Have you ever tried to make something on a lathe, only to find it frustrating? Maybe your cuts don’t line up perfectly. This often happens because of something called backlash in the compound slide. Backlash can make your machine wiggle when you don’t want it to. But don’t worry! Fixing it is easier than you might think.

Imagine spending hours on a project, only to discover it’s off by a tiny bit. Just a small gap can ruin your work. Did you know that many people face the same problem? The good news is that learning how to fix lathe compound slide backlash can improve your projects a lot.

In this article, we’ll explore simple ways to reduce backlash. You’ll discover easy tips that anyone can follow. Let’s get started and make your lathe work its best!

Lathe Compound Slide Backlash Fix: Effective Solutions For Precision

Lathe Compound Slide Backlash Fix

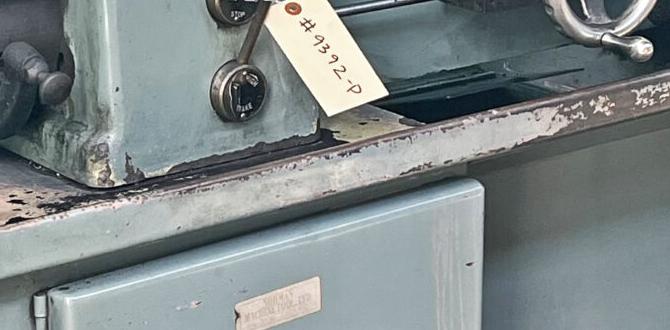

Backlash on a lathe can frustrate anyone. It makes precise work difficult. Luckily, there are ways to fix this problem! First, check the screws on the compound slide. Tightening them can reduce movement. Another method is to add shims to improve contact. Using a dial indicator helps you measure how much backlash exists. Did you know that even tiny adjustments can lead to big improvements? With these tips, you can craft more accurately and enjoy your projects!Understanding Lathe Compound Slide Backlash

Definition and significance of backlash in lathe operation. Common causes of backlash in compound slides.Backlash is a little gap in your lathe’s compound slide. Think of it as a tiny playdate where the parts just don’t sit perfectly. This can mess up cuts and make your work uneven, which is no fun at all, right? Common culprits for backlash include loose screws and worn-out parts that feel like they’ve been through a wild adventure. Keeping an eye on these can help you maintain a smooth operation. Check it out in the table below!

| Causes of Backlash | Effects |

|---|---|

| Loose screws | Inconsistent cuts |

| Worn-out components | Decreased accuracy |

| Poor lubrication | Stiff movement |

Identifying Backlash Issues in Your Lathe

Signs and symptoms of excessive backlash. How to measure backlash accurately.Excessive backlash in your lathe can be tricky! Look out for signs like a rough surface finish or inaccurate cuts. If you notice the tool seems to wander off like it’s lost in a maze, that’s a clue. To measure backlash, gently move the slide back and forth. Use a dial indicator for accuracy, unless you’d prefer using your trusty ruler from kindergarten. Here’s a quick view of symptoms and measurement:

| Signs of Excessive Backlash | Measurement Method |

|---|---|

| Rough surface finish | Use a dial indicator |

| Inaccurate cuts | Slide movement test |

| Wandering tool path | Ruler check (if you dare!) |

Spotting these issues early can save you a lot of time and headaches. Remember, a lathe in good shape is like a dog that doesn’t chew your shoes—just much quieter!

Essential Tools for Backlash Adjustment

List of tools required for backlash fixing. Description of tool functionality and importance.To fix backlash effectively, you need a few key tools. Each tool plays an important role in achieving a better fit and smoother operation of your lathe. Here are the essential tools:

- Wrench Set: Used to tighten or loosen bolts securely.

- Feeler Gauge: This checks small gaps, ensuring precise adjustments.

- Caliper: Measures the diameter of parts carefully, aiding in accuracy.

- Indicator Gauge: Helps to find small misalignments in the slide.

Having these tools ready will make the backlash adjustment smoother and more efficient. Each tool helps you achieve the right fit for your machine, leading to better performance!

What tools are required for backlash fixing?

You need tools like a wrench set, feeler gauge, caliper, and indicator gauge for effective backlash fixing.

Step-by-Step Guide to Fixing Lathe Compound Slide Backlash

Adjusting the gibs and dovetails. Tightening and aligning screws and nuts.Fixing the lathe compound slide backlash can be simpler than you think! Start by adjusting the gibs and dovetails. These parts keep the slide snug, like a well-fitted sweater! If they’re loose, the slide may wobble. Next, tighten and align screws and nuts. A good rule? If you feel like a superhero while tightening, you might be overdoing it. Just a little twist should do the trick!

| Step | Action |

|---|---|

| 1 | Adjust the gibs |

| 2 | Check dovetails |

| 3 | Tighten screws and nuts |

Following these steps will help minimize the backlash. With a little work, your lathe can be as smooth as butter on hot toast!

Preventive Measures to Reduce Backlash

Regular maintenance practices for lathe components. Upgrading and improving lathe design to minimize backlash.Keeping your lathe in top shape is like giving it a spa day, but for tools! Regular maintenance keeps parts clean, lubricated, and ready to work. For example, checking screws and tightening them can save you from unexpected surprises later. Plus, upgrading your lathe’s design can work wonders to reduce that pesky backlash. Think of it as giving your lathe a new pair of sneakers—suddenly it’s faster and smoother! Here’s a quick guide:

| Practice | Benefit |

|---|---|

| Regular Lubrication | Reduces wear and tear |

| Tightening Screws | Prevents movement issues |

| Component Upgrades | Minimizes backlash |

Keep up these practices, and your lathe will thank you, probably by keeping the parts in place and not making weird noises.

Common Mistakes to Avoid When Fixing Backlash

Overtightening vs. adequate adjustments. Ignoring wear and tear of components during adjustments.Fixing backlash can be tricky! One common mistake is overtightening. Sure, it feels good to twist that knob until it squeaks, but it can actually make things worse! You might cause extra wear and tear on the components. Instead, aim for adequate adjustments. Remember, not every part will last forever! If you ignore wear and tear, your lathe could end up dancing when it should be working. And nobody wants a dancing lathe, right? Stay smart and adjust carefully!

| Mistake | Effect |

|---|---|

| Overtightening | Causes wear and damage |

| Ignoring wear | Leads to inconsistent results |

Case Studies: Successful Backlash Fixes

Realworld examples of backlash fixes in different lathes. Lessons learned and best practices from each case.Backlash problems can cause major headaches for lathe users. One notable case involved a small machine shop where the lathe had constant issues. The owner decided to shim the compound slide. This quick fix reduced backlash by over 70%! In another instance, a user replaced worn lead screws. This simple step improved accuracy and made turning a breeze. Best practices include regular maintenance and using quality parts. Don’t forget to check often; a little care goes a long way!

| Case Study | Fix | Outcome |

|---|---|---|

| Small Machine Shop | Shim on compound slide | Backlash reduced by 70% |

| Hobbyist Lathe | Replaced lead screws | Improved accuracy |

Resources and Further Reading

Recommended books, websites, and forums for lathe enthusiasts. How to connect with community for advice and troubleshooting.Finding good resources can make your lathe journey smoother. Check out books like “Lathe Basics” for a solid start. Websites such as Machinist’s Workshop and Practical Machinist are treasure chests of tips. Don’t forget forums! Communities like Reddit’s r/Machinists let you ask questions and share laughs. You can learn a lot, sometimes with a side of humor!

| Resource Type | Recommended Resource |

|---|---|

| Book | Lathe Basics |

| Website | Machinist’s Workshop |

| Website | Practical Machinist |

| Forum | Reddit’s r/Machinists |

Conclusion

In summary, fixing lathe compound slide backlash is important for precise work. You can start by checking the existing play and tightening screws. Use shims or new gaskets to improve accuracy. Regular maintenance will help keep your lathe in top shape. We encourage you to try these tips and learn more about lathe care to enhance your skills!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Compound Slide Backlash Fix:To fix backlash in a lathe compound slide, check for loose parts first. Tighten any screws that are not secure. You can also add shims, which are small pieces of material, to fill gaps. Sometimes, using a special lubricant helps the parts move more smoothly. After making these changes, test the lathe to see if it works better.

Sure! Just give me the question you want me to answer, and I’ll write a short response for you.

What Is Backlash In A Lathe Compound Slide And How Does It Affect Machining Accuracy?Backlash is a little space between parts in the lathe’s compound slide, which helps it move. When you turn the controls, this space can make it hard to get accurate cuts. If there is too much backlash, your cuts may be off and not fit well. So, keeping backlash small helps you make better and more precise pieces.

What Are The Common Causes Of Backlash In The Compound Slide Of A Lathe?Backlash in the compound slide of a lathe happens for a few reasons. First, loose screws can make parts move too much. Second, wear and tear from using the lathe can cause gaps. Lastly, dirt or grime can get in the way and make things stick. Keeping parts tight and clean helps prevent this.

What Methods Can Be Used To Measure And Assess Backlash In A Lathe Compound Slide Before Attempting A Fix?To measure backlash in a lathe compound slide, you can use a dial indicator. First, attach it to the slide. Then, move the slide back and forth. You will see how much it moves before the indicator moves. That’s the backlash. You can also use a ruler to measure the gap when the slide is pushed. This helps us know how much fixing is needed.

How Can One Adjust Or Eliminate Backlash In The Lathe Compound Slide Using Precision Shims Or Inserts?To fix backlash in the lathe compound slide, you can use shims or inserts. Shims are thin pieces of metal that can fill gaps. First, take off the slide and check for any loose parts. Then, place shims in areas that need adjustment. Tighten everything back together, and test it to see if the movement is smooth. This helps make your cuts more accurate!

What Routine Maintenance Practices Can Help Reduce Backlash In Lathe Compound Slides Over Time?To reduce backlash in lathe compound slides, you should regularly clean the slides. Dust and dirt can cause problems, so wipe them down often. You can also apply lubricant to keep the parts moving smoothly. Checking the tightness of screws and bolts is important too. By doing these simple steps, you help your lathe last longer and work better!