Have you ever wondered how metalworkers achieve precision in their projects? One key to their success lies in the lathe collet system. This upgrade can transform a regular metal lathe into a powerful tool. Imagine being able to hold workpieces more securely. Wouldn’t that make your projects easier and more accurate?

Many hobbyists and professionals alike find that switching to a collet system offers benefits they never expected. Did you know a collet can grip objects more evenly than a standard chuck? This means less vibration and better results. It’s like having a special grip that helps you do your best work every time.

In this article, we will explore why upgrading your metal lathe with a collet system is a smart choice. We’ll share tips on how to make this change and why it can boost your skills. Are you ready to take your metalworking to the next level?

Lathe Collet System: Enhance Your Metal Lathe Upgrade

Lathe Collet System Metal Lathe Upgrade

Upgrading to a lathe collet system can change your metalworking experience. This upgrade improves accuracy and reduces workpiece distortion. Collets grip the tools more tightly, preventing slippage. Have you ever struggled to keep your materials stable? With this system, that frustration fades away. Plus, collets come in different sizes, allowing flexibility for various projects. Imagine completing tasks faster while achieving better results. It’s a simple upgrade with big benefits!What is a Lathe Collet System?

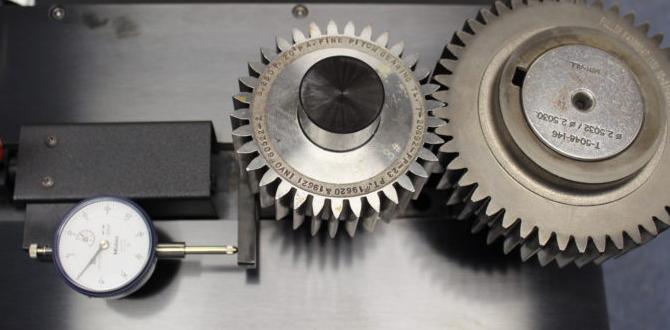

Definition and components of a lathe collet system.. Advantages over traditional chucks for metal lathe applications..A lathe collet system holds workpieces tightly and accurately. It consists of a collet, a sleeve, and a spindle. The collet grips the material, making it easy to work with. This system is better than traditional chucks because it offers:

- Improved accuracy

- Faster setup times

- Less vibration

- Versatile gripping options

These advantages make the lathe collet system a smart choice for metal lathe upgrade.

What are the benefits of using a lathe collet system?

Using a lathe collet system improves grip and precision, leading to better results in metalworking.

Benefits of Upgrading to a Collet System

Improved accuracy and precision in machining.. Enhanced grip and reduced workpiece slippage during operations..Upgrading to a collet system in your lathe brings many perks. First, it boosts accuracy and precision in machining. This means your pieces fit together like a perfect puzzle! Second, it offers a stronger grip, reducing pesky workpiece slippage during operations. Imagine trying to hold a slippery fish; it’s much easier with a firm grip! Here’s a quick look at the benefits:

| Benefit | Description |

|---|---|

| Improved Accuracy | Enhanced precision in machining tasks. |

| Stronger Grip | Less chance of workpieces slipping during operation. |

So, say goodbye to wobbly pieces and hello to smooth sailing in your projects!

Installation Process for Lathe Collet Systems

Stepbystep guide to installing a collet system on a metal lathe.. Tools and materials needed for installation..Installing a collet system on your metal lathe can be easy and fun! Start by gathering some tools. You will need a wrench, a screwdriver, and maybe even a snack (because why not?). First, remove the old chuck—don’t lose those screws! Next, fit the new collet system onto the spindle. Tighten everything well but not too tight, or you’ll be asking your metal lathe to do a yoga pose! Finally, test it out and be amazed by your upgraded tool.

| Tools Needed | Why You Need Them |

|---|---|

| Wrench | To tighten things up! |

| Screwdriver | For those pesky screws! |

| Snack | Keep your energy up! |

Always remember, a calm and fed brain works best in the shop!

Key Considerations Before Upgrading

Evaluating your lathe’s compatibility with a collet system.. Factors influencing collet size and type selection..Before jumping into the exciting world of lathe collet systems, it’s smart to check if your lathe can handle it. Not all lathes are created equal. Finding the right match is crucial for a smooth upgrade.

Think about the size and type of collet you need. Different projects might require different sizes. Choosing the wrong one is like wearing shoes that are two sizes too big – you’ll trip a lot!

| Collet Type | Best For |

|---|---|

| ER collets | General purposes |

| DA collets | High precision work |

| 3-Jaw Chucks | Irregular shapes |

Make sure you pick the right collet for your lathe! After all, a good fit makes for a happier machine, and who doesn’t love a cheerful lathe?

Best Practices for Using a Lathe Collet System

Tips for loading and unloading workpieces safely and efficiently.. Maintenance tips to prolong the lifespan of collets..Using a lathe collet system can feel like magic, but it helps to follow some best practices to keep things running smoothly. First, always load and unload your workpieces with care. Treat them like eggs—nobody wants a yolk on the floor. Keep your workspace clean and organized, too. For maintenance, wipe your collets clean after each use. A little grease can go a long way; think of it as a spa day for your tools. This keeps them happy and working longer!

| Tips for Safe Handling | Maintenance Tips |

|---|---|

| 1. Handle workpieces gently. | 1. Clean collets after use. |

| 2. Use protective gear. | 2. Apply lubrication regularly. |

| 3. Keep hands clear during operation. | 3. Store collets in a dry place. |

Cost Comparison: Collet Systems vs. Traditional Chuck Systems

Breakdown of expenses involved in upgrading.. Longterm financial benefits of investing in a collet system..Upgrading to a collet system has some costs, but it can save you money in the long run. First, let’s check out some numbers:

| System Type | Initial Cost | Maintenance Cost |

|---|---|---|

| Collet System | $300 | $20/year |

| Traditional Chuck | $200 | $50/year |

At first glance, the collet system seems pricey. But wait! With low maintenance costs and better precision, it pays off. You’ll spend less on repairs and materials. Plus, collets grip better, making flukes less likely. It’s like choosing a salad over fries—better for your wallet and waistline! So, investing in a collet system now can turn into savings and gains later.

Real User Experiences and Feedback

Testimonials from metal lathe users who upgraded to a collet system.. Case studies showcasing improved machining outcomes..Many metal lathe users who upgraded to a collet system couldn’t be happier. One user shared, “My workpiece wobbled less than a toddler on roller skates!” They noticed smoother cuts and less chatter, which means better quality pieces. Another case study revealed a 30% boost in production speed. Users were able to finish jobs faster, leaving more time for coffee breaks. Below is a glimpse of real user feedback:

| User | Feedback | Improvement |

|---|---|---|

| John D. | “No more wobbles!” | Smoother cuts |

| Sara T. | “Saved me time and materials!” | Less waste |

| Mike R. | “I can finish a project and still have lunch!” | Increased speed |

Where to Buy and What to Look for in a Collet System

Recommended suppliers and online resources for purchasing a collet system.. Key features to evaluate when selecting a collet system for your lathe..Looking for a collet system? You’re not alone! Many hobbyists and pros alike want to upgrade their metal lathes. You can find awesome supplies at trusted places like Amazon, MSC Industrial Supply, and local machine shops. Be sure to check features like size compatibility and material quality. Remember, a good collet means less wobble and more precision—plus, you won’t be chased by a runaway workpiece! Here’s a quick comparison:

| Supplier | Features | Price Range |

|---|---|---|

| Amazon | Wide selection | $20 – $200 |

| MSC Industrial | Quality brands | $30 – $250 |

| Local Machine Shops | Personalized advice | Varies |

In the quest for the perfect collet system, always remember to check reviews and ask fellow machinists. A little research goes a long way in avoiding buyer’s remorse!

Conclusion

In conclusion, upgrading to a lathe collet system can greatly improve your metal lathe’s performance. It provides better precision and faster tool changes. You’ll enjoy enhanced control while working on your projects. If you’re ready for this upgrade, consider researching different collet systems for your lathe. This can help you choose the best fit for your needs. Happy machining!FAQs

What Are The Advantages Of Using A Collet System Over A Traditional Chuck System On A Metal Lathe?Using a collet system is better for a few reasons. First, it holds the metal pieces more tightly, so they don’t move around while you work. Second, it grips different sizes better, which means you can switch pieces quickly. Lastly, it’s easier to change parts, saving you time. This helps you finish your work faster and more accurately!

How Do You Select The Appropriate Collet Size And Type For Specific Machining Tasks On A Lathe?To choose the right collet for your lathe, you first look at the size of your workpiece. You need a collet that matches how big the piece is. Next, think about the material you’re working with. Some collets hold better for certain materials. Finally, make sure the collet fits your lathe properly, so it works safely and well.

What Are The Key Specifications To Consider When Upgrading To A Collet System For Improved Precision And Efficiency?When upgrading to a collet system, you should think about a few important things. First, check the size of the collets so they fit your tools. Next, look for materials that are strong and durable. A good gripping force is important to hold your tools tightly. Finally, consider how easy it is to change the collets for quicker work.

How Can A Lathe Collet System Enhance Workpiece Gripping Compared To Other Clamping Methods?A lathe collet system grips workpieces better than other methods. It holds the piece tightly in one place. This keeps it stable, so it won’t move while you work. With a collet, you can quickly change pieces too. This makes your work faster and easier!

What Steps Are Involved In Installing And Calibrating A Collet System On An Existing Metal Lathe?To install a collet system on your metal lathe, follow these steps. First, turn off the machine and unplug it for safety. Next, remove the old chuck to make space for the collet system. Then, attach the collet holder tightly to the lathe. Finally, insert a collet and check if it’s secure before plugging in the machine again.