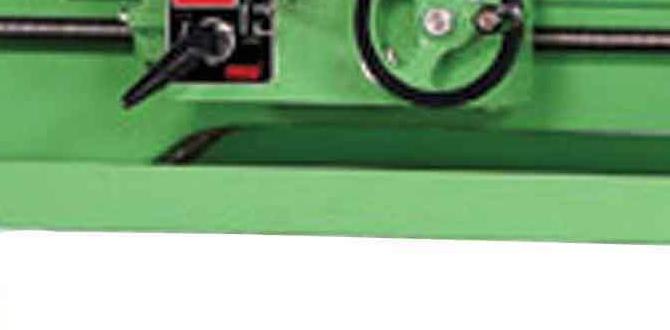

Have you ever wondered how machines can make tasks easier? Imagine turning a basic metal lathe into a smart, automated tool. It’s like giving your old toy a cool new upgrade! Lathe conversion is the process that lets you transform your manual lathe into an automated metal lathe.

This upgrade can save time and improve precision. Who wouldn’t want a machine that does the work while you relax? Picture a lathe that can work on its own, following your commands perfectly.

Many hobbyists are discovering the wonders of automation. With just a few changes, they can make their metal lathes do amazing tasks. Think about the creativity it opens up! What would you create if your machine could work faster and more accurately?

In this article, we will explore lathe conversion steps and benefits. You’ll learn how to make your metal lathe automated and the fun possibilities it brings. Get ready to dive into the exciting world of lathe automation!

Lathe Conversion: Metal Lathe Automation Made Easy

Lathe Conversion: Metal Lathe Automation

Transforming a regular lathe into an automated metal lathe opens doors to exciting possibilities. Imagine crafting precise parts without spending hours at the machine! This conversion allows for improved efficiency and consistency in projects. With automation, even beginners can achieve professional results. Did you know that automating a lathe can save you up to 50% on production time? By learning about lathe conversion, you unlock the potential to take your metalworking skills to new heights.Understanding Lathe Conversions

Definition and purpose of lathe conversion.. Benefits of converting a manual lathe to an automated system..Lathe conversion means changing a manual lathe into an automatic one. Why do this? Well, it makes work easier and faster! Imagine cutting shapes without sweating over your machine—sounds dreamy, right? With automation, you can work with precision, reduce errors, and even relax a bit while your lathe does the hard work. It’s like having your very own robot assistant! Here’s a quick table of benefits:

| Benefit | Description |

|---|---|

| Increased Efficiency | Finish tasks quicker. |

| Improved Accuracy | Get exact shapes every time. |

| Less Physical Effort | Let the machine do the heavy lifting. |

Essential Components for Automation

Key parts needed for converting a metal lathe.. Importance of precision components for effective automation..To automate a metal lathe effectively, you’ll need key parts. These components ensure everything runs smoothly and accurately. Precision is vital for great results. If the parts aren’t right, the automation won’t work as it should. Here are essential components:

- Stepper motors

- Controller board

- Power supply

- Linear actuators

- Feedback sensors

Each part plays a special role. They must fit together seamlessly to make sure the lathe operates perfectly. Remember, quality matters!

What are the essential components needed for automation?

Essential components include stepper motors, controller boards, power supplies, linear actuators, and feedback sensors. These parts work together to ensure precise automation of a metal lathe.

Step-by-Step Guide to Converting Your Lathe

Detailed process of conversion from manual to automated.. Safety measures to consider during the conversion process..Converting a manual lathe to an automated one is a fun project! First, gather your tools and parts. You’ll need a motor, controller, and some wires. Remember to always wear safety goggles. Safety first! Double-check all connections to avoid any shocking surprises—yikes! Create a clear plan. Then, carefully remove the manual parts and replace them with automated ones. Once done, test it out. If all goes well, you might just have a lathe that makes magic happen.

| Step | Description |

|---|---|

| 1 | Gather Tools |

| 2 | Wear Safety Gear |

| 3 | Remove Manual Parts |

| 4 | Install Automation Parts |

| 5 | Test the New Setup |

Software and Controls for Lathe Automation

Recommended software for programming automated lathes.. Discussion on user interfaces and control systems..Many cool programs can help control automated lathes. Software like Mach3 and LinuxCNC make your lathe dance to your tune! They are user-friendly, even for those who think coding is a foreign language.

Good controls let you watch your lathe perform magic while sipping coffee. It’s like having a robot buddy! The screens are colorful and simple, making it easy to adjust settings. Think of them as the GPS for your machining journey!

| Software | Key Features |

|---|---|

| Mach3 | Great for CNC, lots of support |

| LinuxCNC | Free and super customizable |

| Fusion 360 | Design and machining together |

Choosing the right software is like picking your favorite pizza toppings – everyone has a preference! Finding the best fit will make your metal lathe adventure smooth and fun.

Common Challenges and Solutions in Lathe Conversions

Typical obstacles in the conversion process.. Solutions and tips to overcome these challenges..Lathe conversions have some common hurdles. Builders often face parts misalignment, which can lead to errors. Another issue is software compatibility. Older machines may not work with new tech. However, there are easy ways to tackle these problems. First, ensure all parts fit before starting the conversion. Second, update software or choose compatible options. Follow these tips to make your conversion smoother.

- Check for part alignment.

- Update your software.

- Use trusted replacement parts.

What are the typical problems in lathe conversions?

Typical problems include misalignment, hardware compatibility, and software issues.How can I solve these problems?

To solve these problems, ensure correct alignments, upgrade your software, and use compatible parts.Maintenance Tips for Automated Lathes

Essential maintenance practices to ensure longevity.. Common issues and how to fix them..Keeping your automated lathe in good shape is key to making it last. Start with cleaning the machine regularly. Dust and grime can make it work poorly. Always check the oil levels. Low oil leads to big problems. Tighten loose parts to prevent them from breaking. Watch for strange noises; they could mean trouble.

- Change oil every 100 hours.

- Inspect belts monthly.

- Calibrate settings each week.

By following these tips, you can enjoy smooth operation and avoid costly repairs.

What are common issues with automated lathes?

Common problems include overheating, worn-out belts, and improper calibration. Overheating happens if there isn’t enough oil. Worn belts can slip. Calibration issues lead to inaccurate cuts.

Future Trends in Lathe Automation

Insights into emerging technologies in metal lathe automation.. Predictions for the future of lathe conversions in manufacturing..New technologies are changing metal lathe automation. These advancements make machines smarter and faster. Here are some trends to watch:

- Robotics: Robots help operate lathes efficiently.

- AI: Artificial intelligence analyzes data to improve processes.

- 3D Printing: This allows for layered manufacturing, changing how parts are made.

In the future, lathe conversions will become easier. Companies will embrace automation to boost productivity. This shift can lead to better quality and less waste. Overall, staying updated on these changes is crucial for manufacturers.

How will lathe automation change manufacturing?

Lathe automation will increase efficiency and reduce costs. Automated lathes will perform tasks faster than manual machines. This will help companies produce higher-quality items.

Conclusion

In conclusion, lathe conversion can transform standard lathes into automated metal lathes. This process improves efficiency and precision in your projects. You can learn to automate your lathe for better results. Explore upgrading your tools and techniques. Start small, gather information, and reach new heights in your metalworking journey. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Conversion For Metal Lathe Automation:Sure! Lathes are machines that turn metal into shapes. You can change a regular lathe into an automated one. This makes it easier to work without using your hands all the time. Automation helps to make things faster and more accurate. It’s like having a robot help you with your metal projects!

Sure! Please provide the question you would like me to answer.

What Are The Key Components Needed To Automate A Manual Metal Lathe For Enhanced Precision And Efficiency?To automate a manual metal lathe, you need a few key parts. First, get a computer or control system to run the machine. Then, use sensors to help measure how things are going. Motors are important too, as they move the lathe parts automatically. Lastly, a power source gives energy to run everything smoothly.

How Can Cnc (Computer Numerical Control) Technology Be Integrated Into An Existing Manual Metal Lathe Conversion?To change a manual metal lathe into a CNC (Computer Numerical Control) machine, you start by adding special parts. First, you need motors that can move the lathe’s tools. Then, you will install a computer that tells the motors what to do. Finally, connect the computer to the motors so they can work together. This way, you can control the lathe with precise commands!

What Are The Advantages And Disadvantages Of Converting A Manual Metal Lathe To An Automated System?Converting a manual metal lathe to an automated system has good and bad points. On the plus side, automation can make work faster and more precise. You can save time and produce better parts. However, it can also cost a lot of money to set up. Plus, if something breaks, it may be harder to fix than a manual lathe.

What Safety Considerations Should Be Taken Into Account When Automating A Metal Lathe?When we automate a metal lathe, we need to think about safety first. Always wear safety goggles to protect your eyes from flying pieces. Make sure to keep your hands away from moving parts. It’s also important to have an emergency stop button ready. Lastly, keep the work area clean and organized to prevent accidents.

How Does The Cost Of Conversion For Automation Compare To Purchasing A New Fully Automated Metal Lathe?Converting an old machine to be automatic can cost a lot of money. Sometimes, it’s cheaper than buying a brand new, fully automated metal lathe. But new machines usually work better and last longer. You have to think about how much money you want to spend and what you need the machine to do. In the end, it’s about finding what works best for you.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Conversion For Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathes are machines that turn metal into shapes. You can change a regular lathe into an automated one. This makes it easier to work without using your hands all the time. Automation helps to make things faster and more accurate. It’s like having a robot help you with your metal projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Needed To Automate A Manual Metal Lathe For Enhanced Precision And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To automate a manual metal lathe, you need a few key parts. First, get a computer or control system to run the machine. Then, use sensors to help measure how things are going. Motors are important too, as they move the lathe parts automatically. Lastly, a power source gives energy to run everything smoothly.”}},{“@type”: “Question”,”name”: “How Can Cnc (Computer Numerical Control) Technology Be Integrated Into An Existing Manual Metal Lathe Conversion?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change a manual metal lathe into a CNC (Computer Numerical Control) machine, you start by adding special parts. First, you need motors that can move the lathe’s tools. Then, you will install a computer that tells the motors what to do. Finally, connect the computer to the motors so they can work together. This way, you can control the lathe with precise commands!”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Converting A Manual Metal Lathe To An Automated System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Converting a manual metal lathe to an automated system has good and bad points. On the plus side, automation can make work faster and more precise. You can save time and produce better parts. However, it can also cost a lot of money to set up. Plus, if something breaks, it may be harder to fix than a manual lathe.”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account When Automating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we automate a metal lathe, we need to think about safety first. Always wear safety goggles to protect your eyes from flying pieces. Make sure to keep your hands away from moving parts. It’s also important to have an emergency stop button ready. Lastly, keep the work area clean and organized to prevent accidents.”}},{“@type”: “Question”,”name”: “How Does The Cost Of Conversion For Automation Compare To Purchasing A New Fully Automated Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Converting an old machine to be automatic can cost a lot of money. Sometimes, it’s cheaper than buying a brand new, fully automated metal lathe. But new machines usually work better and last longer. You have to think about how much money you want to spend and what you need the machine to do. In the end, it’s about finding what works best for you.”}}]}