Have you ever looked at a lathe and wondered how it works? One important part is the lathe compound rest locking mechanism. This small but mighty tool helps lock the compound rest in place. Without it, your work could go off course.

Imagine trying to carve a beautiful wooden bowl. If your tool moves unexpectedly, that bowl may end up as firewood! That’s why the lathe compound rest locking mechanism is so important. It keeps everything steady and helps you make precise cuts.

Here’s a fun fact: Did you know that the first lathes date back thousands of years? They have evolved a lot, but the locking mechanism remains key to good craftsmanship. So, let’s dive deeper into how this mechanism works and why it matters!

Understanding The Lathe Compound Rest Locking Mechanism

Understanding the Lathe Compound Rest Locking Mechanism

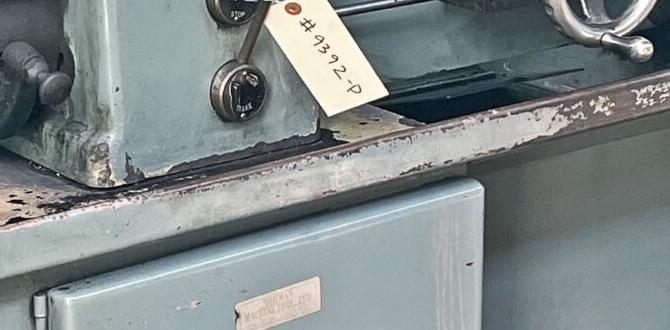

The lathe compound rest locking mechanism plays a crucial role in precision machining. This mechanism secures the compound rest, allowing accurate adjustments during turning operations. Have you ever wondered how some machinists achieve such detailed finishes? The secret lies in properly locking the compound rest. By understanding how to use this locking feature, you can enhance your projects and avoid mistakes. Remember, a well-secured compound rest is key to successful machining!Importance of the Locking Mechanism

Role of the locking mechanism in maintaining precision and accuracy. Impact on machining quality and overall productivity.The locking mechanism on a lathe is like the glue that holds everything together. It keeps the compound rest stable, which is essential for precision and accuracy. Without it, your measurements could be as wobbly as a three-legged chair! When the mechanism is working well, it helps improve machining quality and boosts productivity. Who doesn’t want to be faster and better? So, make sure you keep that lock tight!

| Role of Locking Mechanism | Impact on Quality | Effect on Productivity |

|---|---|---|

| Secures the compound rest | Ensures accurate cuts | Saves time in setup |

| Prevents movement | Reduces errors | Increases output |

| Enhances stability | Improves finish quality | Optimizes workflow |

How to Maintain a Lathe Compound Rest Locking Mechanism

Routine maintenance practices to ensure optimal function. Signs of wear and how to troubleshoot common issues.To keep your lathe compound rest locking mechanism working well, regular maintenance is key. Check for signs of wear, like rust or poor movement. Cleaning and oiling can help prevent problems. If you notice any issues, try tightening loose parts or replacing worn-out pieces. Here are some tips:

- Clean it often.

- Oil moving parts regularly.

- Look for rust or damage.

- Tighten screws and bolts.

Staying on top of these tasks keeps your lathe in good shape!

What are common signs of wear in a lathe locking mechanism?

Common signs include unusual noise, difficulty locking, and visible rust. Regular checks can help you catch these issues early.

Upgrading Your Lathe Compound Rest Locking Mechanism

Factors to consider when looking for upgrades. Recommended brands and products available in the market.Upgrading your lathe’s locking mechanism can improve its performance. Consider these key factors:

- Compatibility: Ensure it fits your lathe model.

- Durability: Look for strong materials that last.

- Ease of Use: Choose a design that’s simple to operate.

Some recommended brands include:

- Grizzly: Known for reliable tools.

- Jet: Offers solid upgrades.

- Delta: Provides a range of accessories.

How do I choose the right lathe locking mechanism?

Focus on what fits your machine best. Think about the strength and ease of use. Check reviews to see how they perform in real life.

Common Problems and Solutions with Lathe Compound Rest Locking Mechanisms

Discussion of frequent issues faced by machinists. Practical solutions and tips for resolving these problems.Many machinists face problems with lathe compound rest locking mechanisms. Common issues include difficulty in locking the rest, misalignment, and wear over time. Here are some practical solutions:

- Check the screws. Sometimes they are loose and need tightening.

- Clean the locking mechanism. Dirt can prevent it from working well.

- Replace worn parts. If a part is damaged, the system will not lock properly.

By solving these issues, machinists can ensure smoother operations and better results.

What is the most common issue with lathe compound rest locking mechanisms?

The most common issue is difficulty in locking the rest. This often happens due to dirt or loose screws.

Real-World Applications of Lathe Compound Rest Locking Mechanisms

Examples of industries that rely on lathe machines. Case studies demonstrating the importance of effective locking mechanisms.Many industries depend on lathe machines. These machines help shape metal and wood pieces into precise parts. Imagine a car factory making engine parts. They need lathe machines and reliable locking mechanisms to create safe and high-quality pieces. Here are a few key sectors:

- Aerospace

- Automotive

- Construction

- Furniture production

In each case, effective locking is crucial. For instance, in custom car parts, tight tolerances mean even a small mistake can lead to failure. A solid lathe compound rest locking mechanism prevents this issue and ensures safety and precision.

Why are locking mechanisms important?

Locking mechanisms keep the tool steady and accurate. They prevent movement that could ruin a piece. This ensures that every part is made just right for its purpose.

Expert Tips for Machinists

Best practices for using the locking mechanism effectively. Innovations and advancements in lathe technology related to locking mechanisms.Using the locking mechanism properly can improve your machining. Here are some best practices:

- Keep it clean: Dirt can make locking harder.

- Tighten well: A firm lock prevents movement.

- Check regularly: Make sure it’s functioning every time you use it.

- Use updates: New tools can make locking easier and safer.

Advancements in lathe technology continue to change the game. These improvements make it easier for machinists to achieve precision. Some innovations include automatic locking mechanisms and digital controls. These help create a safer and more efficient workspace.

What are the best tips for using a lathe’s locking mechanism?

Use a firm grip, maintain tools, and choose modern solutions to enhance safety and ease.

Conclusion

In summary, the lathe compound rest locking mechanism is essential for precision work. It keeps the tool steady and accurate while you’re machining. Understanding how it works helps you achieve better results. You can practice using it on your lathe. For more tips and details, consider reading further or watching tutorial videos to improve your skills. Happy turning!FAQs

Sure! Here Are Five Questions Related To The Lathe Compound Rest Locking Mechanism:What is a lathe compound rest? A lathe compound rest is part of a machine tool. It helps hold and move the tool when shaping metal or wood. It allows for different angles and adjustments. This makes it easier to cut materials smoothly. How does the locking mechanism work? The locking mechanism keeps the compound rest in place. You can turn a lever or tighten a screw. This stops the part from moving while you work. It’s important for making precise cuts. Why is it important to lock the compound rest? Locking the compound rest is important for safety and accuracy. If it moves while cutting, it can mess up your work. It also helps prevent accidents. So, always remember to lock it when you finish adjusting! When should you unlock the compound rest? You should unlock the compound rest when you need to change the angle or position. Before starting work, make sure it’s locked. Unlock it only when you’re ready to move it. How do you know if the locking mechanism is working? You can check if the locking mechanism is working by trying to move the compound rest. If it doesn’t move, it’s locked properly. If it feels loose, you may need to tighten it. Always test it before you start cutting!

Sure! Please provide the question you’d like me to answer.

What Is The Primary Function Of The Locking Mechanism In A Lathe Compound Rest?The locking mechanism in a lathe compound rest holds the part steady. When you lock it, it stops moving. This way, you can cut or shape materials safely. If it wasn’t locked, the part might shift while you’re working. So, it helps you work better and more accurately!

How Does The Locking Mechanism Impact The Precision And Stability Of Machining Operations On A Lathe?The locking mechanism on a lathe keeps the parts in place while you work. When everything is held tightly, it helps make your cuts very smooth and even. If the parts move around, your work might become wobbly or uneven. So, a good locking system helps us be more accurate and steady when we’re shaping things on the lathe.

What Are The Common Types Of Locking Mechanisms Used In Lathe Compound Rests?Common types of locking mechanisms used in lathe compound rests include handles, levers, and screws. Handles let you turn and secure the rest in place. Levers are easy to push or pull for quick adjustments. Screws are turned to tightly hold the rest where you want it. Each mechanism helps keep the parts steady while you work.

How Can Improper Adjustment Or Failure Of The Locking Mechanism Affect The Performance Of A Lathe?If the locking mechanism on a lathe is not set right, it can cause problems. The lathe may wobble when it spins. This can make things uneven and hard to work with. If the parts aren’t secure, we could get hurt or break things. It’s important to check the locking mechanism to keep everything safe and working well.

What Maintenance Practices Can Be Implemented To Ensure The Locking Mechanism Of A Lathe Compound Rest Operates Effectively?To keep the locking mechanism of a lathe compound rest working well, you should clean it regularly. Use a soft cloth to remove dust and grime. Check the screws and bolts to make sure they’re tight. You can also apply a little oil to help it move smoothly. Always test it after cleaning to ensure it locks and unlocks easily.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Lathe Compound Rest Locking Mechanism:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “What is a lathe compound rest? A lathe compound rest is part of a machine tool. It helps hold and move the tool when shaping metal or wood. It allows for different angles and adjustments. This makes it easier to cut materials smoothly. How does the locking mechanism work? The locking mechanism keeps the compound rest in place. You can turn a lever or tighten a screw. This stops the part from moving while you work. It’s important for making precise cuts. Why is it important to lock the compound rest? Locking the compound rest is important for safety and accuracy. If it moves while cutting, it can mess up your work. It also helps prevent accidents. So, always remember to lock it when you finish adjusting! When should you unlock the compound rest? You should unlock the compound rest when you need to change the angle or position. Before starting work, make sure it’s locked. Unlock it only when you’re ready to move it. How do you know if the locking mechanism is working? You can check if the locking mechanism is working by trying to move the compound rest. If it doesn’t move, it’s locked properly. If it feels loose, you may need to tighten it. Always test it before you start cutting!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Locking Mechanism In A Lathe Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The locking mechanism in a lathe compound rest holds the part steady. When you lock it, it stops moving. This way, you can cut or shape materials safely. If it wasn’t locked, the part might shift while you’re working. So, it helps you work better and more accurately!”}},{“@type”: “Question”,”name”: “How Does The Locking Mechanism Impact The Precision And Stability Of Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The locking mechanism on a lathe keeps the parts in place while you work. When everything is held tightly, it helps make your cuts very smooth and even. If the parts move around, your work might become wobbly or uneven. So, a good locking system helps us be more accurate and steady when we’re shaping things on the lathe.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Locking Mechanisms Used In Lathe Compound Rests?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common types of locking mechanisms used in lathe compound rests include handles, levers, and screws. Handles let you turn and secure the rest in place. Levers are easy to push or pull for quick adjustments. Screws are turned to tightly hold the rest where you want it. Each mechanism helps keep the parts steady while you work.”}},{“@type”: “Question”,”name”: “How Can Improper Adjustment Or Failure Of The Locking Mechanism Affect The Performance Of A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the locking mechanism on a lathe is not set right, it can cause problems. The lathe may wobble when it spins. This can make things uneven and hard to work with. If the parts aren’t secure, we could get hurt or break things. It’s important to check the locking mechanism to keep everything safe and working well.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Be Implemented To Ensure The Locking Mechanism Of A Lathe Compound Rest Operates Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the locking mechanism of a lathe compound rest working well, you should clean it regularly. Use a soft cloth to remove dust and grime. Check the screws and bolts to make sure they’re tight. You can also apply a little oil to help it move smoothly. Always test it after cleaning to ensure it locks and unlocks easily.”}}]}