Have you ever used a lathe and found the crossfeed handwheel slipping? It can be frustrating, right? You might feel like your work is never going to end.

Imagine this: you’re in the middle of an important project. Suddenly, the handwheel starts slipping. This can lead to mistakes and wasted time. But don’t worry; you’re not alone in this challenge. Many people face this issue.

In this article, we’ll explore simple fixes for the lathe crossfeed handwheel slipping. You’ll learn tips that can help you get back on track fast. Did you know that a small adjustment can make a big difference? Get ready to dive in and discover easy solutions. Let’s take control of that handwheel together!

Lathe Crossfeed Handwheel Slipping Fix: Troubleshooting Tips

How to Fix Lathe Crossfeed Handwheel Slipping

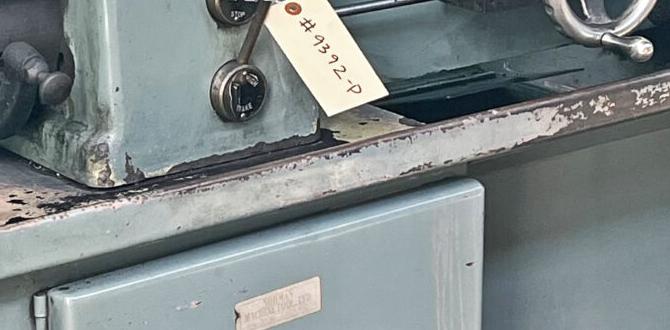

Lathe crossfeed handwheel slipping can be really frustrating. It happens when the handwheel loses grip, making it hard to control movements accurately. To fix this, check the set screws or tightening mechanisms. Sometimes, cleaning and lubricating the gears will help. Have you ever tried adjusting the tension? It could make all the difference! Knowing these steps can lead to smoother and more precise lathe operations, enhancing your woodworking experience. Don’t let a slipping handwheel slow you down!Understanding Lathe Crossfeed Handwheel Mechanism

Explanation of how the lathe crossfeed handwheel functions.. Common issues that lead to slipping and their implications on lathe operation..The lathe crossfeed handwheel is a simple gadget with a big job. It controls how the lathe moves left and right. This is important for making precise cuts. But sometimes, it may slip like a banana peel, leading to funky results. Common issues include loose connections or worn gears, which can really mess up your work. Fixing these is key, or you might end up with projects that look more ‘abstract art’ than ‘machined masterpiece’!

| Common Issues | Implications |

|---|---|

| Loose bolts | Unstable cutting, annoying slips |

| Worn gears | Increased wear and tear, bad cuts |

Identifying Symptoms of Slipping Handwheel

Key indicators that suggest the handwheel is slipping during operation.. Potential causes for the handwheel slipping, including wear and mechanical failures..A slipping handwheel can cause problems during lathe operation. You may notice these signs:

- The handwheel turns easily without moving the carriage.

- There are strange noises when operating the machine.

- The cutting speed seems uneven or slow.

Common reasons for slipping include:

– Wear and tear on the gears.

– Loose parts that need adjustment.

– Mechanical failures that require repair.

What are the symptoms of a slipping handwheel?

Look for signs like unusual sounds, easy movement without action, and inconsistent cutting speeds.

What causes handwheel slipping?

Common issues include worn gears, loose components, and mechanical failures.

Tools Required for Fixing Handwheel Slipping

List of essential tools and materials needed for the repair process.. Tips for selecting quality replacement components if necessary..To tackle the handwheel slipping, gather some basic tools. You’ll need a wrench set, screwdriver, and replacement parts. Don’t forget the trusty locktight—it keeps everything snug. A good flashlight helps you see into tight spots, and a clean cloth is great for wipe-downs. When choosing replacement parts, pick quality brands. You don’t want to end up with a handwheel that slips faster than a banana peel! Here’s a quick tool checklist:

| Tool | Use |

|---|---|

| Wrench Set | To loosen or tighten bolts |

| Screwdriver | To adjust screws |

| Replacement Parts | For fixing the handwheel |

| Locktight | To secure loose components |

| Flashlight | To illuminate dark areas |

| Clean Cloth | For cleaning surfaces |

With these tools, you’ll be ready to fix that pesky slipping handwheel in no time!

Step-by-Step Guide to Diagnose and Fix Slipping Handwheel

Detailed troubleshooting steps to identify the root cause of slipping.. Comprehensive instructions for adjustment and repairs..Is your lathe crossfeed handwheel slipping like a banana peel? Don’t worry! First, check for loose screws or nuts. Tighten them if needed! Next, examine the handwheel. If it’s too worn out, it may need a replacement. For a quick fix, try adjusting the tension. Use the table below for clear steps:

| Step | Action |

|---|---|

| 1 | Inspect screws |

| 2 | Check the handwheel |

| 3 | Tighten or replace as necessary |

| 4 | Adjust tension |

Following these steps should get your handwheel spinning smoothly again. Remember, if it still slips, it might be calling for a more serious repair, like an ancient magician seeking a spell! So, check twice, fix right, and keep turning with delight!

Preventive Maintenance Tips for Lathe Owners

Best practices to prevent future slipping issues with the crossfeed handwheel.. Importance of regular inspection and maintenance routines..Maintaining your lathe can save you from future headaches, like a slipping crossfeed handwheel. Start with regular checks. Inspect the handwheel often for dirt or wear. A little grime can turn it into a slippery monster! Keep it clean and oiled. You’ll thank yourself later when it works like a charm. Remember, routine care is like brushing your teeth; skip it, and you might face a big problem!

| Maintenance Task | Frequency |

|---|---|

| Inspect handwheel | Weekly |

| Clean and oil | Monthly |

| Check for wear | Every 3 months |

When to Seek Professional Help

Scenarios in which DIY repair may not be advisable.. Criteria for determining when to consult a professional machinist or technician..Sometimes, fixing things can be tricky. If you’re unsure about your lathe crossfeed handwheel, it might be time to call a pro. When the issue seems too complicated or risky, it’s better to seek help. If you hear strange noises or smell funny smells, don’t ignore them! Also, if your DIY tool feels more like a weapon than a helper, it’s time to back off. Knowing when to consult a technician can save you headaches (and maybe more). Here’s a simple guide:

| Signs to Seek Help | Why You Should |

|---|---|

| Complex Issues | Professionals have experience. |

| Strange Noises | They might signal danger. |

| Unusual Odors | They can mean trouble. |

| Feeling Unsafe | Your safety is priority! |

Remember, sometimes asking for help is smarter than trying to fix everything yourself. After all, why wear yourself out saving a few bucks?

Conclusion

In conclusion, fixing a slipping lathe crossfeed handwheel is important for smooth operation. First, check for loose screws and tighten them. Next, inspect the gears for wear and replace if needed. If problems continue, consider lubricating the components. You can explore more detailed guides online to help with repairs. Taking these steps will keep your lathe working better!FAQs

What Are The Common Causes Of A Lathe Crossfeed Handwheel Slipping During Operation?A lathe crossfeed handwheel can slip for a few reasons. First, dirt or grease can build up and make it slippery. Second, the handwheel might be loose or not tight enough. Third, worn-out parts can cause it to slip. We need to check these things to fix the problem.

How Can I Determine If The Slipping Issue Is Due To Wear And Tear Or Improper Adjustment?To find out if slipping is caused by wear and tear or improper adjustment, check the parts carefully. Look for signs of damage or wear, like cracks or loose bits. Then, see if the adjustments are tight and correct. If everything looks good and tight, it might be worn out. If something feels loose, you can try adjusting it to see if that helps!

What Tools And Materials Are Needed To Fix A Slipping Crossfeed Handwheel On A Lathe?To fix a slipping crossfeed handwheel on a lathe, you need a few tools and materials. First, get a screwdriver to open the housing. You’ll also need a wrench to tighten any loose parts. Some grease can help the parts slide smoothly. A clean rag is good for wiping away dirt.

Can Lubricants Or Greases Help Prevent The Slipping Of The Crossfeed Handwheel, And If So, What Types Are Recommended?Yes, lubricants or greases can help stop the crossfeed handwheel from slipping. You can use sticky greases, like lithium grease, because they stick well. Oil can work too but may not last as long. Make sure to apply just a little so it doesn’t get messy. Regularly checking and cleaning helps keep everything working smoothly.

Are There Any Specific Maintenance Practices I Should Adopt To Avoid Future Slipping Issues With The Lathe Crossfeed Handwheel?To avoid slipping with the lathe crossfeed handwheel, you should keep it clean. Wipe away any dust or dirt regularly. You can also check for any loose screws and tighten them if needed. Finally, make sure to lubricate it lightly with oil to help it move smoothly. This will help your lathe work better!