Are you fascinated by how machines work? Have you ever wondered how to make a lathe function even better? If you have a lathe, you might be curious about the importance of dovetail slide gib tuning. Proper tuning can improve precision and make your projects more enjoyable.

Imagine trying to carve a perfect shape but your machine wiggles or slips. Frustrating, right? With the right adjustments, you can avoid that hassle. Dovetail slides play a crucial role in this process. They keep parts of the lathe moving smoothly.

Many people overlook these small details. However, tuning your gib can enhance your machine’s overall performance. Did you know that a small tweak can make a big difference? Learning the basics of dovetail slide gib tuning can unlock your lathe’s full potential.

Join us on this journey to understand how to fine-tune your lathe. With simple steps and tricks, you’ll be on your way to creating flawless designs. Let’s dive into the world of lathe tuning together!

Lathe Dovetail Slide Gib Tuning: Enhance Precision & Performance

Lathe Dovetail Slide Gib Tuning Explained

Adjusting the lathe dovetail slide gib is key for smooth operation. Proper tuning ensures better accuracy and helps your projects turn out just right. Did you know a well-tuned gib can reduce wear and extend the life of your machine? By regularly checking and fine-tuning these parts, you can avoid costly repairs. This simple task can lead to impressive improvements in your work. Ready to take your lathe skills to the next level?Understanding Dovetail Slides in Lathes

Definition and purpose of dovetail slides. Importance of precise tuning for lathe performance.Dovetail slides are key parts in lathes that help move tools smoothly and accurately. They fit together like a dovetail joint in woodworking—strong and stable! Precise tuning of these slides boosts lathe performance, making sure your projects turn out just right. Imagine trying to cut a straight line with a wobbly knife; that’s what it feels like without proper tuning! So, keep those slides in tip-top shape for a smooth ride!

| Feature | Importance |

|---|---|

| Smooth Movement | Ensures accuracy in cuts |

| Stability | Prevents tools from drifting |

| Longevity | Reduces wear and tear |

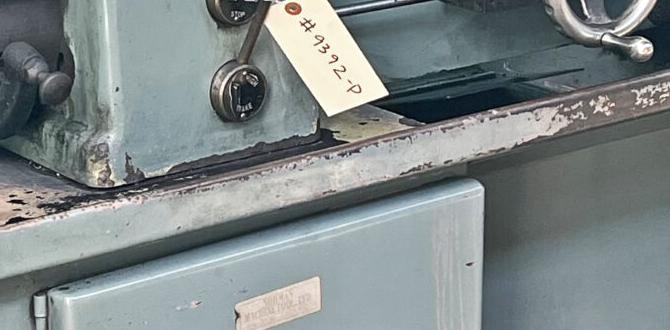

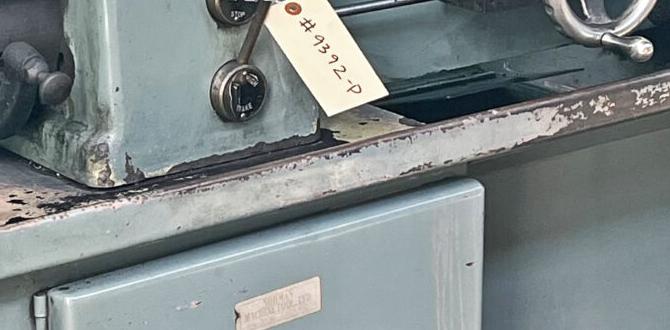

Common Issues with Dovetail Slides

Identifying wear and tear in lathe dovetail slides. Consequences of poor gib adjustment on machining accuracy.Worn-out dovetail slides can create big headaches for lathe users. Look for gaps or rough spots—these are signs of wear and tear. If your slide feels wobbly, it’s time to check! Poor gib adjustments lead to bad machining accuracy, making your projects go from perfect to “oops!” A small misalignment can turn a smooth cut into a bumpy ride. Here’s a quick look at some common issues:

| Issue | Signs to Look For | Consequences |

|---|---|---|

| Wear & Tear | Visible gaps, roughness | Poor finish, inaccurate cuts |

| Poor Gib Adjustment | Wobbling, uneven movement | Loss of accuracy, wasted material |

Maintaining your dovetail slides is like feeding your pet—ignore it, and it’ll cause chaos! Regular checks can save time and money.

Tools Required for Gib Tuning

Essential tools for accurate measurement and adjustment. Recommended products and brands for optimal results.Getting the right tools is like having the secret sauce for success. For gib tuning, you need a few trusty companions. A good caliper helps measure gaps with precision. A torque wrench ensures you don’t overdo it when tightening screws. Don’t forget a feeler gauge for checking clearances. Brands like Starrett and Mitutoyo make reliable tools that even your teacher would approve of. Here’s a quick look at some recommended tools:

| Tool | Recommended Brand |

|---|---|

| Caliper | Mitutoyo |

| Torque Wrench | Snap-On |

| Feeler Gauge | Starrett |

With these tools in hand, you’re ready to master gib tuning like a pro. Remember, even the best chefs need the right knives! Happy tuning!

Step-by-Step Guide to Tuning Dovetail Slides

Preparing the lathe for tuning. Detailed methods for adjusting the gib and slide.Before you dive into tuning your lathe, make sure it’s clean and ready to go. Dust bunnies don’t make the best helpers! Start by loosening the gib screws slightly. This helps the dovetail slide move freely. Next, use a feeler gauge to check the gaps. A perfect fit is key. Adjust the gib until it hugs the slide like a warm blanket. If you hear a squeak, it’s time for a little more TLC.

| Tools Needed | Steps to Adjust |

|---|---|

| Feeler gauge | Loosen gib screws |

| Screwdriver | Check gaps |

| Lubricant | Adjust gib for fit |

Remember, tuning is not just about turning screws. It’s about making your lathe work like a charm! Keep practicing, and soon you’ll be a tuning pro!

Testing and Verifying Adjustments

Techniques for checking precision after adjustments. Tools and methods for ensuring optimal performance.Once you’ve made adjustments, it’s time to ensure everything is just right. Think of it as tuning a musical instrument; you want that perfect sound! Start with a caliper to check distances accurately. A precision level will help to check if everything is balanced. Use a feeler gauge to measure tiny gaps—think of it as checking for “sneaky” spaces! After testing, always note your findings with a fun chart to track progress.

| Tool | Purpose |

|---|---|

| Caliper | Measures distances |

| Precision Level | Checks balance |

| Feeler Gauge | Measures gaps |

Maintenance Tips for Longevity of Dovetail Slides

Routine checks and cleaning procedures. Best practices to prevent wear and extend life span.Keeping dovetail slides in top shape is like giving your favorite toy some TLC. Regular checks are like a health check-up. Make cleaning a fun routine—think of it as dusting off your superhero! Wipe down with a soft cloth and ensure no grime builds up. Use a tiny amount of oil to keep things smooth. Too much oil, though, is like too much pizza—great but can lead to a mess! Check the numbers in the table below to guide your maintenance:

| Routine Check Frequency | Cleaning Method | Best Practices |

|---|---|---|

| Weekly | Soft cloth wipe | Store in a dry place |

| Monthly | Check for wear | Use light oil sparingly |

| Yearly | Deep clean | Inspect for damage |

By sticking to these steps, you’re basically a wizard, casting spells of longevity on your dovetail slides!

Advanced Tuning Techniques for Professionals

Customizing gibs for specific machining needs. Exploring advanced tuning methods for enhanced precision.Fine-tuning your lathe’s gib is like adjusting your favorite chair—it makes everything smoother! Each machine has unique needs. By customizing the gibs, you can match your specific machining tasks. You want a snug fit, but not something that makes you scream. Advanced tuning methods can boost your cutting precision. Don’t just wing it; tinkering with gib adjustments can make a big difference!

| Technique | Benefits |

|---|---|

| Gib Adjustment | Tighter fits for improved stability |

| Wear Correction | Less play in moving parts |

| Lubrication | Smoother operation and longer life |

Remember, precision is key! As the saying goes, “Measure twice, cut once!” Keeping your machine finely tuned will save you time and headaches!

Conclusion

In summary, tuning the dovetail slide gib on a lathe is crucial for smooth operation. A well-tuned gib reduces friction and improves accuracy. You should regularly check and adjust the gib to maintain performance. For better results, read more about lathe maintenance and practice tuning techniques. This simple task can enhance your lathe experience significantly!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Dovetail Slide Gib Tuning:Sure! Here are five questions about tuning the lathe dovetail slide gib. 1. What is a dovetail slide on a lathe? A dovetail slide helps the tool move smoothly. It keeps everything steady while you work. 2. Why do we need to tune the gib? Tuning the gib makes sure the tool moves easily. It helps you create better projects without any bumps. 3. How do you know when the gib needs tuning? If the tool feels loose or sticky, it’s time to tune the gib. You want it to move just right. 4. What tools do you need for tuning? You’ll need a wrench and maybe a screwdriver. These tools help adjust the parts to fit better. 5. How often should you tune the gib? You should check the gib regularly, especially if you use the lathe a lot. A little tuning keeps everything running smoothly!

Sure! Please give me the question you’d like me to answer.

What Are The Key Signs That Indicate A Need For Tuning The Dovetail Slides On A Lathe?You might need to tune the dovetail slides on your lathe if you notice the following signs. First, if the tool holder moves too easily or too hard, it’s a sign. Second, if your cuts are not straight or smooth, that’s another clue. Lastly, if you see gaps between the slides or parts don’t fit well, it’s time to check. Adjusting the dovetail slides will help your lathe work better!

How Do You Properly Measure The Gib Clearance On A Lathe’S Dovetail Slides During The Tuning Process?To measure the gib clearance on a lathe’s dovetail slides, start by cleaning the slides. Then, use a thin piece of paper or a feeler gauge to check the gap. Slide the paper between the parts and gently pull it out. You want a little drag, but if it pulls out easily, you need to adjust it. Keep testing until you have the right tightness!

What Materials Are Typically Recommended For Making A Gib, And How Does This Affect Tuning Accuracy?To make a gib, we usually use materials like wood, metal, or plastic. Wood is light and easy to shape. Metal makes it strong but can be heavier. The material you choose can affect how well the gib holds its tune. If you use a stable material, it will stay in tune better.

What Techniques Can Be Used To Ensure Even Pressure And Alignment When Adjusting The Gib Screws On A Lathe?To make sure the gib screws on a lathe are adjusted evenly, you can follow some easy steps. First, loosen all the screws a little bit. Then, tighten them in a pattern, like across or in a circle. Check the machine after each turn to see if everything is aligned correctly. Finally, keep adjusting until everything feels smooth and even.

How Often Should The Dovetail Slide Gibs Be Tuned And Inspected For Optimal Lathe Performance?You should check the dovetail slide gibs on your lathe every few months. If you notice any problems, look at them sooner. Cleaning and adjusting them helps the lathe work better. Regular checks keep your lathe running smoothly. Remember, a well-tuned machine is safer and more fun to use!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Dovetail Slide Gib Tuning:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about tuning the lathe dovetail slide gib. 1. What is a dovetail slide on a lathe? A dovetail slide helps the tool move smoothly. It keeps everything steady while you work. 2. Why do we need to tune the gib? Tuning the gib makes sure the tool moves easily. It helps you create better projects without any bumps. 3. How do you know when the gib needs tuning? If the tool feels loose or sticky, it’s time to tune the gib. You want it to move just right. 4. What tools do you need for tuning? You’ll need a wrench and maybe a screwdriver. These tools help adjust the parts to fit better. 5. How often should you tune the gib? You should check the gib regularly, especially if you use the lathe a lot. A little tuning keeps everything running smoothly!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Signs That Indicate A Need For Tuning The Dovetail Slides On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might need to tune the dovetail slides on your lathe if you notice the following signs. First, if the tool holder moves too easily or too hard, it’s a sign. Second, if your cuts are not straight or smooth, that’s another clue. Lastly, if you see gaps between the slides or parts don’t fit well, it’s time to check. Adjusting the dovetail slides will help your lathe work better!”}},{“@type”: “Question”,”name”: “How Do You Properly Measure The Gib Clearance On A Lathe’S Dovetail Slides During The Tuning Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure the gib clearance on a lathe’s dovetail slides, start by cleaning the slides. Then, use a thin piece of paper or a feeler gauge to check the gap. Slide the paper between the parts and gently pull it out. You want a little drag, but if it pulls out easily, you need to adjust it. Keep testing until you have the right tightness!”}},{“@type”: “Question”,”name”: “What Materials Are Typically Recommended For Making A Gib, And How Does This Affect Tuning Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a gib, we usually use materials like wood, metal, or plastic. Wood is light and easy to shape. Metal makes it strong but can be heavier. The material you choose can affect how well the gib holds its tune. If you use a stable material, it will stay in tune better.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Ensure Even Pressure And Alignment When Adjusting The Gib Screws On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure the gib screws on a lathe are adjusted evenly, you can follow some easy steps. First, loosen all the screws a little bit. Then, tighten them in a pattern, like across or in a circle. Check the machine after each turn to see if everything is aligned correctly. Finally, keep adjusting until everything feels smooth and even.”}},{“@type”: “Question”,”name”: “How Often Should The Dovetail Slide Gibs Be Tuned And Inspected For Optimal Lathe Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the dovetail slide gibs on your lathe every few months. If you notice any problems, look at them sooner. Cleaning and adjusting them helps the lathe work better. Regular checks keep your lathe running smoothly. Remember, a well-tuned machine is safer and more fun to use!”}}]}