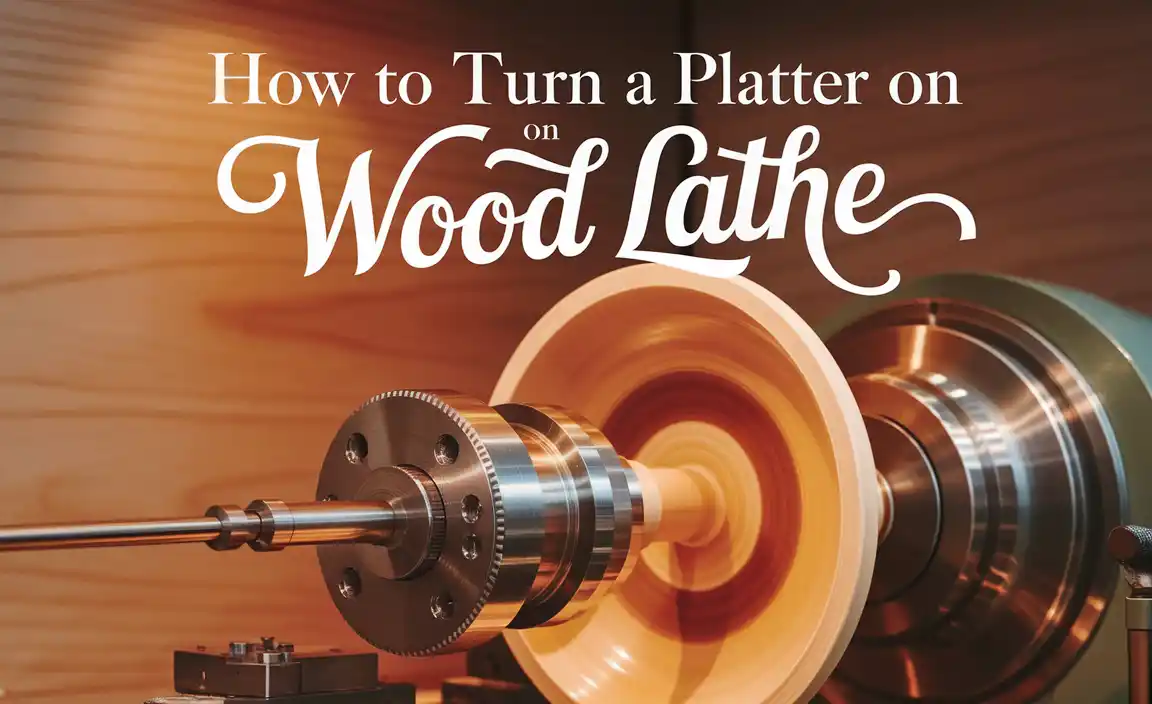

Have you ever wondered how a metal lathe helps create such precise parts? The secret often lies in the lathe collet system. This clever tool makes it easier to hold and secure materials. When you know how to care for it, your lathe will work better and last longer.

Imagine starting a project only to find your equipment isn’t working right. Frustrating, isn’t it? Regular maintenance can help avoid that. A well-kept lathe collet system makes a big difference in your work. It can lead to smoother cuts and better results overall.

Did you know that a small part of your lathe could save you time and money? By giving your lathe collet system the attention it deserves, you can keep it in top shape. Let’s dive into some easy tips for metal lathe maintenance and discover how to get the most out of your machine!

Lathe Collet System: Essential Metal Lathe Maintenance Tips

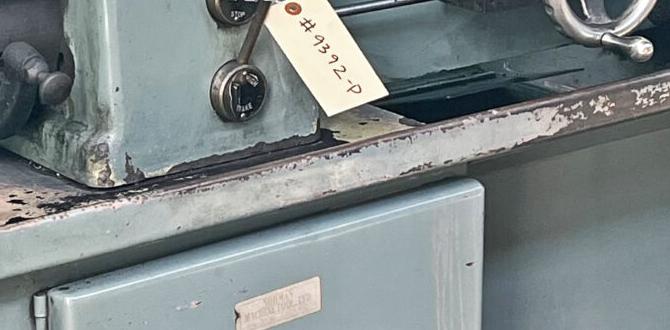

Lathe Collet System Metal Lathe Maintenance

Maintaining a lathe collet system is key for smooth, precise machining. Regular cleaning helps remove dust and chips that can cause issues. Did you know that a well-maintained collet can extend tool life? Also, checking for wear is vital. You wouldn’t want a worn collet ruining your work. Make sure to keep the collet surfaces smooth and lubricated. With proper care, your lathe can perform like new for years. Ready to keep your equipment in top shape?Understanding Lathe Collet Systems

Definition and purpose of collet systems in metal lathes. Different types of collet systems available.A collet system is like a tight hug for tools on a metal lathe. It grips the workpiece securely, allowing for precise cuts without any wiggling. Different types of collet systems are available, each offering unique features. For example, there are band collets, expandable collets, and step collets. Each type has a specific purpose, like a superhero in a team. Below is a quick look at these types:

| Type | Purpose |

|---|---|

| Band Collets | Great for larger items, like that oversized sandwich you thought you could eat! |

| Expandable Collets | Perfect for holding a variety of shapes – they’re the shape-shifters of the collet world. |

| Step Collets | Great for different sizes, like your collection of mismatched socks. |

Understanding these systems can make your lathe work smoother—like butter on a hot pancake!

Benefits of Using Collet Systems in Metal Lathes

Improved precision and accuracy in machining. Enhanced workpiece holding and stability during operations.Using collet systems in metal lathes has some fantastic perks! First, it boosts precision and accuracy in machining. Your parts will come out looking sharp, not like a toddler’s drawing! Second, these collets improve how your workpieces are held, enhancing stability during operations. No more pesky wobbles that turn your masterpiece into a scribble. With collets, you’re set for a smoother operation every time!

| Benefits | Description |

|---|---|

| Improved Precision | Collet systems help cut errors, making each piece exact. |

| Enhanced Stability | Workpieces stay put, preventing slips and slides. |

Choosing the Right Collet for Your Metal Lathe

Factors to consider when selecting a collet. Compatibility with different lathe models and applications.Picking the right collet for your metal lathe is key. First, think about the size of your lathe and what you will make. Not all collets fit every lathe, so double-check compatibility. Consider the material you are working with, too. Some collets excel with certain metals. And let’s be honest—nobody wants a collet that’s as stubborn as a mule! Keep your eyes on the prize: a well-chosen collet can make your work smoother and more precise.

| Factor | Consideration |

|---|---|

| Size | Matches the lathe |

| Material | Tough for tough jobs |

| Compatibility | Works with your model |

Step-by-Step Guide to Installing a Collet System

Preparing the lathe for collet system installation. Detailed installation steps.Before you start the installation, look after your lathe. Clean it well to remove any dust or oil. Check all parts for wear and damage. It’s important to work on a flat surface for safety. Here are the steps:

- Gather all tools needed for the collet system.

- Remove the chuck from the lathe spindle.

- Carefully attach the collet system onto the spindle.

- Tighten the system using the appropriate tools.

- Test the setup to ensure it works properly.

Following these steps will help your lathe work efficiently.

What maintenance does a collet system require?

To keep the collet system in good shape, clean it regularly, check for tightness, and replace worn parts as needed. Regular care extends the life of your equipment.

Lathe Maintenance Essentials

Routine maintenance practices for metal lathes. Importance of lubrication and cleaning.Keeping your metal lathe happy is key for smooth operations! Regular maintenance helps avoid bad surprises. Lubricating the moving parts makes them feel like they’re on a gentle vacation, while cleaning keeps dirt away. Think of it like brushing your teeth—no one wants a cavity, right? A quick wipe can go a long way! Remember, a little grease here and there can save you from a meltdown later on.

| Maintenance Task | Frequency |

|---|---|

| Check Lubrication | Daily |

| Clean Surfaces | Weekly |

| Inspect Belts | Monthly |

| Replace Worn Parts | As Needed |

By following these simple steps, your lathe will be smoother than butter! Remember, upkeep is the secret ingredient for success. So let’s keep those machines purring.

Troubleshooting Common Issues with Collet Systems

Identifying and resolving holding issues. Dealing with wear and tear on collets.Collet systems can sometimes have issues. First, check for holding problems. If your workpiece slips, ensure the collet is tightened properly. A worn collet can also cause this. Regular wear and tear happens over time. Inspect collets for cracks or deformities. Replace them if they look damaged. Here’s a quick checklist:

- Look for loose fittings.

- Check for cracks or chips.

- Ensure proper size for the workpiece.

- Inspect for dirt and debris.

What should I do if my collet is worn out?

If your collet wears out, you should replace it. A worn collet can impact machine accuracy. It’s essential for safe and effective work. Regular checks can help avoid problems.

Tips for Maximizing Longevity of Your Lathe Collet System

Best practices for usage and storage of collets. Routine checks and replacements to extend lifespan.Keep your lathe collet system in top shape with some smart practices! First, always store your collets in a dry place. Moisture is their nemesis, kind of like how broccoli hates being near chocolate. Regularly check for wear and tear. If your collets start looking like worn-out shoes, it’s time for replacements! A quick inspection every few months can save you a lot of trouble later.

| Best Practices | Frequency |

|---|---|

| Inspect for damage | Every 3 months |

| Clean after use | Always! |

| Replace worn collets | As needed |

Following these tips will surely boost the longevity of your lathe collet system. Think of it like giving your tools a spa day—every bit helps them feel fresh and ready for action!

Conclusion

In summary, a lathe collet system helps hold workpieces securely. Regular metal lathe maintenance keeps your machine running smoothly. Check the collet for wear and clean it often. By taking these steps, you improve accuracy and extend the lathe’s life. We encourage you to explore more articles on lathe care to boost your skills and knowledge!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Metal Lathe Maintenance:Sure! Here are some answers about lathe collet systems and taking care of metal lathes: 1. A lathe collet is a special tool that holds a piece of metal tight while you work on it. 2. To keep your lathe working well, always clean it after using it. 3. Check the oil in your lathe regularly to make sure it’s running smoothly. 4. Make sure to tighten the collet properly before you start, so the metal doesn’t slip. 5. If you notice any weird noises, stop and check your lathe right away to avoid problems.

Sure! I can help you with that. Please ask your question, and I’ll answer it clearly and simply.

What Is The Purpose Of A Collet System In A Metal Lathe, And How Does It Differ From Traditional Chucks?A collet system holds metal pieces very tightly when you work on them with a metal lathe. It grips the piece in a round shape, which helps keep everything balanced. This is different from traditional chucks, which grab from the outside. Collets can hold smaller pieces better and let you change them quickly. Overall, they help us make more precise and neat work!

How Can You Properly Maintain And Clean A Lathe Collet To Ensure Optimal Performance And Accuracy?To keep a lathe collet working well, start by removing it from the lathe carefully. Use a soft cloth and some mild cleaner to wipe it down. Check for dirt and small pieces that might get stuck, and clean those out. Make sure it’s dry before putting it back. Regular cleaning helps your machine work better and makes your projects turn out great!

What Are The Signs Of Wear Or Damage In Collets, And When Should They Be Replaced?You can spot wear or damage in collets by looking for cracks, chips, or bends. If the collet doesn’t hold the tool tightly, it’s also a sign it needs replacing. We should change collets if they look damaged or if they don’t work properly during use. Keeping them in good shape helps us work safely and effectively.

How Do You Correctly Set Up And Align A Collet In A Metal Lathe To Avoid Workpiece Vibration And Ensure Precision?To set up a collet in a metal lathe, first, clean both the collet and the workpiece. Next, place the workpiece into the collet and tighten it gently. Make sure the collet is straight and centered in the lathe. After that, check for any wobble by turning it slowly. If it wobbles, adjust it until it spins smoothly. This helps you make precise cuts without vibrations.

What Are The Best Practices For Storing Collets And Other Lathe Accessories To Prevent Corrosion And Damage?To keep your collets and lathe accessories safe, store them in a dry place. Use a toolbox or a drawer with a lid. You can also use a cloth to wipe them clean. Avoid leaving them in damp areas, as moisture can cause rust. Lastly, check them often to make sure they stay in good shape.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Metal Lathe Maintenance:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers about lathe collet systems and taking care of metal lathes: 1. A lathe collet is a special tool that holds a piece of metal tight while you work on it. 2. To keep your lathe working well, always clean it after using it. 3. Check the oil in your lathe regularly to make sure it’s running smoothly. 4. Make sure to tighten the collet properly before you start, so the metal doesn’t slip. 5. If you notice any weird noises, stop and check your lathe right away to avoid problems.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help you with that. Please ask your question, and I’ll answer it clearly and simply.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Collet System In A Metal Lathe, And How Does It Differ From Traditional Chucks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet system holds metal pieces very tightly when you work on them with a metal lathe. It grips the piece in a round shape, which helps keep everything balanced. This is different from traditional chucks, which grab from the outside. Collets can hold smaller pieces better and let you change them quickly. Overall, they help us make more precise and neat work!”}},{“@type”: “Question”,”name”: “How Can You Properly Maintain And Clean A Lathe Collet To Ensure Optimal Performance And Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a lathe collet working well, start by removing it from the lathe carefully. Use a soft cloth and some mild cleaner to wipe it down. Check for dirt and small pieces that might get stuck, and clean those out. Make sure it’s dry before putting it back. Regular cleaning helps your machine work better and makes your projects turn out great!”}},{“@type”: “Question”,”name”: “What Are The Signs Of Wear Or Damage In Collets, And When Should They Be Replaced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot wear or damage in collets by looking for cracks, chips, or bends. If the collet doesn’t hold the tool tightly, it’s also a sign it needs replacing. We should change collets if they look damaged or if they don’t work properly during use. Keeping them in good shape helps us work safely and effectively.”}},{“@type”: “Question”,”name”: “How Do You Correctly Set Up And Align A Collet In A Metal Lathe To Avoid Workpiece Vibration And Ensure Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a collet in a metal lathe, first, clean both the collet and the workpiece. Next, place the workpiece into the collet and tighten it gently. Make sure the collet is straight and centered in the lathe. After that, check for any wobble by turning it slowly. If it wobbles, adjust it until it spins smoothly. This helps you make precise cuts without vibrations.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Storing Collets And Other Lathe Accessories To Prevent Corrosion And Damage?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your collets and lathe accessories safe, store them in a dry place. Use a toolbox or a drawer with a lid. You can also use a cloth to wipe them clean. Avoid leaving them in damp areas, as moisture can cause rust. Lastly, check them often to make sure they stay in good shape.”}}]}