Have you ever tried to make a perfect cut on a lathe? It can be tricky! One key part that helps is the compound rest gib. You might wonder what a gib is and why it matters. Imagine trying to cut wood, but your tool keeps slipping. Frustrating, right?

The gib keeps things tight and secure. But sometimes, it gets loose. When that happens, adjustments are needed. Learning how to adjust the lathe compound rest gib can make a big difference. It’s like getting a magical tool that makes your work easier.

Did you know? Proper adjustments can lead to smoother cuts and better finishes. Wouldn’t it feel great to create something amazing with a little extra effort? Let’s dive into how to make those adjustments and improve your lathe experience!

Lathe Compound Rest Gib Adjustment: Essential Guide & Tips

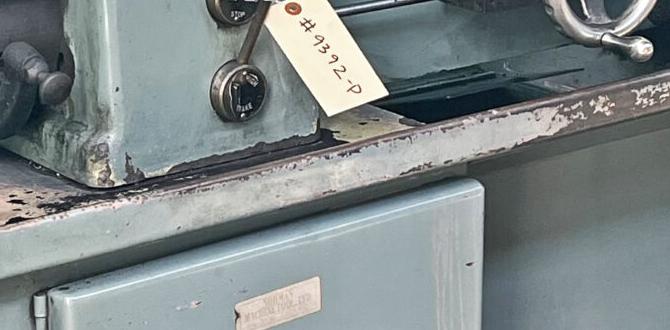

Lathe Compound Rest Gib Adjustment

Adjusting the lathe compound rest gib improves your machining accuracy. This involves tightening or loosening the gib to control movement. Have you ever noticed your tool slipping while cutting? It might be due to a loose gib. Keeping it adjusted helps your lathe work smoothly and efficiently. A well-maintained gib can even extend the life of your machine. Remember, regular checks can save you time and frustration in your projects!Understanding the Lathe Compound Rest

Definition and function of the compound rest. Importance of gib adjustment for precision machining.The compound rest is a vital part of a lathe. It helps you move the tool in different directions for making precise cuts. Without it, shaping metal or wood would be tough. The gib is a small piece that holds the compound rest in place. Adjusting the gib keeps everything snug. This ensures accuracy during machining, so parts fit together well. Even a small mistake can lead to big problems in your project.

Why is gib adjustment important?

Gib adjustment is crucial for precision. A loose gib can cause wobbling, leading to poor cuts. A well-adjusted gib helps tools move smoothly. It creates accurate shapes and sizes.

Key Points:

- The compound rest directs tool movement.

- The gib ensures stability and tightness.

- Proper adjustment improves accuracy.

Components of the Compound Rest

Detailed description of gib, slides, and related mechanisms. Role of each component in the functioning of the compound rest.The compound rest has important parts that help it work properly. One key part is the gib. It keeps everything steady. The slides allow smooth movement. Each piece connects securely, helping the tool move without wobbles. When these parts work well, they allow for precise cuts. Here’s how they function:

- Gib: Holds components tightly and reduces play.

- Slides: Facilitate easy, controlled movement.

- Related mechanisms: Ensure stability and accuracy during machining.

Why is gib adjustment important?

Adjusting the gib is vital because it helps limit any movement. This leads to better cutting accuracy and smooth operation. If not adjusted, the tool can become loose and hard to control.

Signs That Your Gib Needs Adjustment

Common indicators of poor gib adjustment. Impact of improper adjustment on machining accuracy.Are your machine parts playing hide and seek? If your lathe struggles to cut straight, it’s a sign that your gib may need adjustment. Common clues include awkward movement, strange noises, and becoming less precise. Improper adjustments can lead to more errors, making your projects cost more time and money. A well-adjusted gib helps keep everything smooth and accurate, so your machining stays top-notch. Remember, a little tweak can turn your troubles into triumphs!

| Signs Your Gib Needs Adjustment | Impact on Accuracy |

|---|---|

| Awkward Movement | Increased errors in cuts |

| Unusual Noises | Poor finishing on parts |

| Loss of Precision | Wasted materials and time |

Tools Required for Gib Adjustment

List of essential tools for effective adjustment. Safety equipment and best practices.To achieve a good gib adjustment, you need some handy tools. First, you should have a wrench for tightening bolts. A screwdriver is also important for adjusting screws. Don’t forget a level to check the balance. Finally, wear safety goggles and gloves to protect yourself. These tools help make your work safe and effective.

What tools do you need for gib adjustment?

You need wrenches, screwdrivers, a level, and safety goggles.

Step-by-Step Guide to Adjusting the Gib

Detailed procedure of adjusting the gibs on a lathe. Tips for ensuring smooth operation after adjustment.Adjusting the gibs on a lathe helps it work better. Here’s how to do it:

- First, clean the area around the gib.

- Loosen the gib screws slightly.

- Move the compound rest to check for tightness.

- Turn the screws until it’s snug but can still slide.

- Tighten the screws evenly.

For smooth operation:

- Regularly check and clean the gib.

- Use lubrication as needed.

- Inspect for wear on parts.

What is the importance of gib adjustment in a lathe?

Proper gib adjustment keeps the lathe parts aligned. This enhances accuracy and prevents wear. A well-adjusted gib makes cutting smoother and safer too.

Common Mistakes to Avoid During Adjustment

Typical errors made when adjusting the gib. How to prevent these errors for optimal performance.Adjusting the gib can feel like trying to balance a spoon on your nose—tricky business! Common mistakes include over-tightening, which can cause jams or wobbles. Instead of going Hulk on the knobs, loosen them just enough for smooth movement. Another blunder is forgetting to clean before adjusting. Dirt can mess everything up faster than a dog chasing its tail. Always check your levels and don’t skip any steps. Perfection takes patience, but it’s worth it!

| Error | Prevention |

|---|---|

| Over-tightening | Adjust gently and check movement. |

| Ignoring cleanliness | Always clean before adjustments. |

| Skipping steps | Follow the adjustment guide carefully. |

Maintaining Your Lathe for Optimal Performance

Tips for regular maintenance of the compound rest and gibs. Scheduling adjustments and inspections.Keeping your lathe in tip-top shape is crucial for great work. Start by checking the compound rest and the gibs regularly. A loose gouge leads to bad cuts, and nobody enjoys a wonky piece! Squeeze in a quick inspection every few weeks to catch any problems early. It’s easy—like checking if you have snacks before a movie! Here’s a simple schedule:

| Action | Frequency |

|---|---|

| Inspect the compound rest | Every 2 weeks |

| Adjust the gibs | Monthly |

| Clean and lubricate | Every 3 months |

Remember to keep your lathe well-oiled and clean. A tidy machine is a happy machine—just like a tidy room makes for a happy kid!

Additional Resources and References

Recommended books and articles on lathe maintenance. Online forums and communities for further assistance.Finding good resources can help with lathe maintenance. Here are a few recommendations:

- Books like “The Complete Guide to Lathes” offer great insights.

- Articles on machinery websites provide useful tips on maintenance.

Online forums can also help. You can connect with skilled workers. They share their knowledge and experiences. This is helpful for any questions you have about lathe compound rest gib adjustment.

Where can I find help with lathe maintenance?

Look for online communities and forums. These places can answer your questions and provide practical advice. Joining is easy, and many are friendly and eager to help.

Conclusion

In summary, adjusting the lathe compound rest gib helps you improve precision and control in your work. Regularly check and tighten the gib for better performance. If you need more guidance, look for videos or manuals that explain the process. Experiment with your lathe, and you’ll become more skilled over time. Keep learning and enjoy your projects!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Compound Rest Gib Adjustment:Sure! The compound rest is a part of a lathe machine that helps you cut materials. If it’s loose or too tight, you can adjust the gib, which is a piece that helps it slide smoothly. To do this, you need to turn some screws to change how tight the gib is. Be careful not to make it too tight, or it won’t move at all! Make small adjustments and test it until it feels just right.

Sure! Please go ahead and ask your question, and I’ll be happy to help.

What Is The Purpose Of The Gib Adjustment On A Lathe’S Compound Rest?The gib adjustment on a lathe’s compound rest helps you keep it tight and steady. This means you can move the tool accurately without any wobbles. If it gets too loose, you can adjust the gib to make it tighter. Being precise is important when you’re making things on the lathe.

How Can You Identify If The Gib Is Worn Or Requires Adjustment On A Compound Rest?To check if the gib is worn or needs adjustment, look for tight spots. Move the compound rest back and forth. If it feels rough or sticks, it might need help. You can also check for gaps between parts. If they are too big, it’s time for some adjustments.

What Are The Steps To Properly Adjust The Gib On A Lathe’S Compound Rest?To adjust the gib on a lathe’s compound rest, first, find the gib adjustment screws. These screws are usually near the moving part of the rest. Next, use a wrench to tighten or loosen these screws gently. Adjust until the rest moves smoothly but isn’t too loose. Finally, test the motion to make sure everything feels just right!

What Tools Are Typically Needed To Perform Gib Adjustments On A Lathe?To perform gib adjustments on a lathe, you typically need a few tools. First, you need a wrench to loosen or tighten bolts. A screwdriver is also important for adjusting screws. Sometimes, a feeler gauge helps check gaps. We may also use a small hammer for gentle tapping if needed.

How Can Improper Gib Adjustment Affect The Machining Accuracy And Precision Of A Lathe?If the gib adjustment is wrong on a lathe, it can make the machine move too much or not enough. This means the parts we make might not fit together well. We might end up with shapes that are not as perfect as we want. In short, bad adjustments can make our work less accurate and precise.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Compound Rest Gib Adjustment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The compound rest is a part of a lathe machine that helps you cut materials. If it’s loose or too tight, you can adjust the gib, which is a piece that helps it slide smoothly. To do this, you need to turn some screws to change how tight the gib is. Be careful not to make it too tight, or it won’t move at all! Make small adjustments and test it until it feels just right.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of The Gib Adjustment On A Lathe’S Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gib adjustment on a lathe’s compound rest helps you keep it tight and steady. This means you can move the tool accurately without any wobbles. If it gets too loose, you can adjust the gib to make it tighter. Being precise is important when you’re making things on the lathe.”}},{“@type”: “Question”,”name”: “How Can You Identify If The Gib Is Worn Or Requires Adjustment On A Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if the gib is worn or needs adjustment, look for tight spots. Move the compound rest back and forth. If it feels rough or sticks, it might need help. You can also check for gaps between parts. If they are too big, it’s time for some adjustments.”}},{“@type”: “Question”,”name”: “What Are The Steps To Properly Adjust The Gib On A Lathe’S Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the gib on a lathe’s compound rest, first, find the gib adjustment screws. These screws are usually near the moving part of the rest. Next, use a wrench to tighten or loosen these screws gently. Adjust until the rest moves smoothly but isn’t too loose. Finally, test the motion to make sure everything feels just right!”}},{“@type”: “Question”,”name”: “What Tools Are Typically Needed To Perform Gib Adjustments On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To perform gib adjustments on a lathe, you typically need a few tools. First, you need a wrench to loosen or tighten bolts. A screwdriver is also important for adjusting screws. Sometimes, a feeler gauge helps check gaps. We may also use a small hammer for gentle tapping if needed.”}},{“@type”: “Question”,”name”: “How Can Improper Gib Adjustment Affect The Machining Accuracy And Precision Of A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the gib adjustment is wrong on a lathe, it can make the machine move too much or not enough. This means the parts we make might not fit together well. We might end up with shapes that are not as perfect as we want. In short, bad adjustments can make our work less accurate and precise.”}}]}