Have you ever watched a lathe in action? It’s fascinating to see how it shapes metal or wood. One important part of a lathe is the cross slide. This piece helps control the tool and cut precisely. But what happens when it doesn’t work correctly? A misaligned cross slide can lead to errors in your work.

Many makers wonder how to fix this problem. Did you know that adjusting the taper on the cross slide can make a big difference? It’s true! Finding the right adjustment can improve your accuracy. Imagine crafting a perfect piece, all because you took the time to adjust the cross slide taper.

In this article, we will explore the steps to adjust the lathe cross slide taper. You will learn tips and tricks that can help you become a better craftsman. Whether you are a beginner or have some experience, this guide will have something for you. Ready to dive in and enhance your lathe skills?

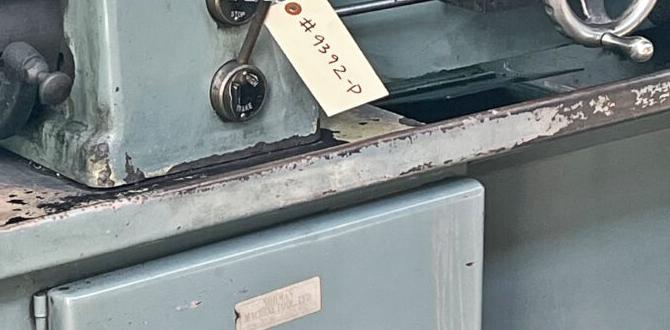

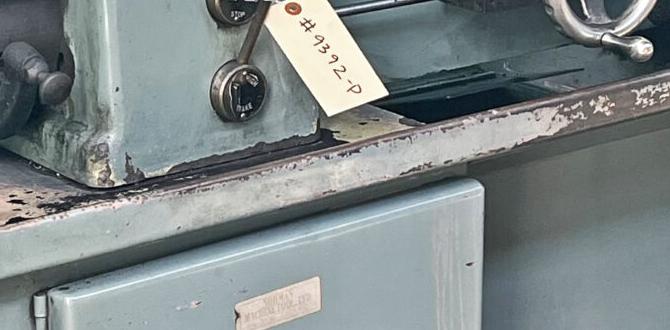

Lathe Cross Slide Taper Adjustment: A Complete Guide The Lathe Cross Slide Taper Adjustment Is An Essential Process For Precision Machining. Properly Adjusting The Taper Ensures That Your Workpieces Are Accurately Shaped, Leading To Better Finishes And Higher Quality Output. This Guide Will Delve Into The Importance Of This Adjustment, How To Perform It Effectively, And Tips For Maintaining Your Lathe To Ensure Consistent Performance. Understanding Taper Adjustment In Lathe Operations Taper Adjustment On A Lathe Is Critical For Ensuring That The Tool Moves At The Correct Angle Relative To The Workpiece. This Adjustment Allows You To Create Tapers, Which Are Essential In Various Machining Processes. The Cross Slide On A Lathe Provides Vertical Movement, While The Taper Adjustment Allows Fine-Tuning Of This Motion To Achieve The Desired Angle. Tools Required For Lathe Cross Slide Taper Adjustment Before You Begin The Adjustment, Gather The Necessary Tools. You’Ll Typically Need: – A Precision Level – A Dial Indicator – A Set Of Wrenches – Allen Keys – A Protractor Or Taper Gauge Having The Right Tools Will Make The Adjustment Process Smoother And More Accurate. Step-By-Step Guide To Adjusting Your Lathe Cross Slide Taper 1. **Preparation**: Start By Cleaning Your Lathe To Ensure There Is No Debris That Could Affect Adjustments. 2. **Check Level**: Use The Precision Level To Ensure Your Lathe Is Properly Leveled. 3. **Dial Indicator Setup**: Attach The Dial Indicator To Measure Any Deviation In Your Cross Slide. 4. **Adjust The Cross Slide**: Loosen The Necessary Screws Or Bolts That Hold The Cross Slide In Place. Carefully Make Adjustments, Usually By Rotating Screws That Set The Angle. 5. **Test And Measure**: After Making An Adjustment, Test It By Cutting A Small Workpiece And Measuring The Taper Using Your Protractor Or Taper Gauge. 6. **Fine-Tune As Necessary**: Repeat The Process Until You Achieve The Desired Results. Maintenance Tips For Lathe Precision Once You Have Completed The Taper Adjustment, It’S Important To Maintain Your Lathe For Ongoing Accuracy. Here Are Some Tips: – Regularly Clean The Machine And Remove Any Chips Or Dust. – Lubricate Moving Parts As Per The Manufacturer’S Recommendations. – Conduct Regular Checks On All Adjustments To Ensure Precision. – Keep Your Tools Organized And In Good Condition To Facilitate Adjustments And Repairs. By Following This Guide, You Can Master The Lathe Cross Slide Taper Adjustment, Improve Your Machining Precision, And Ultimately Enhance Your Work Quality.

Lathe Cross Slide Taper Adjustment

Lathe cross slide taper adjustment can seem tricky, but it’s important for accuracy. This adjustment ensures that the tool moves evenly, resulting in smooth cuts. Did you know that even a small miscalculation can lead to uneven pieces? To adjust, check the taper guide and loosen screws. This simple technique can improve your lathe work significantly. Understanding how to make these adjustments could turn a good project into a great one!Importance of Proper Taper Adjustment

Effects of incorrect taper adjustments on machining accuracy. Benefits of precise settings for enhanced workflow and output quality.Proper taper adjustment is key for smooth machining. If the taper is wrong, it can cause poor cuts and uneven surfaces. This leads to lost time and wasted materials. Correct adjustments help improve workflow and quality. A precise setup ensures parts fit well and work as they should. This makes the whole process faster and more efficient.

What are the effects of incorrect taper adjustments?

Incorrect taper adjustments can cause inaccuracies in cutting. It may lead to:

- Poor surface finish

- Increased tool wear

- Time lost adjusting settings

What are the benefits of precise taper settings?

Precise taper settings lead to higher quality outputs. They help in:

- Fewer errors during machining

- Longer tool life

- Better use of materials

Common Signs of Taper Adjustment Issues

Indicators that taper adjustment may be needed. Impact of these issues on finished workpieces.Several signs show that taper adjustment may be needed. Look for uneven or angled cuts in your work. If parts don’t fit together tightly, it’s a clear warning. You might also notice unusual wear on tools. These issues can ruin the look of your finished pieces.

- Uneven cuts: Changes in the shape of the cut surface.

- Poor fit: Parts not connecting smoothly.

- Tool wear: Signs of damage on your cutting tools.

These problems can lead to wasted materials and time. It’s important to check your lathe regularly. This ensures your projects turn out great!

How do you know if taper adjustment is needed?

Check for uneven cuts, poor fitting parts, or damaged tools. Any of these signs could mean it’s time to adjust the taper on your lathe.

Tools Required for Taper Adjustment

List of essential tools for performing adjustments. Description of how to use these tools effectively.To make taper adjustments on your lathe, having the right tools is essential. You’ll need a few specific items for the job. First, grab a caliper for measuring accuracy. Next, a wrench is crucial to tighten or loosen bolts without losing your grip – avoid those slippery fingers! Lastly, a leveling tool helps keep everything steady. Here’s a handy table to keep track of these tools:

| Tool | Purpose |

|---|---|

| Caliper | Measure taper accurately |

| Wrench | Tighten or loosen bolts |

| Leveling Tool | Ensure stability during adjustments |

Using these tools properly can save you time and effort. Keep them close by, and you’ll be making perfect adjustments in no time. Remember, practice makes perfect—unless you’re trying to make pancakes, then just don’t mix the batter too much!

Step-by-Step Guide to Adjusting Lathe Cross Slide Taper

Detailed procedure for assessing and adjusting taper settings. Tips for achieving optimal results during the adjustment process.Adjusting your lathe’s cross slide taper is important for precision work. First, check the taper setting by using a dial gauge on the slide. This gauge will help you measure if everything is aligned. If needed, loosen the screws on the taper adjuster and make small changes. Always check your results after each adjustment. Remember, even tiny tweaks can lead to big changes! Measure twice, adjust once!

| Tip | Description |

|---|---|

| Use a gauge | It helps you see where you need to adjust. |

| Make small adjustments | Little changes can make a huge difference! |

| Test frequently | Check your progress so you don’t go off track. |

Finally, don’t forget to celebrate your success—maybe with a funny dance, because adjusting a lathe is no small feat! Remember, practice makes perfect.

Maintaining Taper Settings for Longevity

Best practices for regular maintenance and inspection. Strategies to prevent future taper adjustment problems.Regular care for your lathe is like giving it a warm hug. Check the taper settings often to keep them in tip-top shape. Clean the cross slide frequently to remove dirt and grime. This helps prevent future taper adjustment headaches. A happy lathe works better and lasts longer!

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect Taper Settings | Every Week | Ensure they are precise! |

| Clean Cross Slide | Daily | Remove dust and chips! |

| Lubricate Moving Parts | Every Month | Keep things smooth! |

By sticking to these practices, you can avoid issues before they happen. Remember, it’s better to be proactive than reactive! As the saying goes, “An ounce of prevention is worth a pound of cure.” Do your lathe a favor, and keep it happy!

Troubleshooting Common Taper Adjustment Problems

Solutions to frequent issues encountered during adjustments. Advice on when to seek professional assistance.Adjusting the taper on your lathe can sometimes feel like solving a mystery. You might notice uneven cuts or odd shapes popping up that weren’t there before. One common issue is a misaligned cross slide, which can be fixed by checking the bolts and ensuring they’re snug. If the taper still looks wonky, it may be best to consult a pro. Remember, calling an expert can save you more time than guessing!

| Problem | Solution |

|---|---|

| Uneven Cuts | Check the cross slide alignment and tighten bolts. |

| Frequent Adjustments Needed | Inspect for wear and replace parts if necessary. |

| Stuck Taper Adjustment | Use lubricant to free up stiff components. |

Case Studies and Examples

Realworld scenarios illustrating successful taper adjustments. Analysis of lessons learned from past adjustments and errors.Learning from real experiences can be eye-opening. One workshop improved their lathe cross slide taper adjustment. They adjusted the angle, leading to precise cuts. Another case showed the impact of small errors. A slight miscalculation led to faulty parts. Here are key takeaways:

- Check measurements before finalizing adjustments.

- Document changes for future reference.

- Test modifications on less important projects first.

These examples highlight how careful planning and testing can prevent mistakes. Success requires learning from both victories and failures.

What are some effective taper adjustment strategies?

Effective taper adjustment strategies include double-checking measurements, using test pieces, and keeping a detailed record of changes made. This practice helps in achieving smoother and more accurate cuts.

Conclusion

In conclusion, adjusting the lathe cross slide taper is important for accurate machining. You can improve your work by knowing how to make these adjustments. Always check your machine’s manual for specific techniques. Don’t hesitate to practice on scrap material. Keep learning, and explore more resources on lathe maintenance to enhance your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cross Slide Taper Adjustment:Okay! Here are five questions about lathe cross slide taper adjustment. 1. What is a lathe? A lathe is a machine that spins metal or wood to shape it into different forms. 2. Why do we need to adjust the cross slide? We adjust the cross slide to make sure it cuts straight and makes the right shapes. 3. How do you know if the taper is off? You can tell by measuring the shapes it cuts. If they don’t match, it’s off. 4. What tools do you need to adjust the taper? You usually need a wrench, a ruler, and sometimes a dial gauge to help measure. 5. Can anyone make these adjustments? Yes! With a little practice and the right tools, you can learn to make these adjustments.

Sure! Please provide the question you’d like me to answer.

What Are The Common Signs That Indicate A Lathe Cross Slide Is Out Of Alignment And Requires Taper Adjustment?If the lathe cuts unevenly, that’s a sign the cross slide might be out of alignment. You might see the workpiece getting wider or narrower. If your tool leaves grooves instead of smooth lines, that’s another clue. Lastly, check if it makes strange noises while cutting. These signs mean it’s time to adjust the taper.

How Can You Determine The Correct Amount Of Taper Adjustment Needed For The Cross Slide On A Lathe?To find the right taper adjustment for the cross slide on a lathe, you can follow a simple process. First, measure the angle you need for your workpiece. Then, use a tool like a protractor to check your setting. Adjust the taper until it matches the angle you measured. Finally, test it on a scrap piece of material to make sure it cuts correctly.

What Tools Are Typically Required To Make Adjustments To The Cross Slide Taper On A Lathe?To adjust the cross slide taper on a lathe, you’ll need a few tools. First, grab an Allen wrench or a screw driver to loosen screws. Next, you might need a dial indicator to help measure your adjustments. Finally, keep a wrench handy to tighten everything back up when you finish. These tools will help you get the taper just right!

What Is The Process For Checking And Adjusting The Cross Slide Taper On A Precision Lathe?To check the cross slide taper on a precision lathe, you need a gauge or a measuring tool. First, we slide the tool along the cross slide to see if it makes straight lines. Then, we look for any gaps or mismatches. If we find them, we adjust screws on the lathe to make it straight again. Finally, we check it one more time to make sure it’s right.

How Does Improper Cross Slide Taper Adjustment Affect The Accuracy And Finish Of Machined Parts?If the cross slide taper adjustment is done wrong, it can mess up our work. The parts we make might not fit together well. They could also look rough or uneven. This means we need to be careful and adjust it correctly to make good, smooth parts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cross Slide Taper Adjustment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Okay! Here are five questions about lathe cross slide taper adjustment. 1. What is a lathe? A lathe is a machine that spins metal or wood to shape it into different forms. 2. Why do we need to adjust the cross slide? We adjust the cross slide to make sure it cuts straight and makes the right shapes. 3. How do you know if the taper is off? You can tell by measuring the shapes it cuts. If they don’t match, it’s off. 4. What tools do you need to adjust the taper? You usually need a wrench, a ruler, and sometimes a dial gauge to help measure. 5. Can anyone make these adjustments? Yes! With a little practice and the right tools, you can learn to make these adjustments.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Lathe Cross Slide Is Out Of Alignment And Requires Taper Adjustment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lathe cuts unevenly, that’s a sign the cross slide might be out of alignment. You might see the workpiece getting wider or narrower. If your tool leaves grooves instead of smooth lines, that’s another clue. Lastly, check if it makes strange noises while cutting. These signs mean it’s time to adjust the taper.”}},{“@type”: “Question”,”name”: “How Can You Determine The Correct Amount Of Taper Adjustment Needed For The Cross Slide On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right taper adjustment for the cross slide on a lathe, you can follow a simple process. First, measure the angle you need for your workpiece. Then, use a tool like a protractor to check your setting. Adjust the taper until it matches the angle you measured. Finally, test it on a scrap piece of material to make sure it cuts correctly.”}},{“@type”: “Question”,”name”: “What Tools Are Typically Required To Make Adjustments To The Cross Slide Taper On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the cross slide taper on a lathe, you’ll need a few tools. First, grab an Allen wrench or a screw driver to loosen screws. Next, you might need a dial indicator to help measure your adjustments. Finally, keep a wrench handy to tighten everything back up when you finish. These tools will help you get the taper just right!”}},{“@type”: “Question”,”name”: “What Is The Process For Checking And Adjusting The Cross Slide Taper On A Precision Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the cross slide taper on a precision lathe, you need a gauge or a measuring tool. First, we slide the tool along the cross slide to see if it makes straight lines. Then, we look for any gaps or mismatches. If we find them, we adjust screws on the lathe to make it straight again. Finally, we check it one more time to make sure it’s right.”}},{“@type”: “Question”,”name”: “How Does Improper Cross Slide Taper Adjustment Affect The Accuracy And Finish Of Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the cross slide taper adjustment is done wrong, it can mess up our work. The parts we make might not fit together well. They could also look rough or uneven. This means we need to be careful and adjust it correctly to make good, smooth parts.”}}]}