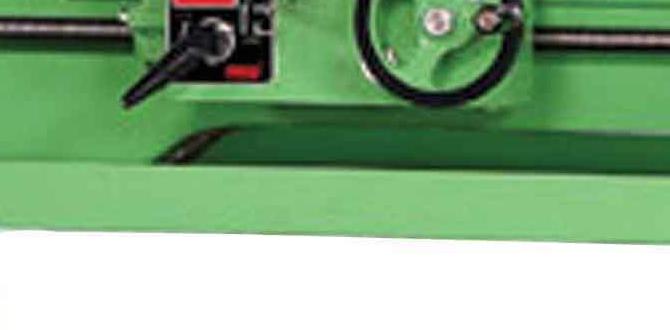

Have you ever wondered how a lathe works with perfect precision? The secret often lies in the lathe collet system. This handy tool helps hold your metal pieces tightly so you can shape them just right. But how does it all connect? That’s where a good wiring diagram comes in.

Picture this: You’re ready to start your metalworking project, but something feels off. You glance at the wiring and think, “What’s wrong here?” Understanding the metal lathe wiring diagram can save you time and trouble. It makes everything easier and safer!

In this article, we will explore the lathe collet system and how it relates to the wiring of a metal lathe. Let’s dive into this fascinating world and unlock the mysteries together!

Lathe Collet System: Metal Lathe Wiring Diagram Explained

Lathe Collet System Metal Lathe Wiring Diagram

A lathe collet system helps grip and hold materials securely. Understanding the wiring diagram for a metal lathe can be a little tricky. It shows how to connect different parts for smooth operation. Did you know that a good wiring setup can make a big difference in how well your lathe works? By learning the correct connections, you can ensure your machine runs efficiently and safely. It’s important for anyone working with lathes to grasp these concepts!What is a Lathe Collet System?

Definition and purpose of collet systems in metal lathes. Types of collets commonly used in machining.A lathe collet system holds pieces of metal securely in place while they spin. Think of it as a fancy clamp that gives your projects a tight hug! Collets come in different shapes and sizes, fitting various tools and materials. They get the job done without a fuss. Here’s a quick look at some common types:

| Type of Collet | Description |

|---|---|

| 5C Collet | Most widely used collet, perfect for holding cylindrical parts. |

| ER Collet | Great for versatility, used in milling and lathes. |

| TG Collet | Sturdy and reliable, perfect for high-speed operations. |

Collets are important because they keep things steady, making machining easier and more accurate. So, next time you see a lathe, remember the trusty collet that holds it all together—like a best friend, but with more metal!

Benefits of Using a Collet System on Metal Lathes

Enhanced precision and grip on workpieces. Comparison with traditional chuck systems.Using a collet system on metal lathes brings many perks. First, it offers better precision and holds workpieces tightly. This means your projects look sharper, not like they’ve been through a blender! What’s the difference with chuck systems, you ask? Chuck systems may let slip-ups happen, like a slippery banana peel. Meanwhile, collets grip every time. Here’s a simple comparison:

| Feature | Collet System | Chuck System |

|---|---|---|

| Precision | High | Moderate |

| Grip Strength | Strong | Less Strong |

| Setup Time | Quick | Longer |

In short, choosing a collet system is like picking a superhero for your metal lathe. More power and precision are always a win!

Essential Wiring Components for Metal Lathe Operation

Identification of necessary wiring components for a lathe collet system. Explanation of electrical connections and their importance in operation.Before you start making metal magic with your lathe, you need to understand the essential wiring components. These parts help keep things running smoothly. Key elements include the power supply, which gives energy, and the switches that control the machine. Next, we have connectors that join all the wires, ensuring everything works like a well-oiled machine—no squeaks or hiccups here! Below is a simple table showing these components:

| Component | Function |

|---|---|

| Power Supply | Provides energy to the lathe |

| Switches | Controls machine operation |

| Connectors | Links wires together |

Proper electrical connections are crucial. Without them, you might end up with a fancy paperweight, not a working lathe. So, be sure to check those wires—no one wants a shocking surprise!

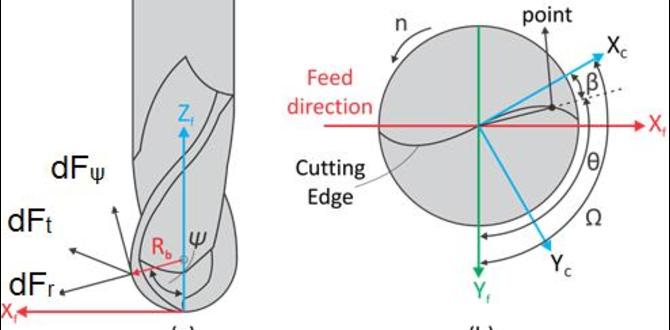

Step-by-Step Wiring Diagram for Metal Lathes

Visual representation of a wiring diagram for a lathe collet system. Detailed description of each wiring connection in the diagram.Wiring a metal lathe can seem tricky, but it’s a piece of cake with the right diagram! Let’s break it down step by step. Picture wires connecting various parts, just like a puzzle. Each wire has a specific job, ensuring the lathe runs smoothly. Here’s a quick look at those connections:

| Connection | Description |

|---|---|

| Power Supply | Feeds electricity to the entire system. |

| Motor Connections | Controls the speed and direction. Go fast or go home! |

| Collet System | Holds the material tightly for smooth cutting. |

Follow the diagram carefully, and you’ll have your lathe humming in no time! Remember, safety first—don’t wire it while wearing a clown suit! Your fingers will thank you later.

Safety Precautions When Wiring a Metal Lathe Collet System

List of essential safety measures during installation and operation. Common mistakes to avoid in wiring and setup processes.Working with metal lathes can be exciting, but safety is very important. Here are some key safety measures to follow:

- Always wear safety glasses to protect your eyes.

- Keep your workspace clean and organized.

- Disconnect power when making adjustments.

- Check all wires for damage before use.

Avoid these common mistakes:

- Never rush the wiring process.

- Don’t ignore the manual’s instructions.

- Don’t work alone if you’re unsure.

Being careful can help you stay safe while you enjoy your project!

What are common safety mistakes when setting up a lathe?

Many people forget to turn off the power while adjusting tools. Others skip checking cable conditions. This can lead to accidents. Always follow safety rules to keep yourself safe and your equipment running well.

Common Issues with Lathe Collet Systems and Troubleshooting

Identification of frequent problems encountered with collet systems. Troubleshooting tips to resolve common issues effectively.Collet systems can be tricky. Common problems include wrong sizing, poor gripping, and wear and tear. These issues can stop your lathe from working well. Here are some simple ways to troubleshoot:

- Check if the collet fits your workpiece.

- Clean the collet to ensure a tight grip.

- Inspect for damages like chips or cracks.

These tips can help you keep your lathe working smoothly and efficiently.

What are common lathe collet system problems?

Common issues include slippage, misalignment, and wear. Proper care and maintenance can prevent these problems.

Maintenance Tips for Longevity of Collet Systems

Best practices for maintaining a lathe collet system. Importance of regular checks and cleaning routines.Keeping your collet system in top shape helps it last longer. Regular checks and cleaning routines are key. Here are some best practices to follow:

- Inspect the collet for chips or dust after each use.

- Clean it with a soft brush to avoid damage.

- Lubricate moving parts to keep them working smoothly.

- Store the collet in a dry place to prevent rust.

These simple steps will help you get the best performance from your collet system.

Why is maintenance important for collet systems?

Maintaining collet systems ensures they work well and last longer. Regular care prevents problems and keeps everything running smoothly.

Comparative Analysis of Collet Systems vs. Other Workholding Methods

Pros and cons of collet systems in comparison to other workholding technologies. Situational examples that highlight advantages in specific machining scenarios.Let’s dive into the pros and cons of collet systems compared to other workholding methods. Collets are like snug pajamas for your tools—they keep things tight and secure. However, they sometimes can’t handle larger or heavier items, leaving us with a bit of a dilemma. In contrast, chucks can hold a variety of sizes but often need a bit more setup time. For example, in precision machining, collets shine. They grip small parts perfectly, making them ideal for detailed jobs. On the other hand, for larger parts, a chuck might make more sense.

| Workholding Method | Pros | Cons |

|---|---|---|

| Collet System | High precision, quick setup | Limited size range |

| Chucks | Versatile size handling | Longer setup time |

In machining, knowing which system to use can save time and energy. For small, intricate jobs, collets are the way to go. But when it comes to heftier projects, maybe let those chucks take the stage!

Conclusion

In summary, a lathe collet system helps you hold materials tightly while working. Understanding the metal lathe wiring diagram is essential for safe use. This knowledge ensures your projects go smoothly and efficiently. We encourage you to explore more about lathe systems and wiring. Practicing these concepts will make you a better machinist. Let’s keep learning together!FAQs

Sure! Here Are Five Questions Related To The Lathe Collet System And Wiring Diagrams For Metal Lathes:Sure! Here are five questions about lathe collet systems and wiring diagrams for metal lathes: 1. What is a lathe collet? A lathe collet holds a tool or part tightly while you work on it. 2. How do you switch tools in a lathe collet? You loosen the collet, change the tool, and then tighten it again. 3. Why is it important to use the right collet size? Using the right size keeps the tool secure and helps you work better. 4. What is a wiring diagram for a metal lathe? A wiring diagram shows how to connect the electrical parts of the lathe. 5. How can you find a good wiring diagram? You can check the user manual or look online for diagrams matching your lathe model.

Sure! Please share the question you want me to answer, and I’ll be happy to help.

What Are The Key Components Of A Lathe Collet System, And How Do They Work Together To Secure Workpieces?A lathe collet system has three main parts: the collet, the collet nut, and the spindle. The collet is a small sleeve that holds the workpiece tightly. You place the workpiece inside the collet, and then screw the collet nut onto it. This tightens everything, keeping the workpiece secure while the lathe spins it. Together, these parts make sure your material stays in place so you can shape or cut it safely.

How Do You Properly Wire The Electrical Components Of A Metal Lathe To Ensure Safe And Efficient Operation?To wire a metal lathe safely, first, turn off the power. Connect the wires to the motor, following the color codes. Then, plug the lathe into a safe outlet that matches its power needs. Make sure all connections are tight and secure. Finally, test the lathe with no tools inside to see if it runs smoothly.

What Types Of Collets Are Commonly Used In Metal Lathes, And How Do Their Designs Affect Precision And Gripping Strength?In metal lathes, we commonly use three types of collets: parallel, tapered, and self-centering. Parallel collets grip tightly from the sides, making them great for holding small, precise pieces. Tapered collets fit snugly in a cone shape, which helps hold things securely and evenly. Self-centering collets grab the object from all sides at once, making them very precise. Each design helps keep your work steady and accurate while you cut metal.

What Are The Common Troubleshooting Steps For Electrical Issues In A Lathe Collet System, Particularly In Relation To Its Wiring Diagram?To fix electrical problems in a lathe collet system, we start by checking the wiring diagram. First, look for any loose or broken wires. Make sure all connections are tight and secure. Next, check for burned-out fuses or faulty switches. Finally, if everything looks good, try testing the power source to see if it works.

How Can You Create A Custom Wiring Diagram For A Lathe Collet System To Accommodate Specific Motor Types Or Control Systems?To create a custom wiring diagram for a lathe collet system, you need to know your motor type. First, look at the motor’s wires and how they connect. Then, draw a simple sketch showing how to connect them to the collet system. Make sure to include any control systems you use, like switches. Finally, check your diagram to ensure everything matches and makes sense.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Lathe Collet System And Wiring Diagrams For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe collet systems and wiring diagrams for metal lathes: 1. What is a lathe collet? A lathe collet holds a tool or part tightly while you work on it. 2. How do you switch tools in a lathe collet? You loosen the collet, change the tool, and then tighten it again. 3. Why is it important to use the right collet size? Using the right size keeps the tool secure and helps you work better. 4. What is a wiring diagram for a metal lathe? A wiring diagram shows how to connect the electrical parts of the lathe. 5. How can you find a good wiring diagram? You can check the user manual or look online for diagrams matching your lathe model.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Lathe Collet System, And How Do They Work Together To Secure Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe collet system has three main parts: the collet, the collet nut, and the spindle. The collet is a small sleeve that holds the workpiece tightly. You place the workpiece inside the collet, and then screw the collet nut onto it. This tightens everything, keeping the workpiece secure while the lathe spins it. Together, these parts make sure your material stays in place so you can shape or cut it safely.”}},{“@type”: “Question”,”name”: “How Do You Properly Wire The Electrical Components Of A Metal Lathe To Ensure Safe And Efficient Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe safely, first, turn off the power. Connect the wires to the motor, following the color codes. Then, plug the lathe into a safe outlet that matches its power needs. Make sure all connections are tight and secure. Finally, test the lathe with no tools inside to see if it runs smoothly.”}},{“@type”: “Question”,”name”: “What Types Of Collets Are Commonly Used In Metal Lathes, And How Do Their Designs Affect Precision And Gripping Strength?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathes, we commonly use three types of collets: parallel, tapered, and self-centering. Parallel collets grip tightly from the sides, making them great for holding small, precise pieces. Tapered collets fit snugly in a cone shape, which helps hold things securely and evenly. Self-centering collets grab the object from all sides at once, making them very precise. Each design helps keep your work steady and accurate while you cut metal.”}},{“@type”: “Question”,”name”: “What Are The Common Troubleshooting Steps For Electrical Issues In A Lathe Collet System, Particularly In Relation To Its Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix electrical problems in a lathe collet system, we start by checking the wiring diagram. First, look for any loose or broken wires. Make sure all connections are tight and secure. Next, check for burned-out fuses or faulty switches. Finally, if everything looks good, try testing the power source to see if it works.”}},{“@type”: “Question”,”name”: “How Can You Create A Custom Wiring Diagram For A Lathe Collet System To Accommodate Specific Motor Types Or Control Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create a custom wiring diagram for a lathe collet system, you need to know your motor type. First, look at the motor’s wires and how they connect. Then, draw a simple sketch showing how to connect them to the collet system. Make sure to include any control systems you use, like switches. Finally, check your diagram to ensure everything matches and makes sense.”}}]}