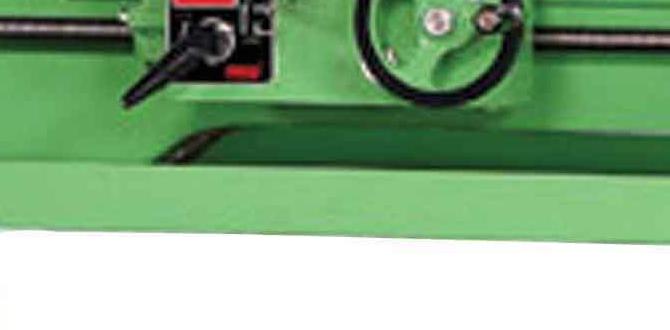

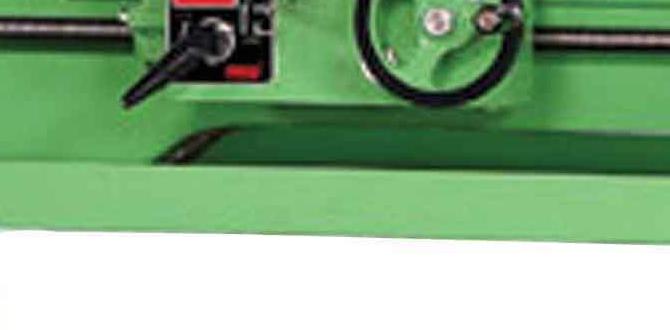

Have you ever wondered how metal parts get their precise shapes? A lathe is one of the best tools for this job. But did you know you can convert a regular machine into a fantastic metal lathe?

Many people love working with tools and creating new things. A lathe conversion can turn your old machine into a powerful metal lathe capable of threading. There’s a special part called a threading dial that makes these adjustments super easy.

Imagine being able to cut threads just right every time. It makes working with metal much more fun! In this article, we will explore how a lathe conversion can be a game-changer for anyone who enjoys tinkering with machines.

Are you ready to learn more about metal lathe threading dials and how they can boost your projects? Let’s dive in and see what this exciting journey has to offer!

Lathe Conversion: Upgrading Your Metal Lathe Threading Dial

Lathe Conversion with Metal Lathe Threading Dial

Converting a lathe into a more effective tool can be exciting. The metal lathe threading dial is essential for precision. It helps you create accurate threads in your projects. Did you know that using this tool can turn a simple metal piece into a work of art? Some people find it tricky, but with practice, your skills will shine. Want to impress friends with your new metalworking abilities? The threading dial could be your secret weapon!Understanding Lathe Conversion

Definition and purpose of lathe conversion. Benefits of converting a standard lathe.Lathe conversion is the process of upgrading a standard lathe to improve its functions. This can help craftsmen create better products. Converting a lathe allows users to tackle more complex projects with ease. It also increases machine flexibility.

- Improved Precision: Converted lathes often provide finer control.

- Expanded Capabilities: They can perform threading, which is useful for making screws.

- Cost-Effective: Upgrading rather than purchasing new machines saves money.

In summary, a lathe conversion enhances performance and helps makers use their tools more effectively.

What are the benefits of lathe conversion?

The benefits of converting a lathe include better precision, greater capability to complete various tasks, and saving money on new equipment.

What is a Threading Dial?

Explanation of a threading dial’s function in lathe operations. Benefits of having a threading dial on your lathe.A threading dial is a helpful tool on a lathe. It helps you cut threads accurately. When you use a lathe for metal work, the threading dial makes sure your cuts line up perfectly. This is important to make tight and precise screws or parts.

Here are some benefits:

- Improves thread accuracy

- Saves time

- Easy to read

- Helps avoid mistakes

Having a threading dial can make a big difference in your projects. It allows you to create better and more professional results. Imagine making a perfect screw that fits exactly where you need it!

How does a threading dial work?

A threading dial shows where to start your next cut. It counts the revolutions of the lathe. This helps keep your threads evenly spaced. It is important for quality work.

Steps for Converting a Metal Lathe

Detailed process of converting a standard lathe. Essential tools and materials required for conversion.Converting a lathe can be fun and rewarding! Start by gathering essential tools. You will need:

- A wrench set

- Screwdrivers

- Precision measuring tools

- New threading dials

- Safety glasses

Next, follow the steps. First, unplug the lathe for safety. Remove the old components, like the carriage and existing dials. Install the new threading dial carefully. Finally, check all parts to ensure they fit well. Test the lathe to make sure everything runs smoothly.

How do you convert a metal lathe?

To convert a metal lathe, gather your tools, remove the current parts, and fit in new ones. Don’t skip testing after the change!

Installing a Threading Dial

Stepbystep installation guide for threading dial. Common challenges and solutions during installation.Installing a threading dial can be simple—like pie, but without the calories! Start by gathering your tools: a wrench, screwdrivers, and a little patience. First, locate the mounting area on your lathe. Attach the dial using the screws provided. Remember, don’t over-tighten; you’re not wrestling an alligator! If the dial doesn’t line up, check your placement. Some common hiccups include misaligned screws or confusing instructions. But fear not! A little adjustment often works wonders.

| Challenge | Solution |

|---|---|

| Misalignment | Recheck the mounting position |

| Loose screws | Tighten gently—don’t force! |

When all else fails, remember: even the best mechanics started at square one. Keep calm and thread on!

Adjustments and Calibration

Importance of calibrating the threading dial after installation. Tips for accurate adjustments to improve threading precision.Calibrating the threading dial is crucial after installation. It snags the right measurements and helps avoid threading blunders! Accurate adjustments can make your threads smoother than a buttered slide. Start by referencing the manual for the best setup. Here’s a handy table of tips for perfecting that threading dial:

| Tip | Description |

|---|---|

| Check Alignment | Make sure everything is straight. Squiggly lines are for worms, not threads! |

| Measure Twice | A quick double-check can save you from redoing your work. Remember, practice makes perfect! |

| Fine-Tune Settings | Adjust until it’s just right. Like Goldilocks, find your perfect fit! |

Taking time for adjustments pays off. It boosts threading precision, helping you create quality work. So, don’t rush! Happy threading!

Maintenance of Converted Lathes

Routine maintenance checks for longevity of conversions. Best practices to ensure optimal performance of the threading dial.Keeping your converted lathe in top shape is like feeding a pet: regular care keeps it happy and working well. Routine checks are important for lasting conversions. Make sure to look for worn parts and loose screws, just like checking for monster dust bunnies under the bed!

For the threading dial, smooth operation is key. Clean it often and keep the mechanisms lubricated. Think of it as giving your lathe a spa day—refreshing and necessary!

| Maintenance Tip | Purpose |

|---|---|

| Check for wear | Prevents bigger problems |

| Clean threading dial | Ensures smooth threading |

| Lubricate parts | Minimizes friction |

Case Studies: Successful Lathe Conversions

Examples of transformations and their impact on machining efficiency. Lessons learned and best practices from experienced lathe users.Many lathe users have improved their machines through fascinating conversions. For example, a team upgraded a standard lathe, boosting its speed and accuracy. This change helped them complete projects faster and with better quality. Experienced users suggest these tips:

- Understand your machine: Know its parts well.

- Plan conversions carefully: Think ahead to avoid mistakes.

- Test often: Run trials to ensure everything works smoothly.

These lessons show how smart changes can make a big difference!

How can lathe conversions improve efficiency?

Converting a lathe can greatly speed up production and enhance precision. Users see major benefits from updating their machines, which leads to better work outcomes and less waste.

Frequently Asked Questions

Common queries regarding lathe conversions and threading dials. Expert answers to assist novice and experienced machinists.Many people have questions about lathe conversions and threading dials. Here are some common queries:

What is a lathe conversion?

A lathe conversion changes a machine for better performance. It can help with threading and other tasks, making work easier and more precise.

How does a threading dial work?

- The threading dial helps align threads.

- It shows the right point to start a new thread.

Can beginners use it?

Yes, beginners can use it! With some practice, they can learn to use a threading dial easily and gain more skills.

If you’re looking for help, remember, expert advice is available to assist both novice and experienced machinists!

Conclusion

In conclusion, a lathe conversion for metal lathe threading dials can improve your machining skills. You gain better accuracy and control over your projects. Understanding threading dials helps you make precise cuts. Explore tutorials online to learn more. With practice, you can master these techniques and enhance your metalworking. Keep experimenting, and have fun creating!FAQs

What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Improve Threading Accuracy?A threading dial on a metal lathe helps you make accurate threads on metal pieces. It shows you exactly when to move the tool for the next pass. This way, your threads match perfectly and look nice. Without it, your threads might be uneven or too tight. Using a threading dial makes your work better and easier!

How Can I Convert A Standard Lathe To Enable Threading With A Dial, And What Components Are Required For This Conversion?To convert a standard lathe for threading, you need a few important parts. First, get a threading dial. This helps you know when to move the tool for threading. You also need a change gear set to help control the speed of the lathe. Finally, make sure you have the right cutting tool for threading. With these parts, you can easily do threading on your lathe.

What Are The Different Types Of Threading Dials Available For Metal Lathes, And How Do Their Features Differ?There are two main types of threading dials for metal lathes: drop feed dials and split dials. A drop feed dial lets you adjust the thread easily and has markers that help you know where to stop. A split dial has two parts and can make it easier to follow the lines while you cut. Both dials help you make nice threads but work a bit differently. Choosing one depends on what you like and how you plan to use it.

What Techniques Should Be Employed When Using A Threading Dial To Ensure Precise And Consistent Threads?To use a threading dial well, keep your machine steady. Start the thread correctly and make sure it runs smoothly. Watch the numbers on the dial closely as you turn. Always follow the same slow speed to get even threads. Finally, double-check your work to make sure the threads are straight and neat.

How Do You Troubleshoot Common Issues That May Arise While Using A Threading Dial On A Metal Lathe?To troubleshoot problems with a threading dial on a metal lathe, first, check if it lines up with the tool correctly. If it doesn’t, you might need to adjust the dial. Next, make sure the machine is set to the right speed for threading. If the thread doesn’t look right, try adjusting the feed rate. Lastly, always clean the dial to remove any dirt or oil that can cause issues.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Improve Threading Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial on a metal lathe helps you make accurate threads on metal pieces. It shows you exactly when to move the tool for the next pass. This way, your threads match perfectly and look nice. Without it, your threads might be uneven or too tight. Using a threading dial makes your work better and easier!”}},{“@type”: “Question”,”name”: “How Can I Convert A Standard Lathe To Enable Threading With A Dial, And What Components Are Required For This Conversion? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To convert a standard lathe for threading, you need a few important parts. First, get a threading dial. This helps you know when to move the tool for threading. You also need a change gear set to help control the speed of the lathe. Finally, make sure you have the right cutting tool for threading. With these parts, you can easily do threading on your lathe.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Threading Dials Available For Metal Lathes, And How Do Their Features Differ? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are two main types of threading dials for metal lathes: drop feed dials and split dials. A drop feed dial lets you adjust the thread easily and has markers that help you know where to stop. A split dial has two parts and can make it easier to follow the lines while you cut. Both dials help you make nice threads but work a bit differently. Choosing one depends on what you like and how you plan to use it.”}},{“@type”: “Question”,”name”: “What Techniques Should Be Employed When Using A Threading Dial To Ensure Precise And Consistent Threads? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use a threading dial well, keep your machine steady. Start the thread correctly and make sure it runs smoothly. Watch the numbers on the dial closely as you turn. Always follow the same slow speed to get even threads. Finally, double-check your work to make sure the threads are straight and neat.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Common Issues That May Arise While Using A Threading Dial On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot problems with a threading dial on a metal lathe, first, check if it lines up with the tool correctly. If it doesn’t, you might need to adjust the dial. Next, make sure the machine is set to the right speed for threading. If the thread doesn’t look right, try adjusting the feed rate. Lastly, always clean the dial to remove any dirt or oil that can cause issues.”}}]}