Have you ever wondered how metal parts are shaped perfectly? A lathe collet system might hold the secret. This handy tool works with a metal lathe to grip and spin materials. With this system, you can create precise shapes, whether it’s a small gadget or a large gear.

Many people don’t realize how important the lead screw is in this process. It helps move the cutting tool smoothly along the material. Imagine trying to draw a straight line while shaking your hand. It wouldn’t work very well! The lead screw keeps everything steady and accurate.

Did you know that using a lathe can be a creative adventure? Makers use lathes to craft beautiful objects from wood or metal. With the right tools, anyone can start their journey into the world of machining. Why not explore the magic of lathe collet systems and discover the artistry of metal turning?

Understanding The Lathe Collet System And Metal Lathe Lead Screw

Understanding the Lathe Collet System and Lead Screw

The lathe collet system is essential for securely holding workpieces in metal lathes. This system allows for quick changes and precise gripping, making metalworking easier. Ever wondered how a lead screw works? It’s the driving force behind the lathe, ensuring smooth movement. Without it, your projects could go off track. Using both tools effectively can enhance your machining skills. Did you know that even small adjustments can lead to big improvements?What is a Lathe Collet System?

Definition and purpose of a collet system in lathes. Types of collets commonly used in metalworking.A lathe collet system holds workpieces firmly while the lathe does its magic. Think of collets like a friendly bear hug for your metal! They keep things in place while cutting and shaping. Common types include the ER collet, which is like the Swiss army knife of collets, and the 3-Jaw chuck, known for its easy grip on different shapes. Using the right collet helps you create precise and smooth parts. Here’s a quick look at some popular collet types:

| Collet Type | Description |

|---|---|

| ER Collet | Versatile, used for various sizes. |

| 3-Jaw Chuck | Great for round and irregular shapes. |

| Boring Collet | Specialized for boring tasks. |

Understanding these collets can help you be a metalworking superstar!

Benefits of Using a Collet System

Advantages over traditional chuck systems. Increased precision and repeatability in machining.Swapping to a collet system brings perks that your old chuck system can’t match. First, it grips your workpiece more evenly, making it as snug as your favorite hoodie. This snugness means increased precision in machining. You’ll find that tiny details come out just right, saving you time and material! Plus, you can repeat the process over and over without worrying. It’s like having a magic spell for flawless work! Take a look at this quick comparison:

| Feature | Traditional Chuck | Collet System |

|---|---|---|

| Grip Stability | Good | Excellent |

| Precision | Moderate | High |

| Setup Time | Longer | Shorter |

So, if you want to make your lathe work smarter and faster, consider the collet system—a little upgrade with a big impact!

Understanding Metal Lathe Lead Screws

Definition and function of lead screws in metal lathes. Comparison of lead screws with other drive systems.Lead screws are crucial parts of a metal lathe. They help turn the machine’s movements into precise actions. Think of them as the muscles of the lathe. While they move the cutting tool back and forth, other systems might struggle. Comparing lead screws to gears, the screws offer smoother movements. Gears can be noisy and jerky—like a cat stuck in a tree! Below is a quick comparison of lead screws and other drive systems:

| Feature | Lead Screw | Gear System |

|---|---|---|

| Smooth Operation | Yes | Nope! |

| Noise Level | Quiet | Loud like a rock band |

| Precision | High | Depends on the gear teeth |

In short, lead screws are often a better choice for metal lathes. They promise smooth and accurate cutting action, making every project feel like a home run instead of a swing and miss!

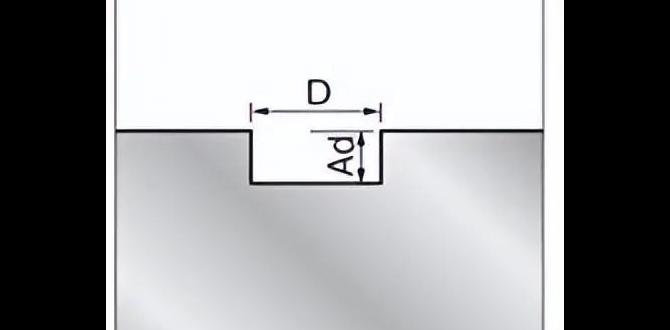

Operational Mechanism of Lead Screws

Breakdown of how lead screws facilitate movement in machining. Importance of lead screw pitch and its effect on machining speed.Lead screws play a key role in moving parts smoothly and precisely in machining. They work like a twisty path, turning rotational motion into linear motion. Think of them as the conveyor belt of a snack factory but without the snacks! The pitch of the lead screw, which is the distance between threads, is super important. A fine pitch means slower movement but better control, while a coarse pitch means faster movement but less precision. It’s like choosing between a lazy river and a thrilling roller coaster!

| Lead Screw Pitch | Machining Speed | Control Level |

|---|---|---|

| Fine | Slow | High |

| Coarse | Fast | Lower |

Choosing the Right Collet System for Your Metal Lathe

Factors to consider when selecting a collet system. Compatibility with various lathe models.Choosing the right collet system is important for your metal lathe. First, consider the size of your projects. The collet needs to hold your work securely. Next, check if it fits your lathe model. Not all collets are the same. Look also for ease of use. A simple system may be better for beginners. Finally, think about the materials you’ll work with. Some collets work better with metal than others.

What should I consider when selecting a collet system?

Key factors include size, compatibility with your lathe model, ease of use, and material type.Factors to Consider:

- Size of projects

- Lathe model compatibility

- Ease of use

- Material type

Maintenance Tips for Collet Systems and Lead Screws

Best practices for maintaining collet systems. How to care for and adjust lead screws for optimal performance.Taking care of your collet systems is like giving your metal lathe a spa day. Clean them regularly to keep them happy and rust-free. Use a soft cloth to wipe away the gunk. For lead screws, check for wear and tear often. They need love too! Lubricate them to ensure smooth movement. Remember: If your lead screw is squeaking, it’s not singing a happy tune!

| Task | Frequency |

|---|---|

| Clean collets | Weekly |

| Inspect lead screws | Monthly |

| Lubricate lead screws | Every 3 Months |

Your lathe will perform better when you take these simple steps. After all, a happy lathe means happy projects!

Common Issues and Troubleshooting

Typical problems encountered with collet systems. Diagnosing lead screw issues and potential solutions.Collet systems sometimes act like a cat on a hot tin roof—full of surprises! A common issue is slippage, where the workpiece doesn’t grip well, turning your precision work into a wobbly mess. Check for dirt or debris in the collet; a quick clean often does the trick!

Lead screws can also throw a tantrum, causing misalignment. Listen for odd sounds—if they’re too loud, it’s time to diagnose! Tighten any loose parts or apply oil for smooth operation. Remember, a little care goes a long way in keeping your lathe in shape!

| Problem | Possible Cause | Solution |

|---|---|---|

| Slippage in collet | Dirt in the collet | Clean the collet |

| Lead screw misalignment | Loose parts | Tighten and oil |

Applications of Collet Systems and Lead Screws in Metalworking

Specific industries that benefit from these systems. Examples of projects best suited for collet systems and lead screws.Many industries use collet systems and lead screws for better precision. These tools are great for factories that make machines and parts. They help cut metal more accurately. Some examples of projects include:

- Making gears and shafts.

- Creating custom tools.

- Building parts for cars and airplanes.

These systems improve speed and accuracy. This makes them important for manufacturers in various fields.

What industries benefit from collet systems and lead screws?

Industries like automotive, aerospace, and machinery rely on these systems for precise metalworking.

The Future of Lathe Technology

Innovations in collet systems and lead screws. Predictions for advancements in lathe machining technology.New ideas are changing lathe technology. Collet systems are getting better. They hold tools firmly, which helps with accuracy. Lead screws are also improving. They now offer smoother movement and less friction. These changes make lathes faster and more efficient. In the future, we may see machines that learn from their environment. They could adjust themselves for better performance.

What innovations should we expect in lathe technology?

We can expect new features in lathe technology, such as:

- Smart controls that change settings automatically.

- More energy-efficient designs that save power.

- Improved materials for long-lasting parts.

Conclusion

In conclusion, a lathe collet system is essential for holding metal workpieces securely. Learning about the lead screw helps you understand how to control movement accurately. By mastering these tools, you can improve your skills significantly. Try experimenting with different setups on your lathe. For more information, check out guides or videos on lathe operations to enhance your knowledge!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems, Metal Lathes, And Lead Screws:Sure! A lathe is a machine that helps us shape metal into different forms. The collet system holds the metal tightly so we can work on it safely. A lead screw is like a long, turning rod that helps move the tool back and forth. Together, these parts let us create neat designs and shapes from metal. It’s fun to see how they work!

Sure! Please ask your question, and I’ll be happy to help you with the answer.

What Are The Advantages Of Using A Collet System Compared To Traditional Chucks In A Metal Lathe?Using a collet system on a metal lathe has several advantages. First, it holds your metal piece tighter, which means less wobbling. Second, it can work with different sizes quickly and easily. Also, collets are usually lighter than traditional chucks, making them easier to handle. This helps you make better shapes and cuts in your projects.

How Does The Lead Screw Mechanism In A Metal Lathe Contribute To Precision And Accuracy During Machining?The lead screw in a metal lathe helps move the cutting tool smoothly. It does this by turning a long screw that pushes the tool back and forth. When you turn the screw, it moves the tool exactly where you want it. This makes the cuts sharp and neat. With the lead screw, your work is more accurate and precise.

What Types Of Materials Are Commonly Used For Manufacturing Collets, And How Do They Impact The Performance Of The Collet System?Collets are often made from metal like steel or aluminum. Steel is strong and lasts a long time. Aluminum is lighter, making it easier to handle. The material affects how tightly the collet holds tools, which helps keep things safe while working. Better materials mean better performance!

Can A Lead Screw Be Upgraded Or Replaced In An Existing Metal Lathe To Improve Its Functionality, And If So, What Considerations Should Be Taken Into Account?Yes, you can upgrade or replace a lead screw in a metal lathe. This can help it work better and more smoothly. First, you need to check the size and type of the new lead screw. You should also ensure it fits well with the machine. Finally, consider how much money and time you can spend on this upgrade.

How Do Collet Sizes And Types Affect The Versatility And Usability Of A Metal Lathe For Various Machining Tasks?Collet sizes and types help hold different tools or materials tightly on a metal lathe. When you change collets, you can work with larger or smaller pieces. This makes your lathe more flexible for various jobs. Using the right collet lets you do more types of work easily and accurately. So, having different collets means you can be more creative in what you make!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems, Metal Lathes, And Lead Screws:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal into different forms. The collet system holds the metal tightly so we can work on it safely. A lead screw is like a long, turning rod that helps move the tool back and forth. Together, these parts let us create neat designs and shapes from metal. It’s fun to see how they work!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you with the answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Compared To Traditional Chucks In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system on a metal lathe has several advantages. First, it holds your metal piece tighter, which means less wobbling. Second, it can work with different sizes quickly and easily. Also, collets are usually lighter than traditional chucks, making them easier to handle. This helps you make better shapes and cuts in your projects.”}},{“@type”: “Question”,”name”: “How Does The Lead Screw Mechanism In A Metal Lathe Contribute To Precision And Accuracy During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lead screw in a metal lathe helps move the cutting tool smoothly. It does this by turning a long screw that pushes the tool back and forth. When you turn the screw, it moves the tool exactly where you want it. This makes the cuts sharp and neat. With the lead screw, your work is more accurate and precise.”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Commonly Used For Manufacturing Collets, And How Do They Impact The Performance Of The Collet System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Collets are often made from metal like steel or aluminum. Steel is strong and lasts a long time. Aluminum is lighter, making it easier to handle. The material affects how tightly the collet holds tools, which helps keep things safe while working. Better materials mean better performance!”}},{“@type”: “Question”,”name”: “Can A Lead Screw Be Upgraded Or Replaced In An Existing Metal Lathe To Improve Its Functionality, And If So, What Considerations Should Be Taken Into Account?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can upgrade or replace a lead screw in a metal lathe. This can help it work better and more smoothly. First, you need to check the size and type of the new lead screw. You should also ensure it fits well with the machine. Finally, consider how much money and time you can spend on this upgrade.”}},{“@type”: “Question”,”name”: “How Do Collet Sizes And Types Affect The Versatility And Usability Of A Metal Lathe For Various Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Collet sizes and types help hold different tools or materials tightly on a metal lathe. When you change collets, you can work with larger or smaller pieces. This makes your lathe more flexible for various jobs. Using the right collet lets you do more types of work easily and accurately. So, having different collets means you can be more creative in what you make!”}}]}