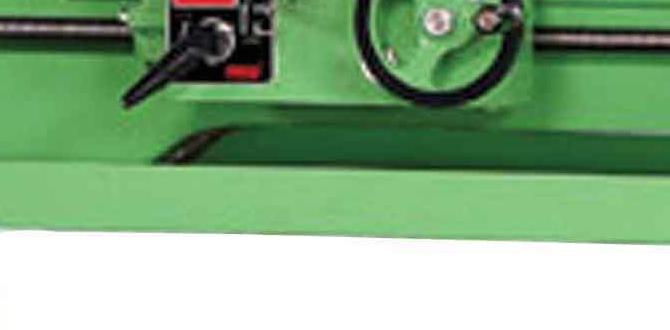

Have you ever wondered how a piece of metal turns into a perfect shape? The magic often lies in a machine called a lathe. A lathe lets us shape metal with precision. But what’s the secret behind this clever tool? It’s all about the lathe collet system and the gear train that helps it work smoothly.

Think of it this way: if you had a friend who always knew exactly how to hold your toy just right, you could make it spin better. That’s similar to what a lathe collet system does. It holds the metal piece tight so it doesn’t wiggle while the lathe spins it around. Without this system, creating neat shapes would be tricky.

Now, imagine a toy train that moves faster when you connect its cars. That’s how a gear train in a lathe works. It helps change the speed and power of the machine, letting you control how fast or slow the metal is shaped. Isn’t it cool how these simple ideas come together to create something so useful?

In this article, we will explore the fascinating world of metal lathes. We will uncover how the lathe collet system and gear trains function. Get ready to discover the secrets behind shaping metal like a pro!

Lathe Collet System: Understanding Metal Lathe Gear Train

Lathe Collet System in Metal Lathes

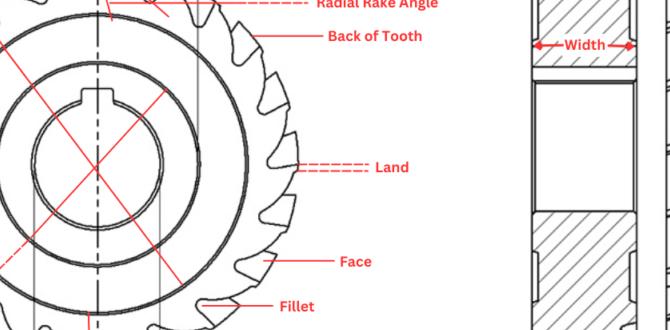

Have you ever wondered how metal lathes hold tools securely? The lathe collet system is the answer. It grips tools tightly, ensuring precision cutting. This system is efficient and easy to use, making tasks more straightforward for hobbyists and professionals alike. Another critical aspect is the gear train. It helps control speed and power in the lathe. Understanding these elements can improve your skills and projects. Did you know that a well-optimized lathe can create intricate designs that seem almost magical?What is a Lathe Collet System?

Definition and purpose of a lathe collet system. Advantages of using collets over other holding methods.A lathe collet system is a special tool that holds and grips various items securely while they are being shaped or cut. Think of it as a gentle but firm hug for your workpiece! Using collets offers some perks. They provide better grip and precision compared to other methods like chucks. Plus, they let you change tools quickly, which means you can spend more time making cool stuff and less time fiddling around. It’s like having a magic wand for your metalworking! Here’s a quick look at the differences:

| Method | Grip Strength | Speed of Change |

|---|---|---|

| Collet | Strong | Fast |

| Chuck | Moderate | Slow |

So, if you want to make your projects easier and more precise, a collet system is the way to go!

How to Choose the Right Collet for Your Project

Factors to consider when selecting a collet (e.g., size, material). Tips for matching collets to specific workpieces.Choosing the right collet for your project is essential for success. Here are some key factors to consider:

- Size: Match the collet size to your workpiece for a snug fit.

- Material: Select a durable material that suits your project needs.

For example, metal collets work well with most metals, while plastic is better for softer materials. Properly matching collets ensures cleaner cuts and smoother finishes. Don’t overlook these details—they can make or break your project!

What factors should I consider when choosing a collet?

When selecting a collet, focus on size and material. Size ensures a perfect fit while the right material affects performance. Each choice can greatly impact your results.

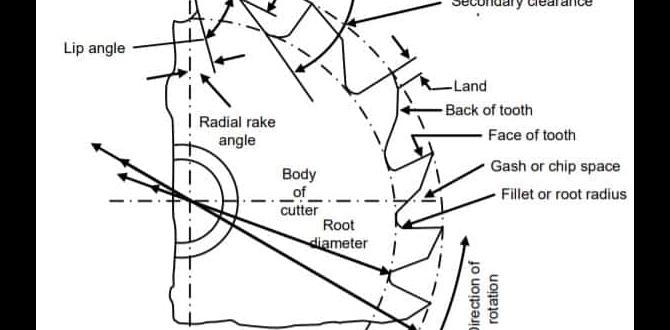

How Gear Trains Affect Lathe Performance

Impact of gear ratios on speed and torque. Importance of gear train maintenance for optimal performance.Gear trains play a big role in how a lathe works. They influence speed and torque, which are crucial for shaping metal. The gear ratio decides how fast the lathe spins and how much power it has. A higher ratio means better speed, while a lower ratio boosts torque.

Keeping your gear train in good shape is vital for the lathe’s performance. Regular maintenance ensures smooth operation. Here are some tips:

- Check for wear and tear.

- Oil the moving parts.

- Replace damaged gears promptly.

What should I check in my lathe’s gear train?

Look for worn gears, strange noises, or any dirt buildup. Keeping everything clean helps your lathe run better.

Setting Up and Adjusting Your Lathe Collet System

Stepbystep guide to installing collets on a lathe. Tips for adjusting the collet system for precision work.Installing collets on your lathe is easy with a few simple steps. First, clean the spindle area well. Then, select the right collet size for your workpiece. Next, slide the collet into the spindle and secure it tightly. Don’t forget to check for proper alignment. For precision work, adjust the collet tension carefully. A well-adjusted collet ensures better results.

How do I make adjustments for better precision?

Adjust the collet system by gently turning the tension knob. Test it with a scrap piece of material. Keep tweaking until the fit feels just right.

Common Issues and Troubleshooting in Collet Systems and Gear Trains

Typical problems faced with collet systems and their solutions. Gear train issues and how to address them effectively.Collet systems can be tricky sometimes. A common hiccup is the collet not gripping. This can happen if dirt sneaks in or the collet wears out. The fix? Clean it well or swap it for a fresh one! Gear trains have their own quirks, like skipping or loud noise. This often means gears are misaligned or need lubrication. The solution is simple: Align the gears and keep them greased! Keep your tools happy, and they’ll work for you!

| Issue | Solution |

|---|---|

| Collet Not Gripping | Clean or replace the collet. |

| Gear Train Skipping | Align gears and apply lubricant. |

| Loud Gear Noise | Check for wear and looseness. |

Maintenance Tips for Collet Systems and Gear Trains

Best practices for cleaning and maintaining collets. Recommended maintenance schedule for gear trains to ensure longevity.To keep your collet systems and gear trains happy, clean them regularly. Use a soft cloth to wipe off any dirt or grime. This simple step can make them last longer. For gear trains, stick to a maintenance schedule. Check them every month, and don’t forget to add some oil. A well-oiled gear is a happy gear! After all, gears need love too!

| Task | Frequency |

|---|---|

| Clean collets | Monthly |

| Inspect gear trains | Every month |

| Oil gears | Monthly |

Remember, when you take care of your tools, they take care of you!

Real-World Applications of Lathe Collet Systems and Gear Trains

Case studies highlighting successful projects using collet systems. Examples of industries that rely heavily on these components.Many companies use lathe collet systems and gear trains for important work. One example comes from the automotive industry. They use these systems to make precise parts for cars. A famous car maker improved production speed by 30% by switching to collet systems. Other industries also rely on these tools:

- Aerospace

- Manufacturing

- Metalworking

These fields need high accuracy. Collet systems help ensure that every piece is made correctly. Gear trains boost the machine’s speed and efficiency. This combination helps save time and resources.

What industries use collet systems?

Aerospace, manufacturing, and metalworking regularly rely on collet systems for precise production and enhanced speed.

Conclusion

In summary, a lathe collet system helps hold workpieces tightly on a metal lathe. The gear train allows for smooth movement and precise cutting. You can create better projects by understanding these tools. Explore manuals or videos on how to use them effectively. With practice, you’ll improve your skills and enjoy working with lathes even more!FAQs

What Is The Primary Function Of A Collet System In A Metal Lathe, And How Does It Differ From Using Traditional Chucks?A collet system helps hold small metal pieces tightly in a metal lathe. This keeps them stable while you work on them. Collets make it easier to change pieces quickly. Traditional chucks can hold bigger pieces but may not hold smaller ones as securely. So, collets are great for small jobs, while chucks are better for larger ones.

How Do Different Sizes And Types Of Collets Affect The Precision And Efficiency Of Machining Operations On A Lathe?Different sizes and types of collets hold tools or materials in place on a lathe. When we use the right collet, it can help us make precise cuts and shapes. If the collet is too big or too small, it can cause mistakes. Also, some collets work better with certain materials, making our work faster and easier. Using the right collet helps you do a better job!

Can You Explain The Role Of The Gear Train In A Metal Lathe And How It Influences Spindle Speed And Torque During Machining?The gear train in a metal lathe helps turn the spindle, which is the part that holds the metal piece. It can change how fast the spindle spins, which we call spindle speed. When you adjust the gears, you can also change the force, or torque, that helps cut the metal. This means you can make the lathe work better depending on what you’re making. Gears make it easier to control both speed and power while machining.

What Are The Benefits Of Utilizing A Collet System In Production Work Compared To Conventional Clamping Methods?Using a collet system in production work is really helpful. First, it holds tools tightly, so they don’t slip. This makes for better cuts and smoother work. Second, it’s easy to change tools quickly, saving you time. Lastly, collet systems work with different sizes, giving you more choices.

How Do You Determine The Appropriate Gear Ratios Within A Lathe’S Gear Train For Specific Machining Tasks Or Material Types?To choose the right gear ratios in a lathe, we think about what we are making. If we want to cut hard metal, we need slower speeds and stronger power. For softer materials, like wood, we can use faster speeds. We also look at the size of the part we’re working on. Balancing speed and power helps us get the best results for each task.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Primary Function Of A Collet System In A Metal Lathe, And How Does It Differ From Using Traditional Chucks? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet system helps hold small metal pieces tightly in a metal lathe. This keeps them stable while you work on them. Collets make it easier to change pieces quickly. Traditional chucks can hold bigger pieces but may not hold smaller ones as securely. So, collets are great for small jobs, while chucks are better for larger ones.”}},{“@type”: “Question”,”name”: “How Do Different Sizes And Types Of Collets Affect The Precision And Efficiency Of Machining Operations On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different sizes and types of collets hold tools or materials in place on a lathe. When we use the right collet, it can help us make precise cuts and shapes. If the collet is too big or too small, it can cause mistakes. Also, some collets work better with certain materials, making our work faster and easier. Using the right collet helps you do a better job!”}},{“@type”: “Question”,”name”: “Can You Explain The Role Of The Gear Train In A Metal Lathe And How It Influences Spindle Speed And Torque During Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear train in a metal lathe helps turn the spindle, which is the part that holds the metal piece. It can change how fast the spindle spins, which we call spindle speed. When you adjust the gears, you can also change the force, or torque, that helps cut the metal. This means you can make the lathe work better depending on what you’re making. Gears make it easier to control both speed and power while machining.”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Utilizing A Collet System In Production Work Compared To Conventional Clamping Methods? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system in production work is really helpful. First, it holds tools tightly, so they don’t slip. This makes for better cuts and smoother work. Second, it’s easy to change tools quickly, saving you time. Lastly, collet systems work with different sizes, giving you more choices.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Gear Ratios Within A Lathe’S Gear Train For Specific Machining Tasks Or Material Types? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right gear ratios in a lathe, we think about what we are making. If we want to cut hard metal, we need slower speeds and stronger power. For softer materials, like wood, we can use faster speeds. We also look at the size of the part we’re working on. Balancing speed and power helps us get the best results for each task.”}}]}