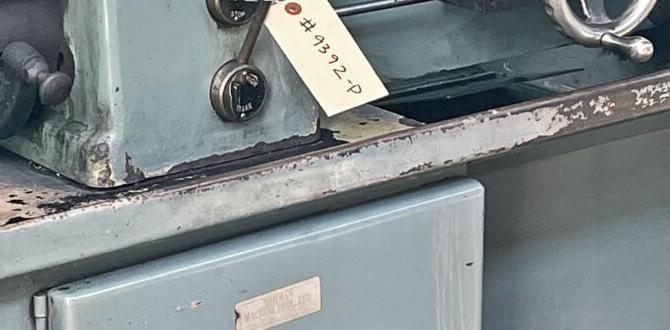

Components of a Lathe Collet System

Detailed description of key components (collets, jaws, nut).. Explanation of materials used in manufacturing collets..A lathe collet system has important parts that help it work. Key components include:

- Collets: These are metal devices that hold the workpiece tightly in place.

- Jaws: Jaws assist in gripping different shapes and sizes of materials.

- Nut: The nut secures the collet and maintains its grip.

Most collets are made from strong metals like steel or aluminum. Steel is durable and can handle heavy loads. Aluminum is lighter and resists rust. This choice helps make each component reliable in a metal lathe drive system.

What are the main features of a collet system?

The main features include easy setup, quick changes, and strong gripping power. These features make collet systems very useful in many projects.

Benefits of Using a Collet System

Enhanced precision and accuracy in machining processes.. Increased workholding flexibility for various workpiece shapes..Using a collet system can make machining as easy as pie. It allows for enhanced precision, which means your cuts are sharp and exact, unlike that one time you tried to cut a bang on your own. With a collet, the workpiece fits snugly and won’t wiggle around like jelly on a plate. Plus, the system offers increased flexibility for holding different shapes, whether round or square. This adaptability lets you create anything from simple screws to fancy art pieces without breaking a sweat.

| Benefit | Description |

|---|---|

| Precision | Sharp cuts for better quality work. |

| Flexibility | Holds various shapes, making it super handy. |

Setup and Operation of a Lathe Collet System

Stepbystep guide to installing a collet system on a metal lathe.. Best practices for effective operation and maintenance..Installing a collet system on your metal lathe can be simple and effective. Follow these steps:

- Gather your tools: collet chuck, collets, and wrenches.

- Unplug the lathe for safety. Remove the old chuck.

- Set the collet chuck in place and secure it tightly.

- Insert the desired collet and adjust to fit your workpiece.

- Plugin and test the lathe with a small piece of material.

For smooth operation and lasting use, keep these tips in mind:

- Always clean the collet and chuck before use.

- Never overtighten the collet on your workpiece.

- Regularly inspect for wear and tear.

What is a collet system in a metal lathe?

A collet system securely holds workpieces. It allows easy changes for different sizes. Using a collet system improves precision and efficiency in your projects.

Running a collet system correctly means less hassle. Enjoy cleaner cuts and faster setups!

Common Issues and Troubleshooting

Typical problems encountered with collet systems.. Solutions and preventive measures to ensure longevity and performance..Collet systems can have hiccups, but don’t fret! Common problems include inconsistent gripping or the collet getting stuck. These issues can make your workspace feel like a circus, but fear not! Regular cleaning and lubrication can ensure smoother operations. Preventative measures like checking for wear and tear can help too. Keep a lookout for loose fittings—those can cause major trouble! Try these solutions to keep your lathe performing well and maybe crack a smile while you’re at it!

| Problem | Solution | Prevention |

|---|---|---|

| Inconsistent Gripping | Check for dirt and clean collets. | Regular maintenance is key! |

| Collet Sticking | Try a little lubrication. | Store properly when not in use. |

| Loose Fittings | Tighten all connections. | Inspect before each use. |

Comparative Analysis: Collet System vs. Chuck System

Key differences in functionality and application between collets and chucks.. Situations where one may be preferred over the other..Collets and chucks are both handy tools in metalworking, but they have their unique traits. Collets hold small items tightly, like a secret handshake, ensuring precision. They excel in jobs needing exact fits, making them perfect for tiny screws or delicate parts. On the other hand, chucks are like the big friends at the party. They can hold larger materials and are simpler to use. If you’re working on something hefty, a chuck might be your go-to. Below is a quick comparison:

| Feature | Collet System | Chuck System |

|---|---|---|

| Size Range | Small items | Large items |

| Precision | High | Medium |

| Ease of Use | Moderate | Easy |

Choose wisely! For tiny tasks, grab a collet. For bigger jobs, let the chuck take charge! Remember, it’s all about finding the right tool for the right job, like knowing whether to wear sneakers or boots!

Conclusion

In conclusion, a lathe collet system improves precision and stability in metal lathes. It securely holds workpieces for accurate cutting. Understanding how this drive system works can enhance your metalworking skills. We encourage you to explore more about lathe systems and practice using one. You’ll create better projects and gain confidence in your craftsmanship!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Collet System And Metal Lathe Drive Systems:Sure! A lathe is a machine that spins things round to cut or shape them. A collet is a tool that holds other tools or pieces tightly. This makes sure they don’t move while we work. Drive systems help the lathe spin and do its job. It’s like the engine of a car, making everything go!

Sure! Please provide the question you would like me to answer.

What Are The Advantages Of Using A Collet System Over A Traditional Chuck In A Metal Lathe?A collet system holds parts tightly and evenly. This helps when you want to make very precise cuts. Collets are easier to change than traditional chucks, so you save time. They also fit different shapes better, giving you more choices. Overall, using a collet can make your work better and faster!

How Does The Precision Of A Lathe Collet System Impact The Overall Accuracy Of Machining Operations?The precision of a lathe collet system makes a big difference in how well we can machine parts. When the collet holds a piece tightly and correctly, the machine cuts more accurately. If it’s not precise, the cuts can be off, leading to mistakes. So, better precision means better results and less waste. Overall, it helps us make things that fit perfectly together.

What Factors Should Be Considered When Selecting A Collet Type For A Specific Application In Metalworking?When choosing a collet type for metalworking, think about what you need it for. First, consider the size of the tool you will use. Next, check the material. Some are better for soft metals, while others work well with hard metals. Finally, make sure it fits your machine correctly. This way, you can work safely and efficiently.

How Does The Drive System Of A Metal Lathe Influence Its Torque And Speed Capabilities During Machining?The drive system of a metal lathe helps control how fast or slow it spins. More power in this system means more torque, which helps cut through hard metal. If you want to go faster, the drive system can adjust the speed, but it might need to use less force. So, a good drive system lets you choose the right speed and strength for different jobs.

What Maintenance Practices Are Essential For Ensuring Optimal Performance Of Both Collet Systems And Drive Systems In A Lathe?To keep your lathe working well, you should do a few key things. First, regularly clean the collet system and remove any debris. Next, check the drive system’s belts and gears for wear and replace them if needed. Lubricate moving parts to help them move smoothly. Lastly, make sure all screws and bolts are tight to avoid any problems while you work.