Have you ever wondered how metal parts are made in a workshop? Imagine a tool that can shape and cut metal with precision. That’s where a lathe comes in. A lathe is a powerful machine that spins metal to create different shapes.

But what if you could make your own metal lathe? Many enthusiasts choose to do a lathe conversion. This process allows them to upgrade their machines for better performance. It’s like giving your favorite toy a cool upgrade!

One key aspect of this conversion is the gear train. The gear train affects how the lathe operates. It helps control speed and torque, making it crucial for smooth running. Understanding this part can seem tricky. But it opens up a world of possibilities for custom projects!

Get ready to explore the exciting world of lathe conversion and gear trains. You might just find yourself inspired to start your own project!

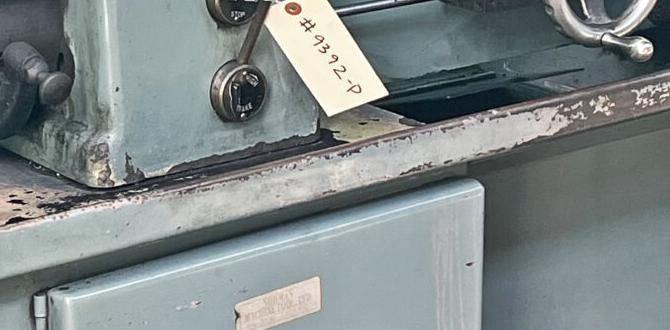

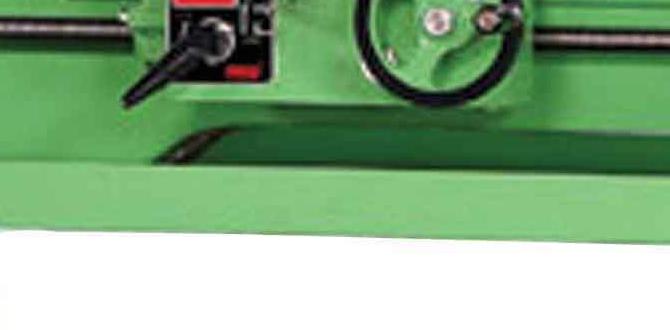

Lathe Conversion: Upgrading Metal Lathe Gear Train Systems The World Of Machining Continues To Evolve, And Many Hobbyists And Professionals Are Exploring The Benefits Of Lathe Conversion. In Particular, Upgrading A Metal Lathe Gear Train Can Significantly Enhance Productivity And Precision. Here’S A Comprehensive Guide On How To Approach Your Lathe Conversion Project Effectively. Understanding Lathe Conversion Lathe Conversion Refers To Modifying Or Upgrading Existing Lathe Machines To Improve Their Functionality, Efficiency, Or Capabilities. This May Involve Integrating New Components, Like A Gear Train, Enabling A Range Of Speeds And Torque To Adapt To Various Machining Tasks. Gear Trains In Metal Lathes Play A Crucial Role In Controlling The Lathe’S Feed Mechanism And Spindle Speed, Making Them Critical For Precision Work. Benefits Of Upgrading Gear Trains 1. **Increased Precision**: Upgraded Gear Trains Can Provide Improved Control Over Spindle Speeds, Leading To More Accurate Cuts. 2. **Enhanced Versatility**: By Converting The Lathe With A New Gear Train, You Can Handle A Wider Array Of Materials And Projects. 3. **Improved Efficiency**: A Well-Designed Gear Train Can Enhance The Machine’S Overall Performance And Reduce Wear And Tear. Choosing The Right Gear Train For Your Metal Lathe When Selecting A Gear Train For Your Lathe Conversion, Consider The Following Factors: – **Compatibility**: Ensure The Gear Train Is Compatible With Your Specific Lathe Model. – **Material**: Opt For Durable Materials That Can Withstand Prolonged Use. – **Gear Ratios**: Select Gear Ratios That Align With The Kind Of Work You Intend To Perform. Steps For Lathe Conversion 1. **Assess Your Current Lathe**: Identify The Components That Require Upgrades And Determine The Feasibility Of The Conversion. 2. **Select Gear Train Components**: Based On Your Assessment, Choose The Appropriate Gears, Bearings, And Other Necessary Parts. 3. **Disassemble The Lathe**: Carefully Take Apart Your Lathe, Documenting Each Step To Make Reassembly Easier. 4. **Install The New Gear Train**: Follow Your Manufacturer’S Guidelines Or A Reliable Tutorial To Install The New Components Accurately. 5. **Test The Setup**: Once Reassembled, Run Tests To Ensure That The Machine Operates Smoothly And As Expected. Final Thoughts Upgrading Your Metal Lathe Gear Train Is An Excellent Way To Breathe New Life Into An Existing Machine. With The Right Approach And Careful Planning, Lathe Conversion Can Yield Remarkable Improvements In Performance, Precision, And Versatility. Whether You’Re A Hobbyist Or A Professional Machinist, This Enhancement Can Significantly Impact Your Projects.

Lathe Conversion: Metal Lathe Gear Train

Are you ready to transform your lathe into a high-performance tool? With a metal lathe gear train conversion, you can enhance your machine’s capabilities. This upgrade improves precision and efficiency for various projects. Did you know that a well-designed gear train helps distribute power better? This means smoother operation and longer-lasting tools. Understanding the components and their functions can make all the difference. Get ready to take your lathe work to the next level!Understanding Lathe Conversions

Definition and purpose of lathe conversion. Benefits of converting a lathe for metalworking.Lathe conversions change a standard lathe into a better machine for metalworking. By upgrading parts, you can improve speed and precision. This makes your projects easier and more enjoyable. The main benefits include:

- Increased efficiency.

- Better accuracy in cuts.

- More options for different tasks.

Many metalworkers choose conversions to unlock their lathe’s full potential. With enhancements, they can achieve results that match professional standards!

What is a lathe conversion used for?

A lathe conversion is used to modify a standard lathe for better performance. This helps metalworkers cut materials more accurately.

Essential Tools and Materials for Lathe Conversion

List of necessary tools for a successful conversion. Recommended materials for building or upgrading gear trains.To successfully convert a lathe, you need the right tools and materials. Here’s a quick list of essential items:

- Wrenches

- Drills

- Screwdrivers

- Measuring tools

- Work gloves

For upgrading gear trains, consider these recommended materials:

- Metal rods

- Gears

- Bearings

- Frames for support

These tools and materials will help you create a stronger, more efficient machine. Start gathering them for your project!

What tools do you need for lathe conversion?

The main tools you need are wrenches, drills, and screwdrivers. Measuring tools and safety gloves are also important.

What materials should you use for gear trains?

For building gear trains, it’s best to use metal rods, gears, and bearings. These materials ensure strength and durability.

Step-by-Step Process for Lathe Conversion

Detailed instructions for dismantling the existing gear train. Guide to installing new components and adjustments.Begin by carefully taking apart the old gear train. Use a screwdriver to unscrew any bolts. Keep all parts in a container for easy access. Next, install the new components. Make sure each piece fits correctly. Tightly secure everything with bolts. Finally, check all adjustments. Test the lathe to ensure it runs smoothly.

What should I know before starting a lathe conversion?

Understand the size and type of parts needed for your specific lathe model. This makes the process easier and more efficient.

Quick Steps to Remember:

- Dismantle the old gear train carefully.

- Store parts safely.

- Install new parts correctly.

- Adjust for smooth operation.

Common Challenges in Lathe Conversion

Identification of potential problems and hurdles during conversion. Solutions and tips to overcome these challenges effectively.Converting a lathe can come with its share of hiccups. First, you might face issues with the gear train. If the gears don’t fit well, it can lead to a noisy machine. To fix this, double-check compatibility before starting. Another common problem is misalignment during installation. This can cause parts to wear unevenly. A simple tip? Use a level to ensure everything lines up. Remember, patience is key—like waiting for a cake to bake! Below is a quick summary of challenges and solutions:

| Challenge | Solution |

|---|---|

| Poor gear fit | Check compatibility |

| Misalignment | Use a level |

| Excess vibration | Secure all bolts |

With these tips, you’ll sail through the conversion like a pro! Remember, every expert was once a beginner, probably jiggling a few screws too!

Practical Applications of Converted Lathes

Examples of projects and tasks suited for converted metal lathes. Benefits of gear train enhancements on machining capabilities.Converted lathes are useful machines for various projects. People can create parts for tools, toys, or even small furniture. Enhanced gear trains boost the machine’s ability to work on different materials like wood and metal. They help make precise cuts and get better finishes. Here are some tasks suited for converted lathes:

- Making custom fittings

- Creating artistic sculptures

- Crafting precision model parts

Upgrading to a better gear train can turn a basic lathe into a powerful tool. This means you can do more complex tasks faster and easier.

What can you make with a converted lathe?

You can make parts for machines, crafts, and prototypes with a converted lathe. These machines are great for creating unique projects and enhancing your skills.

Maintenance Tips for Converted Lathes

Best practices for maintaining gear trains and overall lathe performance. Signs of wear and when to perform repairs or upgrades.Keeping your converted lathe in good shape is key to success. Follow these tips for a smooth ride:

- Check your gear train regularly for any loose parts.

- Listen for strange sounds while the lathe runs; they may mean trouble.

- Clean the lathe often to prevent buildup and increase performance.

- Replace worn-out gears before they break, avoiding downtime.

Remember, regular maintenance can save time and money!

How do I know if my lathe needs repairs?

Look for signs like strange noises, uneven cuts, or a decrease in speed. These can indicate that repairs or upgrades are needed. Checking your machine regularly helps catch problems early.

Comparing DIY versus Professional Lathe Conversion Services

Pros and cons of undertaking a DIY conversion. When to consider hiring a professional for the job.When choosing between DIY and professional lathe conversion services, weigh the pros and cons. DIY offers cost savings but may require time and learning. A skilled person might enjoy the challenge. However, mistakes can lead to wasted materials and extra costs.

Hiring a professional is great if you lack experience or want quality work. They ensure safety and efficiency. Think about your skill level and time. Always choose what suits your needs best.

What are the advantages of DIY over professional services?

The main benefits of DIY include cost savings and personal satisfaction. You learn new skills and have full control over the project.

When should you hire a professional for lathe conversion?

If you lack experience, hiring a professional is wise. They provide expert advice and save you from costly mistakes. Consider their help for complex projects.

Resources and Community Support for Lathe Enthusiasts

Online platforms and forums for sharing experiences and advice. Recommended videos and manuals for further learning.If you’re diving into the world of lathe conversion, finding fellow enthusiasts can make your journey much easier. Online platforms and forums are bursting with friendly folks ready to share their experiences and tips. It’s like finding a treasure map, but instead of gold, you find helpful advice! Videos and manuals are also great resources. They can turn complicated tasks into easy peasy DIY adventures. Check out the table below for some top picks!

| Resource Type | Name |

|---|---|

| Forum | LatheUser Forum |

| Video | Make It Yourself – Lathe Basics |

| Manual | Ultimate Lathe Guide |

Diving into these resources can transform you from a newbie to a lathe legend before you know it! Remember, every expert was once a beginner. So, grab your tools and join the fun!

Conclusion

In summary, a lathe conversion lets you turn a regular lathe into a metal lathe. Understanding the gear train is key to making it work well. You can improve your skills and precision by learning more about lathe conversions. We encourage you to explore guides and resources on this topic for better results in your projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Conversion For A Metal Lathe Gear Train:Sure! When you want to change a metal lathe, you might ask about its gear train. A gear train helps the lathe turn and shape metal. You may wonder what parts you need for the conversion. You should also think about how to adjust the speed. Lastly, you can explore common problems and how to fix them.

Sure! Please provide the question you’d like me to answer.

What Are The Essential Components Needed For Converting A Standard Lathe Into A Gear-Driven Metal Lathe?To change a regular lathe into a gear-driven lathe, you need a few key parts. First, get gears that will connect to the spindle. Next, you need a gear train, which helps turn the lathe at different speeds. A strong motor is also necessary to power the gears. Finally, you may need some belts and a way to adjust the tension.

How Does The Gear Ratio In The Gear Train Affect The Speed And Torque Of A Metal Lathe During Operation?The gear ratio in a gear train helps control how fast and strong the metal lathe can work. If the gear ratio is high, the lathe spins faster but has less strength, or torque. If the gear ratio is low, it spins slower but has more strength. This means we can choose the right gear ratio for the job we’re doing. So, you can make the lathe work quickly or powerfully by adjusting the gears!

What Are The Advantages And Disadvantages Of Using A Gear Train Versus A Belt Drive System In A Converted Metal Lathe?Using a gear train has some good and bad points. Gears are strong and can give you more power. They usually last longer than belts. But they can be noisy and harder to fix. Belt drives are quieter and easier to change. However, they might wear out faster and can slip if not tight enough. So, think about what you want before you choose!

How Can One Calculate The Optimal Gear Sizes And Arrangements For Specific Metalworking Tasks On A Lathe?To find the best gear sizes for a lathe, you first need to know what you want to make. Then, you can look at the size of the metal piece and how fast it needs to spin. Use a gear calculator to help you choose the right sizes. Finally, arrange the gears so they work together smoothly. This way, you can make your metal project just right!

What Modifications Might Be Required To Accommodate Different Materials Being Machined When Converting A Lathe’S Gear Train System?To change the lathe’s gear train system for different materials, you might need to adjust the gear sizes. Softer materials may need faster speeds, while harder ones might need slower speeds. You could also change the type of blades to suit the material better. Lastly, check the overall strength of the lathe to make sure it can handle the new material safely.