Have you ever wondered how precise cuts are made in metalworking? Imagine a machine that spins metal and shapes it perfectly. This machine is called a lathe. One key part of the lathe is the cross slide handwheel. But did you know it needs to be calibrated? Calibration ensures that the readings are exact.

Think about it. If your handwheel is off by even a tiny bit, your work can be affected. You could end up with pieces that don’t fit together! That’s where proper lathe cross slide handwheel calibration comes in. It makes sure everything works smoothly.

In this article, we will explore how to calibrate the handwheel. You will learn easy steps to follow. By the end, you will feel more confident using your lathe. So, let’s dive in and discover how to achieve perfect precision!

Lathe Cross Slide Handwheel Calibration: A Comprehensive Guide

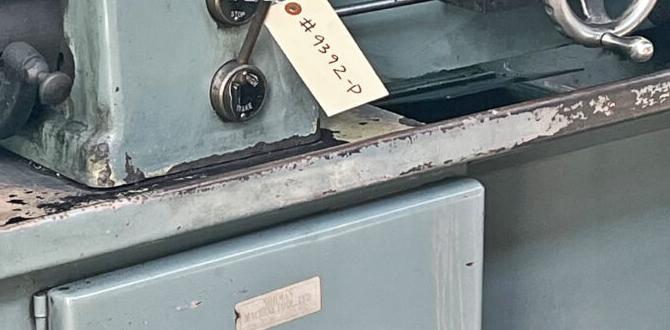

Lathe Cross Slide Handwheel Calibration

Calibrating the lathe cross slide handwheel is essential for precise machining. It ensures accuracy when making cuts. Did you know that even a tiny miscalibration can lead to big errors? To start, measure the travel of the handwheel and check for consistency. Adjust the handwheel to align with your scale. This simple step can enhance your project’s quality and reduce waste. Remember, precise measurements lead to professional results. Happy turning!Understanding Lathe Cross Slide Mechanics

Explanation of cross slide function in lathe operation. Importance of accuracy in calibration for precision work.The cross slide plays a key role in lathe operations. It helps move the cutting tool back and forth. This movement is crucial for shaping materials accurately. Accuracy in calibration is vital for precise work. A small mistake can lead to big problems in the final product. So, a well-calibrated cross slide ensures smooth and exact cuts, keeping projects on track.

What is cross slide function in lathe operation?

The cross slide moves the cutting tool laterally, allowing it to make precise cuts on the material being shaped.

Why is calibration important?

- It ensures accuracy: Even tiny errors can affect the finished piece.

- Improves quality: Better calibration leads to smoother finishes.

- Reduces waste: Accurate settings cut down on mistakes, saving time and materials.

Tools and Materials Needed for Calibration

List of essential tools required for effective calibration. Recommended materials for testing and adjustments.To properly calibrate a lathe cross slide handwheel, gather these essential tools and materials:

- Caliper or ruler for measuring

- Wrench for tightening bolts

- Level for checking flatness

- Feeler gauge for precise gaps

- Calibration test bar for accuracy

Having these items will help make your adjustments easier and more accurate. Use high-quality materials to test and fine-tune your settings. An excellent calibration ensures better performance and reduces errors while working on projects.

What materials do you need for proper calibration?

Use measurement tools like calipers and levels for accuracy. A calibration test bar and feeler gauges will help ensure everything is spot on.

Step-by-Step Calibration Process

Detailed steps for calibrating the cross slide handwheel. Tips for ensuring accuracy at each step.Calibrating the cross slide handwheel is important for precision. Follow these steps to ensure it works well:

- Start by loosening the handwheel.

- Align the slide to zero using a dial indicator.

- Carefully tighten the handwheel without disturbing the alignment.

- Test the handwheel by moving it back and forth. Check its accuracy.

For the best results, make sure to do this in a well-lit area. Double-check each step to avoid mistakes. Remember, a properly calibrated handwheel means better work!

What is the purpose of calibration?

The purpose of calibration is to ensure accuracy in measurements. It makes sure your tools give correct readings. This helps create better products.

Common Calibration Issues and Solutions

Identification of frequent problems encountered during calibration. Effective troubleshooting methods to resolve these issues.Calibration issues can be tricky. Often, people face these common problems:

- Incorrect measurements

- Loose connections

- Old or worn parts

To solve these problems, try these troubleshooting tips:

- Check all connections carefully.

- Replace worn-out parts immediately.

- Re-measure to ensure accuracy.

Fixing these issues helps keep your lathe cross slide handwheel working smoothly.

What are common calibration mistakes?

Common calibration mistakes include skipping steps, using old tools, and ignoring the manual. These can lead to inaccurate results and wasted time.

How can I avoid calibration problems?

To avoid problems, always follow the instructions, use proper tools, and check settings regularly. This will ensure your machine runs well and lasts longer.

Maintaining Your Lathe Post-Calibration

Best practices for maintaining calibration over time. Routine checks and adjustments for longterm accuracy.To keep your lathe working well, regular checks are key. This means looking at the calibration often. Small changes can happen over time. Here are some best practices:

- Check the handwheel’s movement regularly.

- Look for any signs of wear on parts.

- Tighten loose screws or bolts immediately.

- Use a caliper to verify measurements.

- Keep the machine clean to prevent dirt buildup.

Doing these steps often can help you catch problems early. A well-maintained lathe will work better and last longer.

How can I ensure my lathe stays calibrated?

You can ensure your lathe stays calibrated by performing routine checks on its settings and using proper maintenance techniques. Regularly inspect parts and clean the machine. This keeps your readings accurate.

The Benefits of Proper Calibration

Impact of accurate calibration on machining quality. Financial and time savings from reduced errors in the long run.Good calibration makes a big difference in machining. With accurate calibration, machines work better and create high-quality products. This can lead to fewer mistakes and less waste. In the long run, this also saves money and time.

- Better accuracy means less reworking.

- Fewer errors cut costs on materials.

- Higher quality leads to happy customers.

In fact, studies show that proper calibration can reduce errors by over 25%. This not only improves product quality but also boosts profits. Isn’t that a win-win?

Why is calibration important?

Calibration is critical because it ensures machines operate precisely, leading to consistent and reliable results.

Benefits of proper calibration:

- Improves production efficiency.

- Reduces machine wear and tear.

Expert Tips and Tricks

Insights from experienced machinists on efficient calibration. Advanced techniques for enhanced accuracy and performance.Experienced machinists share great tips for calibrating your lathe cross slide handwheel. Here are some effective methods to achieve precise results:

- Always start by checking the level of your lathe. A level surface is key for accuracy.

- Use a dial indicator to measure movement. This tool will give you clear readings.

- Adjust the handwheel slowly. Small movements lead to better results.

- Don’t forget to document your settings. This will help you repeat successful calibrations.

- Regular adjustments keep your machine running smoothly and accurately.

Incorporate these techniques, and watch your performance improve!

How do I know if my calibration is accurate?

To check accuracy, perform a test cut on a piece of scrap material. Measure the cut with a caliper. If dimensions match your settings, you’re calibrated well. If not, adjust and try again!

Conclusion

In conclusion, calibrating the lathe cross slide handwheel is vital for accuracy. It helps us create precise cuts in our projects. You can ensure your measurements are correct by checking the handwheel regularly. We encourage you to practice this calibration and explore more resources on lathe operations for better results. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cross Slide Handwheel Calibration:Sure! When we talk about lathe cross slide handwheel calibration, it means checking if the handwheel is correct. First, you need to measure the movement of the slide. Then, you compare it to what the handwheel shows. If the numbers don’t match, we adjust the handwheel. This makes sure everything works right when we use the lathe.

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!

What Are The Common Methods Used To Calibrate The Cross Slide Handwheel On A Lathe?To calibrate the cross slide handwheel on a lathe, you can use a few simple methods. First, you can measure the distance the tool moves using a ruler or caliper. Next, you can adjust the handwheel to match the actual movement. Another method is to use a dial indicator, which tells you how far the tool moves. Always check your settings to make sure they are accurate before starting your work!

How Often Should The Cross Slide Handwheel Calibration Be Checked Or Adjusted For Optimal Performance?You should check the cross slide handwheel calibration regularly, about every few months. If you notice any problems while using the machine, check it sooner. Keeping it calibrated helps everything work better. Regular checks make sure your work is accurate and smooth.

What Tools Are Necessary To Accurately Calibrate The Cross Slide Handwheel Of A Lathe?To calibrate the cross slide handwheel of a lathe, you need a few simple tools. First, you will want a screwdriver to adjust screws. A ruler helps you measure distances accurately. A dial indicator checks how far the cross slide moves. Finally, a wrench ensures everything is tight and in place. With these tools, you can make sure your lathe works correctly!

What Are The Signs That Indicate The Cross Slide Handwheel On A Lathe May Be Out Of Calibration?You might notice the patterns on your workpiece look strange or uneven. If the tool doesn’t move smoothly when you turn the handwheel, that’s a sign too. Also, if you move the handwheel, but the tool doesn’t move as expected, something’s off. Finally, if the numbers on the handwheel don’t match what you expect, it may need fixing.

How Does Incorrect Calibration Of The Cross Slide Handwheel Impact Machining Accuracy And Workpiece Quality?If the cross slide handwheel isn’t calibrated correctly, it can cause mistakes in cutting. This means the piece we are working on might not be the right shape or size. It can also make the surface look rough or uneven. When we measure and adjust correctly, we make sure our workpiece is better and fits well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cross Slide Handwheel Calibration:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When we talk about lathe cross slide handwheel calibration, it means checking if the handwheel is correct. First, you need to measure the movement of the slide. Then, you compare it to what the handwheel shows. If the numbers don’t match, we adjust the handwheel. This makes sure everything works right when we use the lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Common Methods Used To Calibrate The Cross Slide Handwheel On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the cross slide handwheel on a lathe, you can use a few simple methods. First, you can measure the distance the tool moves using a ruler or caliper. Next, you can adjust the handwheel to match the actual movement. Another method is to use a dial indicator, which tells you how far the tool moves. Always check your settings to make sure they are accurate before starting your work!”}},{“@type”: “Question”,”name”: “How Often Should The Cross Slide Handwheel Calibration Be Checked Or Adjusted For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the cross slide handwheel calibration regularly, about every few months. If you notice any problems while using the machine, check it sooner. Keeping it calibrated helps everything work better. Regular checks make sure your work is accurate and smooth.”}},{“@type”: “Question”,”name”: “What Tools Are Necessary To Accurately Calibrate The Cross Slide Handwheel Of A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the cross slide handwheel of a lathe, you need a few simple tools. First, you will want a screwdriver to adjust screws. A ruler helps you measure distances accurately. A dial indicator checks how far the cross slide moves. Finally, a wrench ensures everything is tight and in place. With these tools, you can make sure your lathe works correctly!”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate The Cross Slide Handwheel On A Lathe May Be Out Of Calibration?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice the patterns on your workpiece look strange or uneven. If the tool doesn’t move smoothly when you turn the handwheel, that’s a sign too. Also, if you move the handwheel, but the tool doesn’t move as expected, something’s off. Finally, if the numbers on the handwheel don’t match what you expect, it may need fixing.”}},{“@type”: “Question”,”name”: “How Does Incorrect Calibration Of The Cross Slide Handwheel Impact Machining Accuracy And Workpiece Quality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the cross slide handwheel isn’t calibrated correctly, it can cause mistakes in cutting. This means the piece we are working on might not be the right shape or size. It can also make the surface look rough or uneven. When we measure and adjust correctly, we make sure our workpiece is better and fits well.”}}]}