Have you ever wondered how metal pieces are shaped with such precision? The answer often lies with a lathe floor mount metal lathe. This incredible machine turns raw metal into beautiful shapes and parts. It’s a tool that makers and builders love.

Imagine a piece of metal spinning while a sharp tool slices away at it. That’s what a lathe does! It helps create everything from simple table legs to complex engine parts. Using a lathe can feel like magic, turning flat metal into something useful.

Did you know that the basic design of a lathe has been around for thousands of years? Ancient craftsmen used it to make tools and weapons. Today, with a floor mount metal lathe, we can do so much more. It brings creativity to life in workshops everywhere.

If you’re interested in crafting, consider how a lathe could enhance your projects. Are you ready to explore the world of metalworking? Let’s dive deeper into the fun and fascinating world of floor mount metal lathes!

Exploring The Benefits Of A Lathe Floor Mount Metal Lathe

Understanding the Lathe Floor Mount Metal Lathe

The lathe floor mount metal lathe is a powerful tool for shaping metal. It allows users to create precise cuts and beautiful designs. Imagine crafting your own metal parts at home! These lathes support heavier workloads, ensuring accuracy and stability. A fun fact: many skilled makers began their journey with a lathe. With the right techniques, anyone can turn raw metal into stunning pieces of art. Why wait? Dive into the world of metalworking today!What is a Lathe Floor Mount Metal Lathe?

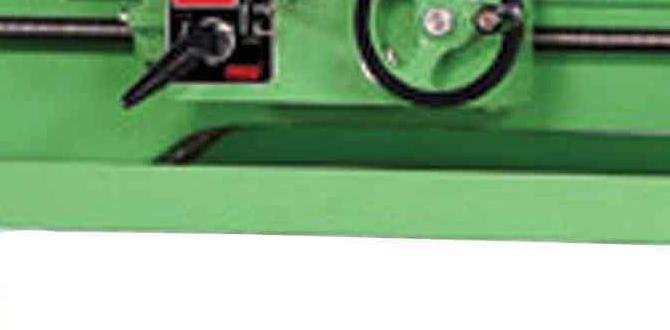

Definition and purpose of a floor mount metal lathe. Key features and components.A floor mount metal lathe is a machine that shapes and cuts metal. Think of it as a giant pencil sharpener, but instead of wood, it works with metal! Its main purpose is to create precise shapes and sizes for metal parts.

This machine has key features and components that make it special. The bed holds everything in place, while the headstock contains the motor and spindle. There’s also a tailstock that helps support the metal. Trust me, it’s like a metal spa day, where the lathe works its magic!

| Component | Function |

|---|---|

| Bed | Supports all parts |

| Headstock | Holds the spindle and motor |

| Tailstock | Provides support for the workpiece |

In short, a floor mount metal lathe is crucial for making metal parts. It’s like a superhero of machines, saving the day with precision and skill!

Key Features to Consider

Spindle speed and power options. Size, weight, and stability factors. Tooling and accessory compatibility.Choosing the right lathe means looking at a few key features. First, check spindle speed and power. A powerful spindle helps you cut through tough materials easier. Size and weight matter too. A stable lathe keeps you from wobbling when working, making it safer. Lastly, be sure your tools fit. Compatibility with accessories means less hassle and more fun! Remember, a happy lathe makes happy projects!

| Feature | Importance |

|---|---|

| Spindle Speed | Faster cuts |

| Weight | Stability |

| Tool Compatibility | Less hassle |

Benefits of Floor Mount Metal Lathes

Enhanced workspace and efficiency. Improved precision and accuracy for machining tasks. Durability and longevity in heavyduty projects.Floor mount metal lathes offer many advantages. They create an enhanced workspace by providing more room for tools and materials. This larger area boosts your efficiency in projects. These machines also improve precision and accuracy, making it easier to create exact parts. Their sturdy design ensures they can handle heavy-duty projects for a long time without breaking down.

What are the benefits of using a floor mount metal lathe?

Using a floor mount metal lathe allows for better workspace organization, greater accuracy, and long-lasting durability.

- Efficient Work Area: More space helps get things done faster.

- High Precision: Makes creating parts easy and exact.

- Durability: Built to last through tough tasks.

Maintenance and Care

Routine maintenance tips to extend lifespan. Common issues and troubleshooting.To keep your lathe in great shape, follow some simple care tips. Regularly check for loose bolts, clean the machine, and oil moving parts. This helps your lathe last longer. If you notice strange noises or uneven cuts, don’t ignore them. These can signal issues. Fixing small problems quickly can save time and money.

- Check oil levels monthly.

- Inspect tool condition often.

- Clean chips and dust regularly.

What are common problems with lathes?

Common problems include noise, vibration, and misalignment. Fixing them right away helps keep your lathe running smoothly.

Popular Brands and Models

Review of top brands in the market. Comparison of popular model specifications and user feedback.Many brands make great lathe floor mount metal lathes. Each brand has unique features. Below are some top brands and models in this market:

- Craftsman: Known for durability and ease of use. Good for beginners.

- Grizzly: Offers a variety of sizes. Users praise their power and precision.

- Jet: Reliable with advanced features. Great for professionals.

Reviews show that users love the power of these models. They say strong motors and smooth operation make work easy. Always check reviews to find the best fit for your needs.

What Makes These Brands Popular?

Good quality and user-friendly design are key reasons. Happy users often share their success stories, encouraging others to try these brands.

Cost Considerations

Factors affecting the price of floor mount metal lathes. Budgeting tips for purchasing.Buying a floor mount metal lathe? It’s fun but can feel like shopping for a pet dinosaur! Prices can vary. Factors like size, brand, and features matter. A durable model might cost more but could last longer than your cousin’s “quick fix” toy. Here’s a simple table to guide your budget:

| Factor | Price Range ($) |

|---|---|

| Basic Model | 300 – 700 |

| Mid-range | 700 – 2000 |

| High-end | 2000 – 5000+ |

To save money, consider buying used or look for sales. You’ll be spending less and maybe even have enough left for ice cream. Always remember, a good lathe is worth the investment for all your cool projects!

Safety Tips When Using a Metal Lathe

Essential safety practices to follow. Personal protective equipment (PPE) recommendations.Using a metal lathe can be fun but also dangerous. Keep safety first! Always wear personal protective equipment (PPE). This includes:

- Safety goggles to protect your eyes.

- Hearing protection for loud noises.

- Dust mask to breathe clean air.

- Gloves to keep your hands safe.

Follow these tips:

- Keep your workspace clean.

- Don’t wear loose clothing.

- Always check tools before use.

Have fun and stay safe while creating amazing things!

What are personal protective equipment recommendations for using a lathe?

When using a lathe, wear:

Safety goggles, hearing protection, a dust mask, and gloves. These simple items help keep you safe.

Getting Started with Your Lathe Floor Mount Metal Lathe

Initial setup and installation guidelines. Basic operations and techniques for beginners.Setting up your lathe floor mount metal lathe is simple! Here are quick steps for an easy start:

- Find a stable surface for your lathe. It needs to be level and strong.

- Secure all parts tightly. Double-check everything to avoid accidents.

- Start with simple tasks. Practice cutting straight lines using the tool. Be gentle.

- Keep your work area clean. Safety comes first!

Remember, patience is key. It takes time to get comfortable. Enjoy the process!

What should beginners know about lathe operations?

Beginners should focus on safety, practices, and basic techniques. Use both hands to guide the tools. Keep your fingers away from cutting parts. Always wear safety goggles for protection.

Conclusion

In summary, a floor mount metal lathe is a powerful tool for shaping metal. It offers stability and precision for various projects. You can create parts for machines or crafts easily. If you’re interested in metalworking, consider getting one or reading more about how they work. Start exploring the world of lathes today and unlock your creativity!FAQs

What Are The Key Features To Look For When Selecting A Floor Mount Metal Lathe For A Workshop?When choosing a floor mount metal lathe, you should look for a few important things. First, check the size. It should fit in your workshop space. Next, see how much weight it can handle. This tells you how strong it is. Finally, make sure it has easy controls so you can use it easily. These features will help you work safely and effectively.

How Does The Size And Weight Of A Floor Mount Metal Lathe Affect Its Stability And Performance?A floor mount metal lathe is a big tool used for shaping metal. The larger and heavier it is, the more stable it becomes. This means it won’t move or shake much while you work. A stable lathe lets you make smoother and more accurate pieces. So, size and weight help it perform better!

What Types Of Materials Can A Floor Mount Metal Lathe Effectively Work With, And What Considerations Are Needed For Each?A floor mount metal lathe can work with materials like metal, wood, and plastic. For metal, you should pick the right type, like aluminum or steel, as they are strong. When using wood, make sure it’s dry and clean to get a smooth finish. For plastic, choose the right kind, so it doesn’t melt or chip while you work. Always remember to wear safety gear and be careful around sharp tools!

What Are The Differences Between Manual And Cnc Floor Mount Metal Lathes In Terms Of Usability And Precision?Manual floor mount metal lathes need you to control the machine yourself. You turn the dials and move parts by hand. This requires practice and can be harder to use. CNC stands for Computer Numerical Control. CNC lathes are easier because they follow instructions from a computer, making them more precise and faster. So, CNC lathes can create more accurate shapes than manual ones.

What Are Some Essential Maintenance Tips For Ensuring The Longevity And Efficient Operation Of A Floor Mount Metal Lathe?To keep your metal lathe in great shape, clean it regularly. Wipe off dust and metal shavings after each use. You should also oil the moving parts so they don’t get rusty. Check the belts and gears for wear, and replace them if needed. Finally, make sure everything is tight and secure to avoid accidents.