Have you ever wondered how to achieve perfect cuts on a metal lathe? One important part of that process is the lathe collet system. This special system holds the tools tightly in place. It sounds simple, but proper alignment can make a big difference.

Imagine trying to draw a straight line but your pencil keeps wobbling. Frustrating, right? The same thing happens when the tailstock isn’t aligned correctly. If the tailstock is off, your workpiece could end up crooked.

Many people don’t realize that small adjustments in the collet system can lead to huge improvements. Did you know that just a tiny misalignment can ruin a project? That’s why understanding how to align your metal lathe tailstock is crucial.

In this article, we will explore the steps you need to take. You’ll learn how to set up your lathe collet system for the best results. Get ready to bring your metalworking skills to the next level!

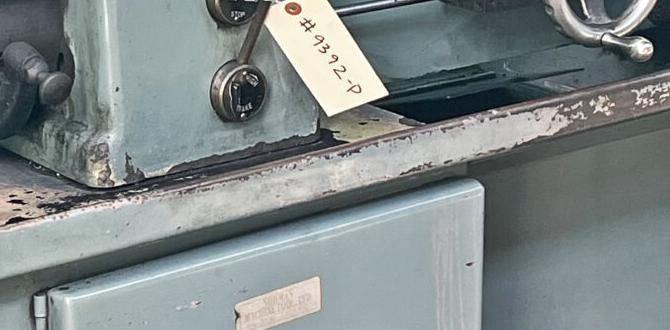

Lathe Collet System: Metal Lathe Tailstock Alignment Guide

Lathe Collet System and Tailstock Alignment

Proper lathe collet system use is key for precise work. Did you know that misalignment of the tailstock can cause serious mistakes? Accurate tailstock alignment ensures that workpieces are centered. This alignment prevents wobbly cuts and improves overall quality. A well-aligned lathe will save you time and frustration. Check your equipment often to maintain precision. Remember, small adjustments can make a big difference in your projects! Investing time in alignment will elevate your metalworking skills.Understanding Lathe Collet Systems

Definition and functionality of lathe collet systems. Advantages of using collets over traditional chucks.Imagine a metal lathe that holds your workpiece tight, like a big bear hug! That’s what lathe collet systems do. They grip items with precision. Unlike traditional chucks, collets are more reliable and provide less wobble. This means your work is smoother, just like butter on toast!

Using collets is like choosing a superhero over a sidekick: they save time and improve accuracy. They also allow quicker tool changes, making work feel like a breeze instead of a puzzle. So, why not give your projects the trusty grip they deserve?

| Feature | Collets | Traditional Chucks |

|---|---|---|

| Grip Accuracy | High | Moderate |

| Change Speed | Fast | Slower |

| Wobble | Minimal | More |

The Importance of Tailstock Alignment

Explanation of tailstock alignment and its significance in machining. Common issues arising from misalignment and their effects on precision.Tailstock alignment is key to smooth machining. It helps keep the tailstock and the spindle in line. Proper alignment ensures that the tool cuts evenly and accurately. If the tailstock is misaligned, it can cause:

- Poor surface finish

- Increased wear on tools

- Loss of precision in workpieces

Misalignment leads to problems that can be frustrating and time-consuming. Regular checks can help prevent these issues. Always aim for perfect alignment for the best results!

What happens if the tailstock is misaligned?

Misalignment leads to poor cuts, bad surface finishes, and extra wear on tools. Regular checks will help you keep everything running smoothly.

Step-by-Step Guide to Aligning the Tailstock

Tools required for tailstock alignment. Detailed procedure for proper tailstock alignment.To align the tailstock correctly, you’ll need a few tools. Gather these items:

- Calipers or a ruler

- Tapered alignment bar

- Wrenches

- Hex keys

- Leveling tools

Start by checking if your lathe is level. Use a ruler to measure the tailstock’s position. Adjust it so it matches the spindle. Tighten the screws firmly. Double-check your work for accuracy. This helps ensure smooth cuts and better results!

What is the purpose of tailstock alignment?

Tailstock alignment ensures that your workpiece centers properly. A well-aligned tailstock helps produce accurate and finished projects without errors.

Troubleshooting Common Tailstock Alignment Problems

Identifying symptoms of a misaligned tailstock. Solutions and adjustments to correct alignment issues.Is your tailstock acting like a stubborn mule, refusing to align? Let’s spot the signs of misalignment. Common symptoms include uneven cuts and weird noises. If your workpiece looks like a banana instead of a straight stick, your tailstock might need a little TLC.

To fix it, don’t panic! Start with a simple adjustment. Loosen the tailstock lock screws, then align it with the spindle. Tighten those screws once it’s straight. For tricky cases, check horizontal and vertical positioning using a level.

| Symptom | Possible Cause | Fix |

|---|---|---|

| Uneven cuts | Misaligned tailstock | Adjust and tighten |

| Weird noises | Loose components | Check fasteners |

With these tips, your tailstock will be back on track and ready to rock! Remember, a happy tailstock means smoother projects and fewer headaches.

Maintaining the Lathe Collet System for Optimal Performance

Regular maintenance tips for collets and tailstocks. Best practices for cleaning and storing collets.Keeping your lathe collet system in top shape is important. Regular maintenance makes sure everything works well. Here are some tips:

- Check and clean collets often. Wipe off dirt and oil.

- Inspect the tailstock. Ensure it lines up perfectly with the lathe.

- Store collets in a dry, clean space. Use a box or container to keep them safe.

These simple steps help your lathe work better and last longer.

How to clean collets properly?

To clean collets, use a soft cloth with mild soap. Avoid harsh chemicals. Rinse and dry thoroughly. This keeps them rust-free and functional.

Enhancing Machining Accuracy with Advanced Techniques

Techniques to improve the overall accuracy of your metal lathe. Utilizing digital tools for precise tailstock alignment.For better machining accuracy, consider using digital tools. Advanced laser aligners can help you set your tailstock perfectly. This means fewer wobbles and a smoother cut. If you’ve ever tried to cut a straight line with a crooked pencil, you know how important alignment is! A simple adjustment can lead to amazing improvements in your work.

| Technique | Description |

|---|---|

| Digital Alignment Tools | Use laser or digital calipers to measure precisely. |

| Regular Calibration | Check tools often to keep them accurate. |

Small steps like these turn frustrating projects into successful creations. Remember, a perfectly aligned tailstock is your best friend in maintaining lathe collet system accuracy!

Case Studies: Successful Tailstock Alignment in Industry

Realworld examples of tailstock alignment solutions. Impact of proper alignment on quality and production efficiency.Many companies have seen great results with proper tailstock alignment. Here are some real-world examples:

- A tool shop improved their part accuracy by 25%. This led to fewer mistakes and less wasted material.

- A manufacturer increased their production speed by 30% after aligning their tailstock. This made their machines run smoother.

- A factory cut down machine downtime by 40% with correct alignment. This kept their workers busy and happy.

Each case shows how important tailstock alignment is. Companies that focus on this see better quality and quicker production. Proper alignment is more than just a task; it’s a key to success.

Why is tailstock alignment important?

Tailstock alignment helps keep the workpiece steady. A well-aligned lathe makes everything work right, leading to better results.

Benefits of Proper Tailstock Alignment:

- Improved part quality

- Lower waste of materials

- Faster production rates

- Less machine maintenance

Resources for Further Learning

Books, tutorials, and online courses on lathe operation and maintenance. Recommended communities and forums for metalworking enthusiasts.Learning about metal lathes can be fun and rewarding! Several books and tutorials are available to help you understand lathe operation and maintenance. Online courses can take your skills to the next level. Don’t forget to join communities and forums; they are fantastic for connecting with other metalworking enthusiasts. Remember, even experts love to share their tips and funny mishaps!

| Resource Type | Recommended Resources |

|---|---|

| Books | “The Lathe Book” by Ernie Conover |

| Tutorials | YouTube channels like “This Old Tony” |

| Online Courses | Udemy offers a great lathe operation course! |

| Forums | Check out “Practical Machinist” for community advice. |

With these resources, you’ll be on your way to becoming a metal lathe master in no time! Who knew making chips could be so much fun?

Conclusion

In conclusion, aligning the tailstock on your metal lathe using a collet system is essential for precision. Proper alignment helps improve accuracy and reduces errors in your projects. Remember, you can check alignment with simple tools like a dial indicator. Try aligning your tailstock today to enhance your skills. For more tips, keep reading or watch tutorial videos!FAQs

What Are The Steps For Aligning A Lathe Tailstock With The Spindle To Ensure Proper Collet Engagement?To align the lathe tailstock with the spindle, first, check if the lathe is turned off. Use a ruler or a special tool to measure the distance from the spindle to the tailstock. If they don’t match, you need to adjust the tailstock by moving it to the right spot. Tighten it once it’s aligned. Finally, test it to make sure everything is working well together.

How Can Improper Tailstock Alignment Affect The Precision Of Workpieces When Using A Collet System On A Metal Lathe?If the tailstock is not aligned correctly, it can cause problems when you use a collet system on a metal lathe. This means the workpiece may not fit tightly and can move around while you’re working. When the piece moves, it can create shapes that aren’t right or make cuts that are uneven. This can lead to mistakes in the final product, making it less precise and more difficult to use. So, it’s really important to align the tailstock properly!

What Tools Are Commonly Used To Check And Adjust The Alignment Of The Tailstock In Relation To The Lathe’S Spindle?To check the alignment of the tailstock, you can use a few simple tools. A dial indicator is helpful because it shows how closely things line up. A machinist’s square can also help you see if everything is straight. Lastly, a straightedge is handy for checking if surfaces are even. These tools help make sure the tailstock and spindle work well together.

How Does The Type Of Collet System Used Influence The Alignment Process For The Tailstock On A Metal Lathe?The collet system helps hold the metal piece tightly. If the collet is not aligned well, it can make the tailstock off-center. This means the tailstock won’t help the metal piece spin correctly. When you use a better collet, it keeps everything straight. This makes your work easier and more exact.

What Are The Signs That Indicate A Tailstock Misalignment, And How Can These Issues Impact Collet Performance?You can tell if a tailstock is misaligned by looking for uneven cuts or vibrations when using it. If the tailstock isn’t straight, it can make collets—small tools that hold things—work poorly. This means your workpieces might not fit well or might wobble. Always make sure everything is lined up to get the best results!