Have you ever wondered how precise your lathe can be? The secret often lies in the lathe cross slide dial calibration. This small part may seem unimportant, but it plays a big role in making sure your projects turn out just right.

Imagine working on a beautiful piece of wood. You start cutting, but it doesn’t look like you hoped. Frustrating, right? If your cross slide dial isn’t calibrated, even a tiny mistake can lead to big problems. That’s why calibration is so crucial.

Many people don’t realize that checking this dial can greatly improve their work quality. It can mean the difference between a great piece and a mediocre one. So, how can you ensure your lathe is working as it should? Let’s find out!

Lathe Cross Slide Dial Calibration: Essential Tips And Techniques

Lathe Cross Slide Dial Calibration

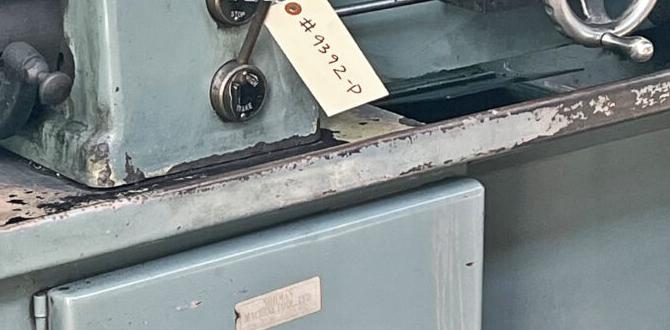

Calibrating the lathe cross slide dial ensures accurate measurements. This process helps prevent mistakes while working on projects. Have you ever wondered why precision matters? A small error can lead to a big issue in your final product. To start, clean the cross slide thoroughly. Then, you’ll adjust the dial to match the actual movement. How cool is it that a simple twist can make your work much more precise? Proper calibration saves time and materials while boosting your confidence in your craft.Understanding Lathe Cross Slide Dial

Definition and purpose of the cross slide dial. Importance of accurate calibration for precision machining.The cross slide dial is a handy tool on a lathe machine. It shows how far the cutting tool moves horizontally. Its main purpose is to help workers cut accurately. Imagine trying to slice a pizza without knowing where the cheese is! That’s why calibrating the dial is key for precision machining. If the dial is off, you could end up with a pizza that’s more crust than cheese. Calibration ensures accurate measurements, making every cut perfect.

| Key Points | Why It Matters |

|---|---|

| Cross Slide Dial | Helps in measuring horizontal movements. |

| Calibration | Ensures precise cuts, saves materials. |

Tools Required for Calibration

List of essential tools needed for calibration. Optional tools for enhanced precision.Before diving into calibration fun, gather your trusty tools. You’ll need a few essentials for a smooth ride. Think of a caliper for precise measurements and a wrench to make adjustments. If you want to be a calibration superhero, consider using a dial indicator for extra accuracy. Bring in a platform scale to double-check those heavy numbers. Here’s a quick table to help you:

| Essential Tools | Optional Tools |

|---|---|

| Caliper | Dial Indicator |

| Wrench | Platform Scale |

| Level | Tape Measure |

With these tools, you’re set to tackle any calibration challenge. Just remember, even the best tools can’t replace a bit of patience (and maybe a snack for energy)!

Step-by-Step Calibration Process

Detailed procedure for calibrating the cross slide dial. Common mistakes to avoid during calibration.To calibrate the cross slide dial, follow these steps:

- First, measure the travel distance of the slide.

- Next, set the dial to zero.

- Move the slide a known distance.

- Check if the dial matches the distance moved.

- If not, adjust it until it is correct.

Common mistakes include:

- Forgetting to zero the dial before measuring.

- Over-tightening adjustments.

- Not checking the tool’s level.

Following these steps carefully helps ensure accurate readings and better work results.

What is the purpose of calibrating the cross slide dial?

The main goal of calibration is to improve precision. Accurate measurements lead to better cuts and overall quality in projects.

Checking Calibration Accuracy

Methods to verify the accuracy of calibration. Importance of repeated measurements.It’s important to check the accuracy of your lathe cross slide dial calibration. There are simple methods to do this. You can compare the dial reading with a known measurement. Repeated measurements help ensure your findings are correct. It’s like testing your math answers; checking them gives you confidence!

- Take multiple readings

- Use different tools for accuracy

- Record your findings

These steps show you are precise. Remember, even small errors can lead to big mistakes later. Always double-check!

Why is repeated measurement important?

Repeated measurements help find real results. They reduce errors and give you confidence in your calibration.

Troubleshooting Calibration Issues

Common issues faced during calibration and their solutions. Tips for maintaining longterm accuracy.Calibration issues can be tricky, but they often have simple fixes. One common problem is the dial not reading correctly. This could be due to wear and tear, or something even more fun, like a sneaky piece of dust! Always clean your equipment to avoid misreadings. For long-term accuracy, check your calibration regularly, maybe even treat it like a pet! For reference, here’s a quick troubleshooting table:

| Issue | Solution | Tip |

|---|---|---|

| Incorrect Dial Reading | Clean and adjust | Check monthly |

| Sticking Slide | Lubricate | Use light oil |

| Wear and Tear | Replace parts | Inspect regularly |

With these tips, your lathe should be as happy as a clam! Remember, regular maintenance is key to avoiding headaches. Don’t let calibration issues turn your day into a “lathe-ical” comedy!

Impact of Improper Calibration

Effects on machining quality and production efficiency. Case studies highlighting consequences of inaccurate calibration.Improper calibration can make machining feel like a game of luck. Imagine needing precision, but getting wobbly results instead! This hurts both quality and speed. Poorly calibrated cross slides can lead to mistakes, wasting time and materials. In fact, studies show that even a tiny miscalibration can reduce efficiency by up to 30%. That’s like trying to bake a cake without measuring! Here’s a glimpse of the numbers:

| Calibration Error | Efficiency Loss |

|---|---|

| 1 mm | 15% |

| 2 mm | 25% |

| 3 mm | 30% |

These errors can lead to costly reworks. Nobody wants to be the person who made 100 faulty bolts! Proper calibration helps keep projects smooth and on budget.

Best Practices for Regular Maintenance

Routine checks for ensuring ongoing precision. Recommended schedule for recalibration.Keeping your lathe in top shape is like giving it a spa day! Regular checks help ensure everything runs smoothly. Check the dial for any signs of wear and tear. If you see something funky, it’s time to recalibrate. Experts suggest doing this every few months. Imagine your dial is like a dog; if it starts barking out of tune, it’s time for a check-up! Here’s a handy schedule:

| Check Type | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Calibration Check | Every 3 months |

| Full Maintenance | Annually |

Staying on top of these steps can save you from bigger problems down the road. Remember, “An ounce of prevention is worth a pound of fixin’!” – wise words for your lathe! Keep it calibrated, and it will keep you happy!

Conclusion

In conclusion, lathe cross slide dial calibration is essential for accuracy in machining. You can improve your work by ensuring your lathe’s dials are precise. Regular checks can prevent mistakes and save time. If you want to learn more, consider reading guides or watching videos on calibration techniques. This hands-on knowledge will help you become a better machinist!FAQs

Sure! Here Are Five Questions Related To Lathe Cross Slide Dial Calibration:Sure! Here are five questions about calibrating the lathe cross slide dial: 1. Why do we need to calibrate the cross slide dial? We calibrate it so the measurements are correct when we work. 2. How do we check if the dial is accurate? You can move the slide a small distance and see if the dial shows the same measurement. 3. What tools do we need for calibration? You need a ruler or a measuring tape to help you measure. 4. How often should we calibrate the cross slide dial? We should check it regularly, especially before starting a big project. 5. What happens if the dial isn’t calibrated? If it’s not right, you might cut the material too much or too little.

Sure! Just give me the question you’d like me to answer.

What Are The Steps To Accurately Calibrate The Cross Slide Dial On A Lathe?To calibrate the cross slide dial on a lathe, follow these steps. First, make sure the lathe is off and safe. Then, move the cross slide to zero using the handwheel. Next, check if the dial reads zero too. If it doesn’t, carefully loosen the dial and turn it to match the zero position. Tighten it again. Repeat this until the dial always shows the right position. Now you’re ready to start!

How Can Inaccuracies In The Cross Slide Dial Affect Machining Precision And Finished Part Quality?If the cross slide dial is not accurate, it shows wrong measurements. This means you might cut the metal or wood in the wrong place. When we make mistakes like that, the finished part doesn’t fit well. It can be loose or too tight, which can make it not work right. So, we need to be careful and make sure the dial is correct for good results.

What Tools And Equipment Are Necessary For Performing A Cross Slide Dial Calibration On A Lathe?To calibrate the cross slide dial on a lathe, you need a few tools. First, use a dial indicator to measure small distances accurately. Next, you’ll need a wrench to adjust the parts. A ruler can help you check the slide’s movement. Finally, have some clean cloths nearby to wipe off any dirt or grease.

How Do You Determine The Correct Zero Point For The Cross Slide Dial During Calibration?To find the correct zero point on the cross slide dial, you first set the tool to touch the workpiece. Next, you carefully turn the dial until it reads zero. This means the tool is perfectly lined up. If it doesn’t read zero, adjust the dial until it does. Now you’re ready to start your work!

What Are Common Signs That Indicate The Cross Slide Dial Of A Lathe Needs Recalibration?If the cross slide dial on a lathe shows wrong measurements, it might need recalibration. You might notice that the tool cuts too deep or too shallow. When you move the dial, if the tool doesn’t move as expected, that’s another sign. Also, if the measurements seem different each time you check, it’s time to fix it. Always double-check before starting your work!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Cross Slide Dial Calibration:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about calibrating the lathe cross slide dial: 1. Why do we need to calibrate the cross slide dial? We calibrate it so the measurements are correct when we work. 2. How do we check if the dial is accurate? You can move the slide a small distance and see if the dial shows the same measurement. 3. What tools do we need for calibration? You need a ruler or a measuring tape to help you measure. 4. How often should we calibrate the cross slide dial? We should check it regularly, especially before starting a big project. 5. What happens if the dial isn’t calibrated? If it’s not right, you might cut the material too much or too little.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Steps To Accurately Calibrate The Cross Slide Dial On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the cross slide dial on a lathe, follow these steps. First, make sure the lathe is off and safe. Then, move the cross slide to zero using the handwheel. Next, check if the dial reads zero too. If it doesn’t, carefully loosen the dial and turn it to match the zero position. Tighten it again. Repeat this until the dial always shows the right position. Now you’re ready to start!”}},{“@type”: “Question”,”name”: “How Can Inaccuracies In The Cross Slide Dial Affect Machining Precision And Finished Part Quality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the cross slide dial is not accurate, it shows wrong measurements. This means you might cut the metal or wood in the wrong place. When we make mistakes like that, the finished part doesn’t fit well. It can be loose or too tight, which can make it not work right. So, we need to be careful and make sure the dial is correct for good results.”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Necessary For Performing A Cross Slide Dial Calibration On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the cross slide dial on a lathe, you need a few tools. First, use a dial indicator to measure small distances accurately. Next, you’ll need a wrench to adjust the parts. A ruler can help you check the slide’s movement. Finally, have some clean cloths nearby to wipe off any dirt or grease.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Zero Point For The Cross Slide Dial During Calibration?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the correct zero point on the cross slide dial, you first set the tool to touch the workpiece. Next, you carefully turn the dial until it reads zero. This means the tool is perfectly lined up. If it doesn’t read zero, adjust the dial until it does. Now you’re ready to start your work!”}},{“@type”: “Question”,”name”: “What Are Common Signs That Indicate The Cross Slide Dial Of A Lathe Needs Recalibration?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the cross slide dial on a lathe shows wrong measurements, it might need recalibration. You might notice that the tool cuts too deep or too shallow. When you move the dial, if the tool doesn’t move as expected, that’s another sign. Also, if the measurements seem different each time you check, it’s time to fix it. Always double-check before starting your work!”}}]}