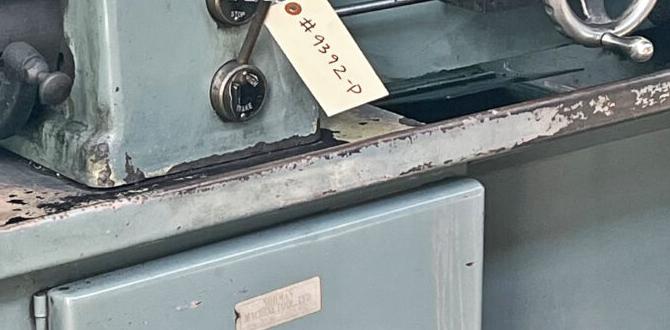

Have you ever wondered how those shiny stainless steel parts are made? One of the key players in this process is the lathe cutting tool. These tools shape and cut materials with precision, turning raw metal into brilliant products.

Imagine watching a skilled worker carefully carve a piece of stainless steel. That’s the magic of a lathe cutting tool at work! It spins the metal while sharp blades cut it exactly how the worker wants.

Did you know that stainless steel is popular because it resists rust and corrosion? This makes it a top choice for everything from kitchen utensils to car parts. But cutting stainless steel isn’t easy. You need the right tools to do it well. That’s where the lathe cutting tool shines.

This article will explore how lathe cutting tools make working with stainless steel easier. Get ready to learn about their features, types, and the best practices for using them! Who knows? You might find yourself inspired to try using one!

Choosing The Right Lathe Cutting Tool For Stainless Steel

Lathe Cutting Tool for Stainless Steel

Lathe cutting tools are vital for shaping stainless steel. They come in various types and are designed to slice through tough materials easily. Did you know that stainless steel is used in everyday items like cutlery and appliances? Choosing the right lathe tool can lead to smoother cuts and better finishes. Factors like tool material, angle, and coating greatly impact performance and durability. Using the right tool can turn a challenging job into a simple task!Understanding Stainless Steel

Properties of stainless steel that affect machining. Common applications of stainless steel in manufacturing.Stainless steel is a superstar in the manufacturing world. It’s strong, rust-resistant, and shiny like your favorite kitchen appliance. Its properties, like durability and corrosion resistance, can affect how we machine it. When cutting it with a lathe, tools must be sharp and strong to handle its toughness. If not, they might get a bit cranky! You can find stainless steel in everything from buildings to cutlery. Here’s a quick look at its common applications:

| Application | Description |

|---|---|

| Culinary Tools | Knives, forks, and pots that shine through every meal. |

| Construction | Used in beams and pipes for sturdy buildings. |

| Healthcare | Surgical instruments that are clean and safe. |

| Aerospace | Parts that fly high and need to be strong. |

In short, understanding stainless steel helps us use less time battling with it and more time appreciating its shine!

Material Composition of Cutting Tools

Types of materials used in cutting tools. Effects of material composition on performance with stainless steel.Cutting tools are made from different materials to help them slice through tough things like stainless steel. Common options include high-speed steel (HSS), carbide, and ceramics. Each has its own perks. For example, carbide is super tough and can handle high heat, making it great for stainless steel. In contrast, HSS is easier to sharpen but not as strong. Using the right material helps the tool stay sharp and last longer, like a superhero on a mission!

| Material | Benefits | Best Use |

|---|---|---|

| High-Speed Steel (HSS) | Easy to sharpen | General cutting |

| Carbide | Heat resistant | Hard materials |

| Ceramics | Very hard | Precision cutting |

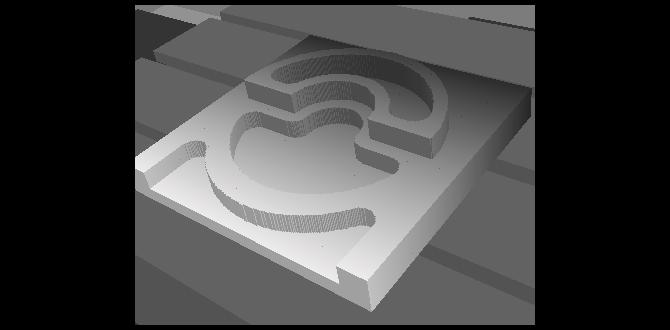

Tool Geometry and Design

Key geometric features of cutting tools. Importance of tool design in stainless steel machining.Understanding tool geometry is essential for cutting tools, especially when working with stainless steel. Key features include the cutting edge angle, which helps slice through tough materials, and the rake angle, which reduces friction and heat. A well-designed tool can make machining smoother and faster. If a tool’s design isn’t right, you might as well be trying to cut steel with a butter knife! Great design leads to better performance and longer tool life.

| Tool Feature | Importance |

|---|---|

| Cutting Edge Angle | Helps in slicing through materials efficiently. |

| Rake Angle | Reduces friction, which prevents overheating. |

| Relief Angle | Prevents the cutting edge from rubbing against work material. |

Coatings and Surface Treatments

Common coatings used on cutting tools. Benefits of coatings for stainless steel cutting.Cutting tools for stainless steel are often dressed to impress! Common coatings like titanium nitride (TiN) and diamond-like carbon (DLC) add flair and function. These shiny outfits improve durability and reduce friction, helping tools last longer and cut smoother. Imagine your cutting tool having a superhero cape that helps it tackle tough tasks!

| Coating | Benefits |

|---|---|

| TiN | Enhances hardness and reduces wear. |

| DLC | Minimizes friction and increases lifespan. |

By giving cutting tools these special outfits, we make them ready for a tough day at the workshop. It’s like putting on a helmet before bike riding—you want to stay safe and sound!

Tool Selection Criteria

Factors to consider when choosing a cutting tool. Cost versus performance analysis.Choosing the right tool can feel like picking your favorite ice cream flavor—pretty tough! Factors to consider include material type, cost, and performance. A lathe cutting tool for stainless steel must be tough enough to withstand pressure. Price matters, but don’t let it trick you; a cheaper tool might break easily and cost more in the long run. Here’s a quick table on cost versus performance:

| Tool Type | Cost | Performance |

|---|---|---|

| High Speed Steel | Low | Moderate |

| Carbide Tools | High | Very High |

| Ceramic Tools | Medium | High |

Remember, investing in a better tool can save you time and headaches! Happy cutting!

Tool Life and Maintenance

How to extend the life of lathe cutting tools. Maintenance techniques for optimal performance.Keeping your lathe cutting tools happy is key to their long life. First, clean them after each use like giving a tool a bubble bath. Regularly inspect for wear, and if you see chips or dull edges, it’s time for a little TLC. Use the right coolant too; no one likes a dry day! Here’s a simple table to help:

| Maintenance Task | Frequency |

|---|---|

| Clean Tools | After Each Use |

| Inspect for Wear | Weekly |

| Sharpen Edges | As Needed |

| Check Coolant | Before Each Use |

Follow these tips for optimal performance. Remember, a happy tool makes for a smooth job! If you keep them well, they’ll work hard for you, just like a good pet—minus the barking!

Best Practices for Machining Stainless Steel

Recommended machining techniques and parameters. Tips for reducing tool wear and improving finish quality.Machining stainless steel can be a bit tricky, but here are some nifty tips! Use a sharp lathe cutting tool for best results. Keep your cutting speed around 80 to 120 feet per minute; this is just fast enough to keep the party going without overheating. Coolant is your best friend—don’t skip it! A good coolant helps reduce tool wear and gives you that shiny finish you crave. Check out the table below for more details:

| Technique | Parameter |

|---|---|

| Cutting Speed | 80-120 ft/min |

| Feed Rate | 0.005-0.01 in/rev |

| Depth of Cut | 0.01-0.1 in |

To improve finish quality, make sure your tool is clean and well-maintained. A dull tool is like a sleepy sloth; it just won’t perform well. So stay sharp and have fun creating those stainless steel masterpieces!

Case Studies and User Experiences

Realworld applications and reviews. Lessons learned from machining stainless steel.Users have shared colorful stories about their adventures with lathe cutting tools for stainless steel. From simple projects to complex creations, they learned valuable lessons. Many found that using the right tool made a huge difference. One user jokingly said, “It’s like using a spoon to cut soup!”

| User | Experience | Lesson Learned |

|---|---|---|

| Alex | Made steel parts | Quality tools matter! |

| Sara | Created artwork | Patience pays off. |

| John | Built a bike frame | Measure twice, cut once! |

These experiences show that working with stainless steel can be tricky but fun. Overall, they remind us that the right tools and a little humor can make any project successful!

Future Trends in Lathe Cutting Tools

Innovations in technology and materials. Predictions for the future of machining stainless steel.The future of lathe cutting tools looks bright, especially for stainless steel. New technology is changing how we use these tools. For instance, smart sensors will help producers monitor cutting conditions. This means better performance and less waste.

Also, advanced materials are being developed for cutting tips. These materials can last longer and cut faster. This means less time and money spent on replacing tools!

- More automation in machining

- Use of Machine Learning for efficiency

- Eco-friendly materials for tool-making

These innovations promise a future where machining is quicker and more efficient. The industry can expect exciting changes ahead!

What innovations are shaping the future of lathe cutting tools?

Innovations like smart sensors and advanced materials are leading the way. These changes make tools last longer and perform better.

Future Directions in Machining Stainless Steel:

- Automation: Machines may work more on their own.

- AI and Learning: Tools will be smarter, adjusting cuts in real-time.

- Sustainability: More eco-friendly materials will come into use.

Conclusion

In summary, using a lathe cutting tool for stainless steel is essential for smooth, accurate work. You’ll need high-speed steel or carbide tools for the best results. Remember to keep your tools sharp and clean. We encourage you to practice using these tools and explore more about their features online. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cutting Tools For Stainless Steel:Sure! A lathe is a machine that helps us shape metal. Cutting tools are parts we use on a lathe to cut metal. When we work with stainless steel, we need strong cutting tools. They help us make smooth and precise shapes. It’s important to choose the right tool for the job!

Sure! Please provide the question you want me to answer, and I’ll be happy to help.

What Types Of Cutting Tools Are Most Effective For Machining Stainless Steel On A Lathe?When machining stainless steel on a lathe, we should use certain cutting tools. High-speed steel (HSS) tools work well and last a long time. Carbide tools are even better because they stay sharp longer. We can also use ceramic tools for special jobs. These tools help us cut the metal smoothly.

How Do Commercial Coatings On Lathe Cutting Tools Enhance Performance When Machining Stainless Steel?Commercial coatings on lathe cutting tools help them cut stainless steel better. These special layers make the tools last longer. They also reduce friction, so the tools don’t get too hot. When tools stay cooler, they work faster and can cut more smoothly. This means you get better results when making things from stainless steel.

What Are The Recommended Cutting Speeds And Feeds For Lathe Operations Involving Stainless Steel?When you work with stainless steel on a lathe, you need to cut carefully. A good speed is around 80 to 120 feet per minute. For the feed, you might use about 0.005 to 0.020 inches per revolution. Always start slow and adjust if needed. This helps you make a nice cut without damaging your tools.

How Does Tool Geometry Affect The Cutting Performance And Precision In Stainless Steel Machining?Tool geometry is how a cutting tool is shaped. When we use a tool with the right shape, it cuts stainless steel more easily. A good shape helps us make cleaner cuts and sharp edges. If the tool shape is wrong, it can break or make rough cuts. So, having the right tool shape helps us work better and makes our projects look nicer.

What Maintenance Practices Should Be Followed To Prolong The Life Of Lathe Cutting Tools Used For Stainless Steel?To help lathe cutting tools last longer when working with stainless steel, keep them clean. After each use, wipe off any dirt and grease. You should check the tools for any damages or wear. If you see any dull spots, sharpen them right away. Finally, store the tools in a dry place to prevent rust.