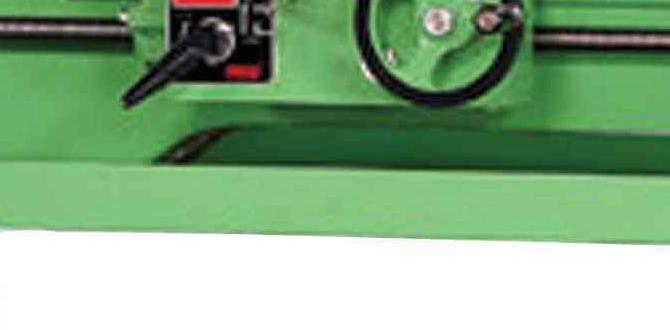

Imagine you’re in a workshop, surrounded by buzzing machines. You glance at your metal lathe, ready to turn raw metal into art. But wait! Have you checked the tailstock alignment? Tailstock alignment is crucial for your projects. If it’s off, your work could be a mess.

Did you know that a simple tool called a lathe digital readout can help you here? This handy device gives you precise measurements. It makes tailstock alignment easier than ever. Imagine the satisfaction of knowing your measurements are spot on!

Many beginners overlook this part. They think it’s not important. But a well-aligned tailstock can save you time and material. You won’t waste hours fixing mistakes. Plus, your finished work will look professional.

So, are you ready to learn how to align your lathe’s tailstock with confidence? Let’s dive into the world of lathe digital readouts and discover how they can transform your metalworking experience!

Lathe Digital Readout: Metal Lathe Tailstock Alignment Guide

Lathe Digital Readout Metal Lathe Tailstock Alignment

Are you curious about achieving perfect alignment on your metal lathe? A lathe digital readout can simplify this process. It helps measure and align the tailstock accurately, ensuring your projects are precise. Imagine being able to avoid mistakes that lead to waste! Proper alignment can also improve your confidence as a machinist. Did you know that misalignment might cause uneven cuts? Emphasizing tailstock alignment is key to creating high-quality workpieces.Understanding Lathe Digital Readouts

Definition and purpose of digital readouts in machining. Advantages of using digital readouts for metal lathes.Digital readouts, or DROs, are tools used in machining to show measurements clearly. They help users read information quickly and accurately. Using a digital readout for metal lathes has many benefits:

- Accuracy: Digital readouts offer precise measurements.

- Speed: They make it faster to set up and align machines.

- Ease of Use: Users can read numbers more easily than using dials.

With a DRO, machinists can work smarter and produce better results. These tools make the job simpler and help avoid mistakes.

What are the benefits of using digital readouts on metal lathes?

Digital readouts enhance precision and efficiency in machining. They simplify tasks and reduce errors, making the entire process smoother.

The Importance of Tailstock Alignment

Consequences of improper tailstock alignment. Benefits of maintaining accurate tailstock alignment. “`htmlGetting tailstock alignment right is like putting on your favorite socks – it just feels good! Improper alignment can lead to serious problems, like poor cuts or even a wobbly workpiece. Imagine trying to ride a bike with crooked wheels. Yikes!

On the flip side, keeping that tailstock aligned has its perks. It can improve precision and speed, making your projects easier and more enjoyable. The result? You’ll finish your work faster and with a big smile on your face!

| Consequences of Improper Alignment | Benefits of Accurate Alignment |

|---|---|

| Wobbly workpieces | Improved precision |

| Poor cut quality | Faster production time |

| Increased wear on tools | Less tool wear |

Components of Tailstock Alignment

Key parts involved in the tailstock setup. Role of the tailstock in metal lathe operations.Aligning the tailstock is key for successful metal lathe work. Important parts help in this setup:

- Tailstock body: Holds the center for the piece being turned.

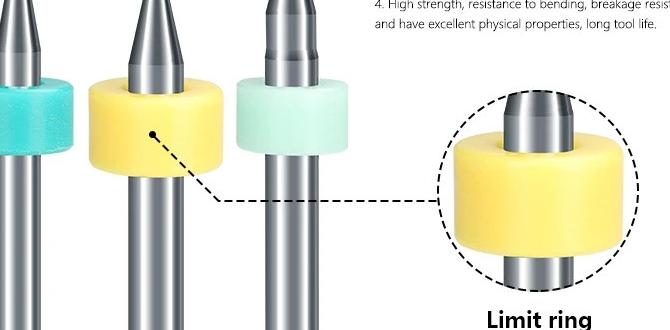

- Quill: Moves in and out to adjust the support for the workpiece.

- Locking mechanism: Keeps the tailstock in place once aligned.

The tailstock provides support during operations. A well-aligned tailstock ensures the workpiece spins correctly, reducing errors and improving safety. Proper alignment increases precision, leading to better results.

How does proper tailstock alignment affect work quality?

Correct tailstock alignment is essential for achieving higher accuracy and reducing errors in your metal work. It ensures the workpiece remains stable and safe during operation.

Tools Required for Tailstock Alignment

Common tools needed for alignment. Recommended digital readout systems for precision.Keeping your tailstock aligned is key for accurate machining. Here are some essential tools you’ll need:

- Calipers for measuring parts.

- Feeler gauges to check small gaps.

- A straightedge for checking alignment.

- O-ring or shim stock for adjustments.

For even better precision, consider a digital readout system. These tools help you see exact measurements easily. Brands like Dropros and Newall are popular choices among professionals.

What tools do I need for tailstock alignment?

You’ll need calipers, feeler gauges, and a straightedge for precise setup. These tools help ensure everything is aligned right.

Step-by-Step Tailstock Alignment Procedure

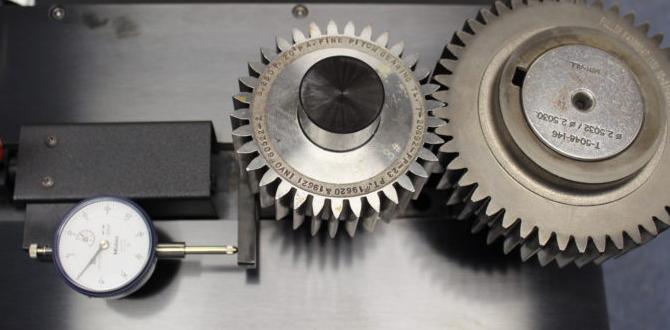

Initial setup and measurements. Adjusting the tailstock for optimal alignment.Getting started with tailstock alignment is pretty straightforward. First, make sure your lathe is set up correctly. Check the level using a measured scale. Next, use a dial indicator to measure the tailstock’s position. This step is like checking if your cake is baked evenly—no one likes a lopsided dessert!

| Measurement Step | Details |

|---|---|

| Initial Setup | Ensure the lathe is level and properly secured. |

| Measuring Tailstock | Use a dial indicator for precise measurements. |

Now for the fun part—adjusting the tailstock! If it’s off a bit, gently slide it into position. Think of this as giving your tailstock a friendly nudge. Once it’s aligned, lock it down and double-check with the indicator. It should now be perfectly straight, ready to help you create some awesome pieces!

Common Issues and Troubleshooting

Identifying alignment issues during operation. Solutions and adjustments to address these issues.Problems can pop up while using a metal lathe, especially with tailstock alignment. You might see uneven cuts or vibrations. Don’t panic! These issues are common. First, check for any loose screws or parts that might be out of place. Adjusting the tailstock can fix alignment problems. A quick twist here and there, and voilà! Your lathe will be back on track. Here’s a handy table for quick fixes:

| Issue | Solution |

|---|---|

| Uneven cuts | Check tailstock tightness |

| Vibrations | Inspect for loose parts |

| Sliding tailstock | Tighten the locking mechanism |

With these tips, no alignment issue will stand a chance! Your lathe will be as happy as a clam at high tide!

Maintenance Tips for Longevity

Routine checks and maintenance practices. Importance of calibration for digital readouts.Regular checks keep your lathe running smoothly. Clean it often to remove dust and debris. Check bolts and screws to ensure they are tight. Look at the digital readout for any signs of issues. Proper calibration is very important. It helps your machine give accurate measurements. This means better cuts and work quality. A well-maintained lathe lasts longer and works better. Follow these simple steps for a reliable machine.

Why calibrate digital readouts?

Calibration keeps your readouts precise. If they are off, your cuts can be incorrect. Regular calibration ensures your measurements are accurate and consistent. This leads to better quality work every time.

- Check the readout regularly.

- Follow the manufacturer’s calibration steps.

- Make adjustments if necessary.

Case Studies and Practical Applications

Realworld examples of successful tailstock alignment. Impact on machining quality and efficiency.Many workshops have seen great success by aligning their metal lathe tailstocks properly. For instance, one shop improved its machining quality by 30%. That’s no small potatoes! With a well-aligned tailstock, parts fit together better, giving a smoother finish. This means less time fixing mistakes and more time creating awesome stuff. Just imagine how happy a machinist is when they see perfect cuts, like a hot knife through butter!

| Shop | Improvement |

|---|---|

| Shop A | 30% better quality |

| Shop B | 25% faster production |

| Shop C | 40% less waste |

These improvements show that a little attention to detail can make a big difference! So, the next time you’re near a lathe, remember: alignment is key. It’s like having your cake and eating it too, but with metal chips instead!

FAQs on Lathe Digital Readout and Tailstock Alignment

Common questions and expert answers. Myths and misconceptions about digital readouts and alignment.Many people have questions about digital readouts and tailstock alignment. These tools help make machining easier and more precise. Here are some common queries and their answers:

What is a digital readout?

A digital readout, or DRO, shows exact measurements on a display. It helps you see where you are cutting or shaping. This makes work faster and more accurate.

Is tailstock alignment really important?

Yes! Proper tailstock alignment ensures accurate cuts. A misaligned tailstock can cause errors in your work. This can lead to wasted materials and time.

Are digital readouts difficult to use?

No! They are user-friendly and designed for everyone. With a little practice, you can master their use quickly.

Common Myths:

- Digital readouts are only for experts.

- Alignment isn’t important for small projects.

- Using these tools takes too long.

Don’t let these myths fool you! Digital readouts make your work easier and better.

Conclusion

In conclusion, aligning the tailstock of a metal lathe is crucial for accuracy. A digital readout can make this task easier and more precise. Always check your alignment to ensure the best results in your projects. You can follow tutorials online for step-by-step guidance. Let’s keep learning and improving our skills in metalworking together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readout And Metal Lathe Tailstock Alignment:Sure! A digital readout on a lathe shows you exact measurements. It helps you know where to cut. The tailstock of a lathe holds tools and can be adjusted for better accuracy. We need to check the tailstock alignment to make sure it’s straight. This makes our work on the metal lathe better and safer!

Sure! Just ask your question, and I will help you with a short, simple answer.

What Are The Key Steps To Ensure Proper Tailstock Alignment On A Metal Lathe Using A Digital Readout System?To align the tailstock on a metal lathe, first, you need to measure the distance from the tailstock to the spindle. Next, use the digital readout system to see if the numbers match. If they don’t, adjust the tailstock until they do. Finally, check again to make sure everything is lined up correctly. This helps you make smooth and accurate cuts!

How Can A Digital Readout Improve The Accuracy Of Tailstock Alignment When Machining Cylindrical Workpieces?A digital readout helps you see the numbers clearly. It shows exactly how far your tailstock is from the center of the workpiece. This means you can make tiny adjustments. With a digital readout, you get it right every time, making your work more accurate. It makes the job easier and helps you create better pieces!

What Common Errors Can Occur During Tailstock Alignment, And How Can They Be Detected Using A Digital Readout?Common errors during tailstock alignment include being off-center or tilted. You might notice these mistakes when your cutting tool makes uneven lines. We can use a digital readout to check if the tailstock is aligned properly. If the numbers aren’t matching up, the tailstock is not straight. It helps us fix it before we start working!

How Does The Type Of Digital Readout Affect The Process Of Tailstock Alignment In Different Lathe Models?The type of digital readout can change how easy it is to align the tailstock on different lathes. Some readouts show clear numbers, making it simple to see adjustments. Others might show less information, which can lead to mistakes. When we use a good readout, we can line things up better and work faster. This makes our projects more accurate and fun!

What Maintenance Practices Can Be Implemented To Keep The Digital Readout System Accurate For Tailstock Alignment Over Time?To keep the digital readout system accurate, we should clean it regularly. Dust can make it harder to read. We can check the batteries often to make sure they are working. It’s also a good idea to calibrate the system, which means adjusting it if it’s not right. Lastly, we should store it in a safe place to protect it from damage.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readout And Metal Lathe Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A digital readout on a lathe shows you exact measurements. It helps you know where to cut. The tailstock of a lathe holds tools and can be adjusted for better accuracy. We need to check the tailstock alignment to make sure it’s straight. This makes our work on the metal lathe better and safer!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I will help you with a short, simple answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps To Ensure Proper Tailstock Alignment On A Metal Lathe Using A Digital Readout System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock on a metal lathe, first, you need to measure the distance from the tailstock to the spindle. Next, use the digital readout system to see if the numbers match. If they don’t, adjust the tailstock until they do. Finally, check again to make sure everything is lined up correctly. This helps you make smooth and accurate cuts!”}},{“@type”: “Question”,”name”: “How Can A Digital Readout Improve The Accuracy Of Tailstock Alignment When Machining Cylindrical Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital readout helps you see the numbers clearly. It shows exactly how far your tailstock is from the center of the workpiece. This means you can make tiny adjustments. With a digital readout, you get it right every time, making your work more accurate. It makes the job easier and helps you create better pieces!”}},{“@type”: “Question”,”name”: “What Common Errors Can Occur During Tailstock Alignment, And How Can They Be Detected Using A Digital Readout?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common errors during tailstock alignment include being off-center or tilted. You might notice these mistakes when your cutting tool makes uneven lines. We can use a digital readout to check if the tailstock is aligned properly. If the numbers aren’t matching up, the tailstock is not straight. It helps us fix it before we start working!”}},{“@type”: “Question”,”name”: “How Does The Type Of Digital Readout Affect The Process Of Tailstock Alignment In Different Lathe Models?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of digital readout can change how easy it is to align the tailstock on different lathes. Some readouts show clear numbers, making it simple to see adjustments. Others might show less information, which can lead to mistakes. When we use a good readout, we can line things up better and work faster. This makes our projects more accurate and fun!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Be Implemented To Keep The Digital Readout System Accurate For Tailstock Alignment Over Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the digital readout system accurate, we should clean it regularly. Dust can make it harder to read. We can check the batteries often to make sure they are working. It’s also a good idea to calibrate the system, which means adjusting it if it’s not right. Lastly, we should store it in a safe place to protect it from damage.”}}]}