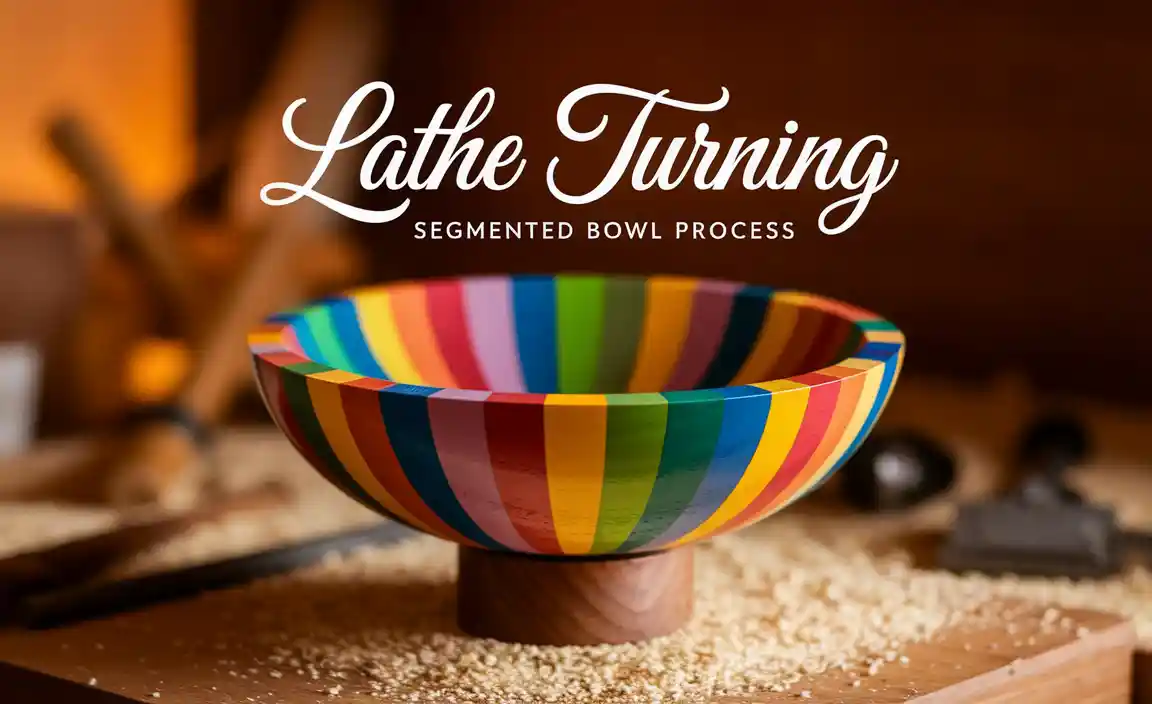

Have you ever wondered how metal parts are shaped with such precision? The magic often happens on a metal lathe. One key to this magic is the lathe collet system. This system holds the workpiece tightly and securely, allowing for detailed turning. But what exactly is taper turning, and why is it important?

Imagine you’re trying to make a perfect cone. You want it to be smooth and exactly the right size. That’s where taper turning comes in. It lets you shape objects in a way that would be hard to do by hand. Did you know that even small mistakes in taper turning can lead to big problems later on? This is all about accuracy and control.

In this article, we’ll explore how the lathe collet system works with taper turning. We’ll look at its benefits, tips for using it, and why it’s a favorite among metalworkers. Are you ready to dive into the world of metal lathes? Let’s get started!

Lathe Collet System For Metal Lathe Taper Turning Techniques

Understanding Lathe Collet Systems in Metal Lathe Taper Turning

Lathe collet systems are essential tools for metalworking. They securely hold workpieces while using a lathe. Taper turning, a common task, helps create angled surfaces. Did you know that a simple change in angle can enhance a part’s function? Collets provide better precision than other tools, making them popular among craftsmen. Understanding how to use a lathe collet system can lead to more accurate projects and smoother operations. Ready to improve your metalworking skills?What is a Lathe Collet System?

Definition and purpose of lathe collet systems. Types of collet systems and their applications.A lathe collet system holds workpieces firmly during machining. It is essential for precise shaping and cutting. Collets work by gripping the item tightly. This helps in taper turning operations. There are different types of collet systems:

- Types: Standard collets, ER collets, and Special collets.

- Applications: Used in woodturning, metalworking, and CNC machining.

Each type has its own purpose and benefits. The right collet improves accuracy and efficiency in lathe operations.

What are the benefits of a lathe collet system?

Collet systems offer better grip and higher accuracy. They allow easy switching between tools. This saves time and effort during machining tasks.

Types of Collets Suitable for Taper Turning

Description of common collet types (e.g., ER, TG, etc.). Advantages and disadvantages of each collet type for taper turning.Collets come in various shapes and sizes, each with its own quirks! The ER collet is a popular choice because it holds tools snugly and fits many sizes. However, it might not be the best friend for quick changes. TG collets are great for heavy-duty work, but they can be a bit more challenging to use.

| Collet Type | Advantages | Disadvantages |

|---|---|---|

| ER | Fits many tools; easy to find | Slower tool changes |

| TG | Strong grip for heavy cutting | Difficult for new users |

So, choose wisely! Each collet has its perks and quirks like your favorite socks. Happy taper turning!

Setting Up a Lathe Collet System for Taper Turning

Stepbystep guide to installing a collet system. Tips for ensuring accuracy and precision.Setting up a lathe collet system for taper turning is easy if you follow clear steps. Begin by cleaning the lathe and checking for any damage. Next, install the collet holder in the spindle. Make sure it is well tightened. Insert the collet and secure it tightly. This will help keep things in place. Finally, adjust the tailstock for the correct angle.

Here are some tips for accuracy:

- Use a dial indicator to check alignment.

- Take test cuts to verify settings.

- Measure often for best results.

- Keep tools sharp for clean cuts.

A precise setup leads to better taper turning. Remember, every little detail counts!

What is the purpose of a lathe collet system?

A lathe collet system holds the workpiece firmly in place while performing tasks such as taper turning.

Best Practices for Taper Turning Using Collet Systems

Techniques for achieving optimal results. Common mistakes to avoid during taper turning.Taper turning with collet systems can yield great results when done right. To achieve the best outcome, focus on these techniques:

- Use the correct speed for your lathe.

- Make sure the workpiece is secure in the collet.

- Utilize sharp cutting tools for clean cuts.

Avoid these common mistakes:

- Don’t rush the process; take your time.

- Check the setup often to avoid errors.

- Don’t forget to lubricate your tools.

Following these tips will help you achieve optimal results.

What should I remember while taper turning?

Pay attention to your settings, tool sharpness, and take breaks to check your work regularly.

Maintenance and Care for Lathe Collet Systems

Routine maintenance procedures. Troubleshooting common issues.To keep your lathe collet system in top shape, regular maintenance is key. Making a clean work area avoids dirt buildup. Check the system for signs of wear. If you notice strange noises, it might be time for an inspection. Here are some quick tips:

- Clean collets after each use.

- Inspect for cracks or chips.

- Lubricate moving parts regularly.

- Store tools properly to avoid damage.

Common issues include the collet not tightening properly or excessive vibration. If you face these problems, check for dirt in the threads or a loose fit.

How do I clean a lathe collet system?

Use a soft brush and a cloth. Wipe off all dirt and chips to prevent issues. Regular cleaning helps your tools work better.

Comparing Collet Systems to Other Workholding Methods

Pros and cons of collet systems versus chucks and fixtures. Scenarios where collet systems are more beneficial.Collet systems offer a fast and precise way to hold workpieces, unlike chucks and fixtures, which can be clunky. They work like a cozy hug for your metal, grabbing it tightly to reduce vibrations. However, they can be a bit pricey. Chucks are cheaper and easier to find, but they may jiggle your piece like a bad dance move. For small projects or precision work, collets shine like a star on stage. Below is a handy table to summarize these differences:

| Method | Pros | Cons |

|---|---|---|

| Collet Systems | High accuracy, quick setup | More expensive |

| Chucks | Cheaper, widely available | Less precise |

| Fixtures | Stable for big jobs | Can be bulky |

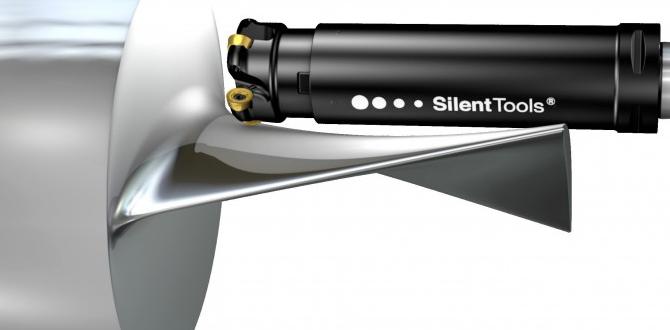

Innovations and Trends in Lathe Collet Systems

Recent advancements in collet technology. Future trends in taper turning and collet systems.Recent advancements in collet technology are exciting. New materials make collets stronger and lighter. These developments improve performance during taper turning. Future trends show a push towards automation and smart technology. Machines can do more precise tasks with less effort. Here are some key points to note:

- Use of advanced materials

- Automation in collet systems

- Improved accuracy in taper turning

As technology grows, we can expect even better tools. They will make metalworking faster and easier.

What are the benefits of modern collet systems?

Modern collet systems increase efficiency and reduce errors in metal turning. They help create smoother and cleaner finishes on workpieces.

Conclusion

In summary, a lathe collet system helps secure materials for taper turning with ease. It provides better precision and stability than other methods. Understanding this system means better quality work for you. Explore different collets and practice using them on your metal lathe. Keep learning, and you’ll become more skilled at crafting amazing projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Taper Turning On Metal Lathes:Sure! Here’s a short answer for you. A lathe is a machine that helps shape metal. Collet systems hold the metal tightly so it doesn’t move. Taper turning means making one end of the metal smaller or pointy. This way, we can create different shapes for tools or pieces we need.

Sure! Please provide the question you would like me to answer.

What Are The Advantages Of Using A Collet System Over A Standard Chuck For Taper Turning On A Metal Lathe?Using a collet system is better than a standard chuck for taper turning on a metal lathe. Collets hold the workpiece tighter, so it won’t move around. This gives you more accuracy while working. They are also easier to change quickly, saving you time. Overall, collets help you make better-looking projects!

How Do You Determine The Appropriate Collet Size And Type For A Specific Workpiece When Turning A Taper?To choose the right collet size, first measure your workpiece. You can use a ruler to find its diameter. Next, pick a collet that matches that size. The type of collet depends on your machine and the shape of your workpiece. If you’re turning a taper, a collet that holds the workpiece firmly is best.

What Are The Essential Steps To Set Up A Lathe Collet System For Accurately Taper Turning A Metal Shaft?To set up a lathe collet system, first, choose the right collet size for your metal shaft. Next, you need to securely attach the collet to the lathe. Then, place the metal shaft inside the collet and tighten it firmly. After that, adjust the lathe’s cutting tool to the correct angle for taper turning. Finally, start the lathe and carefully turn the metal to create the taper shape you want.

How Do You Calculate The Taper Angle And Dimensions Required For A Specific Application When Using A Metal Lathe?To calculate the taper angle, you first decide how wide you want the part to be at each end. Then, find out how long the part is. You can use a simple formula: tangent of the angle equals the difference in width divided by the length. After that, you can measure and mark the metal piece on the lathe. Finally, you carefully cut the metal to shape it into a taper, following your marks.

What Troubleshooting Techniques Can Be Employed If The Taper Turned On A Metal Lathe Is Not Meeting The Desired Specifications?If the taper isn’t right on the metal lathe, you can check a few things. First, make sure the tool is sharp and clean. Then, check if the lathe is set up correctly. You should also look at the speed and feed rate to see if they match the job. Finally, try measuring your work again to find out where it’s off.