Have you ever wondered how metal parts are made? One of the best tools for the job is a lathe. Imagine shaping metal into perfect pieces, just like a sculptor. A floor mount metal lathe does just that, standing tall and sturdy in a workshop.

These machines can create everything from tiny screws to large machine parts. With the right CAD design, you can visualize your projects before you even start. This saves time and helps you make better choices.

Did you know that some lathes are so precise that they can create parts to a tolerance of just a few thousandths of an inch? That’s like cutting a piece of paper into tiny strips! This article will dive into the world of lathe floor mount metal lathes and explore their amazing capabilities.

Lathe Floor Mount Metal Lathe Cad Design: A Comprehensive Guide

Lathe Floor Mount Metal Lathe CAD Design

A lathe is a powerful tool for shaping metal. Floor-mounted metal lathes save space and provide stability during use. CAD design makes creating lathe parts easier and more precise. Imagine designing a custom part on your computer and watching it come to life with a lathe! This exciting combination of technology and craftsmanship helps both hobbyists and professionals make intricate designs efficiently. Learning about lathe CAD design opens the door to endless possibilities in metalworking!Understanding Lathe Floor Mount Metal Lathes

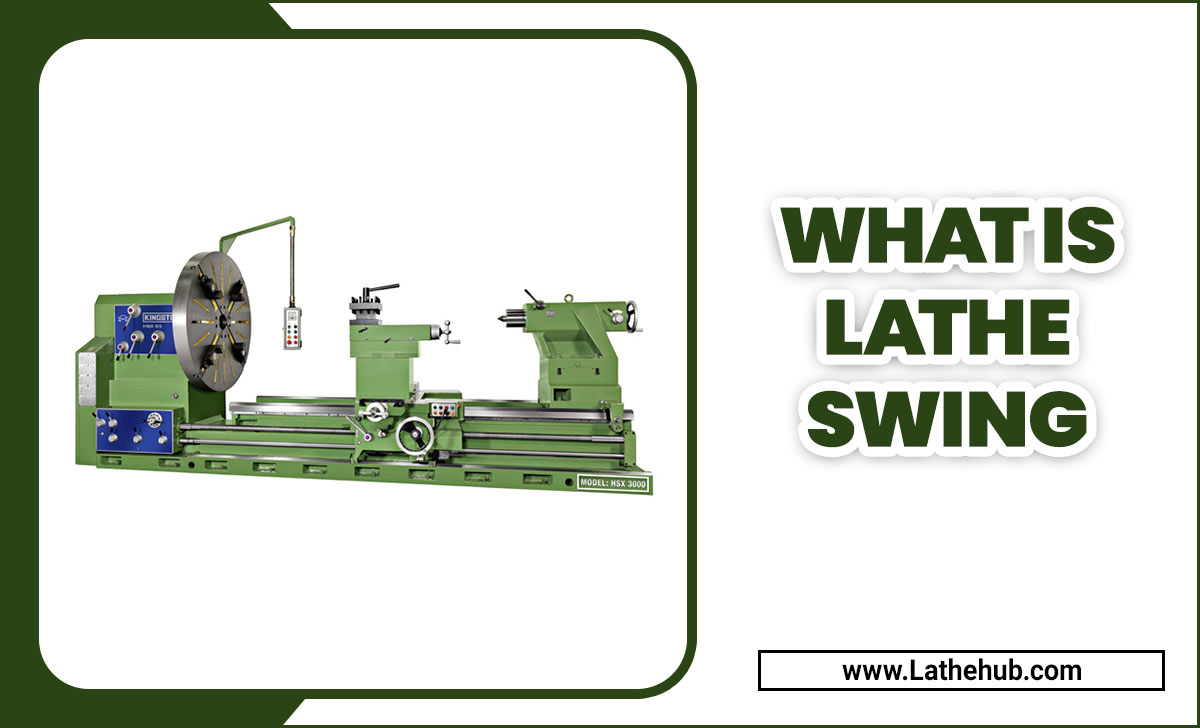

Definition and components of a floor mount metal lathe. Key advantages of using floor mount lathes in metalworking.A floor mount metal lathe is a powerful machine used in metalworking. It shapes metal by spinning it against sharp tools. Key parts of this lathe include the bed, headstock, tailstock, and carriage. Each part plays a role in helping the lathe work correctly.

- Stability: Floor mount lathes stay in place while working.

- Space-saving: They fit well in small workshops.

- Precision: They produce accurate parts every time.

Using a floor mount metal lathe makes tasks easier and more efficient!

What are the benefits of using a floor mount metal lathe?

Benefits include ease of use, high accuracy, and better support for heavy workpieces. They also free up workspace and improve safety in workshops.

Importance of CAD Design in Metalworking

Role of CAD in improving precision and efficiency. Common CAD software used for designing metal lathes.CAD design is very important in metalworking. It helps to create parts with high precision and boosts efficiency. When using CAD software, machines can make fewer mistakes. Some common CAD programs used for designing metal lathes include:

- AutoCAD

- SolidWorks

- Fusion 360

These tools make it easier to see how parts fit together before actual work begins. This saves time and materials. In fact, using CAD can increase productivity by up to 30%!

How does CAD improve metalworking?

CAD helps designers make accurate plans. This results in better parts and machines. It also lets users spot problems early. Using CAD can lead to fewer errors and faster production times.

Step-by-Step Process for Creating a CAD Design for a Floor Mount Metal Lathe

Initial planning and specification gathering. Choosing the right CAD software and tools.To create a solid CAD design for a floor mount metal lathe, start with careful planning. Gather all necessary specifications. Think about size, materials, and features you want. Next, choose the right CAD software. Some popular options are:

- AutoCAD

- Fusion 360

- SolidWorks

Each program has unique tools. Pick one that fits your needs and skill level. These early steps will help you design effectively.

What should I consider when planning my CAD design?

Focus on specifications, desired features, and the right CAD software for your skill level.

Key Features to Include in Your Design

Essential components: bed, tailstock, and headstock. Designing for safety and ease of use.Creating a clever design for your metal lathe requires some key features. First, the bed is essential; it’s the sturdy foundation that keeps everything in place, like a rock you can rely on! Next up is the tailstock, which helps support tools and ensures smooth work. Don’t forget about the headstock, where most action happens—it’s the captain of the ship!

Safety is also a big deal. Your design should have easy-to-reach controls and clear labels. Nobody wants to play hide-and-seek with the emergency stop button! Plus, make sure everything is comfortable to use. A lathe should feel like a cozy chair, not a prickly porcupine!

| Component | Function |

|---|---|

| Bed | Foundation for stability |

| Tailstock | Supports tools for accuracy |

| Headstock | Controls spindle rotation |

With these features, your lathe design can be safe, fun, and super effective. Remember, good design is like a well-cooked meal; it should be satisfying and easy to digest!

Best Practices for Floor Mount Metal Lathe CAD Design

Tips for optimization and scaling of designs. Common pitfalls to avoid during the design process.Designing a floor mount metal lathe in CAD can be fun and challenging. To make the best design, focus on these tips:

- Start with simple shapes. This helps in creating a clear design.

- Check dimensions carefully. Accurate measurements are important!

- Plan for future scaling. Think about how your design can change later.

Be aware of common mistakes. Avoid:

- Ignoring material thickness. It can affect your lathe’s strength.

- Overcomplicating the design. Keep it simple for easier building.

- Forgetting about machine limitations. Stay within the machine’s capabilities.

What are the main tips for lathe design?

Start with clear dimensions and consider future changes to your design to avoid errors.

Case Studies: Successful CAD Designs of Floor Mount Metal Lathes

Analysis of popular floor mount lathe designs. Lessons learned from existing designs.Many designs of floor mount metal lathes have shown great success. Each design teaches us something valuable. Popular styles focus on stability and ease of use. These lessons help improve future tools. Here are some important points:

- Efficiency: Easy controls make work faster.

- Durability: Strong materials last longer.

- Precision: Better alignment leads to sharper cuts.

Analyzing these designs can boost understanding. By learning from others, we can build even better machines.

What can we learn from successful designs of floor mount metal lathes?

We learn that focusing on quality and user feedback leads to better tools. A fine design meets needs and increases productivity.

Future Trends in Lathe Design and CAD Technology

Emerging technologies that influence CAD design in metal lathes. Predictions for the future of floor mount metal lathes in machining.New technologies are shaking up CAD design for metal lathes in exciting ways. Imagine using smart software that suggests improvements while you work—it’s like having a helpful robot buddy! Predictions show that floor mount metal lathes will become more user-friendly and precise. They might even come with features like real-time monitoring and automated adjustments. This means less guesswork and more shiny metal creations! Take a look at the chart below for a peek into future trends.

| Emerging Technology | Impact on Design |

|---|---|

| Smart Algorithms | Improved efficiency in design |

| 3D Printing | Faster prototyping for lathes |

| IoT Integration | Real-time performance data |

Resources and Tools for Metal Lathe CAD Design

Recommended CAD software and plugins. Online forums and communities for CAD designers in metalworking.For a successful metal lathe CAD design, start with the right software. Here are a few popular choices:

- AutoCAD – Known for its versatility and tools.

- Fusion 360 – Fantastic for collaboration and cloud access.

- SolidWorks – Great for 3D modeling.

Plugins can enhance these programs, making them even better. Check out online forums like Reddit or CAD forums for tips and support. Joining a community helps you learn from others. Fellow designers can offer advice and share their experiences. This support can really boost your projects.

What are useful online resources for CAD designers?

Online forums like CADTutor and the Autodesk community are valuable. They provide tips, troubleshooting help, and new ideas.

Conclusion

In summary, a lathe floor mount metal lathe is essential for precision work. CAD design helps you visualize your project before starting. Explore basics of machining and learn how to use CAD tools. By practicing these skills, you can create amazing designs. Keep experimenting and reading more to improve your projects!FAQs

What Are The Key Design Considerations For Creating A Cad Model Of A Floor-Mounted Metal Lathe?When creating a CAD (Computer-Aided Design) model of a floor-mounted metal lathe, we need to think about a few important things. First, we should make sure our model shows the right size and shape of the lathe. Next, we need to include details like the moving parts and how they fit together. It’s also important to think about how the lathe will be used and if it needs any extra safety features. Finally, we should check that the model can be easily understood by others.

How Can Cad Software Be Utilized To Optimize The Layout Of Components In A Lathe Design For Improved Accessibility And Operation?You can use CAD software, which stands for Computer-Aided Design, to plan where each part of the lathe goes. It helps you see where everything should be placed for easy access. You can move parts around easily and find the best spots. This way, using the lathe becomes safer and quicker. Plus, you can fix problems before building the machine!

What Materials Are Typically Recommended For A Floor Mount Metal Lathe, And How Can This Be Represented In Cad Designs?For a floor mount metal lathe, we usually use strong materials like steel and cast iron. These materials help the lathe be heavy and stable, which is important for accuracy. In CAD (Computer-Aided Design) software, you can show these materials by choosing their textures and colors. This makes the design look real and helps us see how the lathe will look and work.

How Do You Ensure That The Cad Design Of A Floor-Mounted Metal Lathe Complies With Safety Standards And Regulations?To make sure our CAD design for the lathe is safe, we check safety rules first. We look at guidelines from groups like OSHA, which is the Occupational Safety and Health Administration. We also read the lathe’s manual for safety tips. Then, we add safety features like guards and emergency stops. Finally, we ask experts to review our design before building it.

What Features Should Be Included In The Cad Design To Facilitate Maintenance And Repair Of A Floor Mount Metal Lathe?To make a floor mount metal lathe easy to fix, we should design it with features that help. First, include removable panels. This way, you can get to the inside parts easily. Second, add labels on the parts, so you know what everything does. Third, make sure the screws and bolts are easy to reach. Finally, design it with good lighting spots to help you see better while working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Design Considerations For Creating A Cad Model Of A Floor-Mounted Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When creating a CAD (Computer-Aided Design) model of a floor-mounted metal lathe, we need to think about a few important things. First, we should make sure our model shows the right size and shape of the lathe. Next, we need to include details like the moving parts and how they fit together. It’s also important to think about how the lathe will be used and if it needs any extra safety features. Finally, we should check that the model can be easily understood by others.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Optimize The Layout Of Components In A Lathe Design For Improved Accessibility And Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software, which stands for Computer-Aided Design, to plan where each part of the lathe goes. It helps you see where everything should be placed for easy access. You can move parts around easily and find the best spots. This way, using the lathe becomes safer and quicker. Plus, you can fix problems before building the machine!”}},{“@type”: “Question”,”name”: “What Materials Are Typically Recommended For A Floor Mount Metal Lathe, And How Can This Be Represented In Cad Designs? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a floor mount metal lathe, we usually use strong materials like steel and cast iron. These materials help the lathe be heavy and stable, which is important for accuracy. In CAD (Computer-Aided Design) software, you can show these materials by choosing their textures and colors. This makes the design look real and helps us see how the lathe will look and work.”}},{“@type”: “Question”,”name”: “How Do You Ensure That The Cad Design Of A Floor-Mounted Metal Lathe Complies With Safety Standards And Regulations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure our CAD design for the lathe is safe, we check safety rules first. We look at guidelines from groups like OSHA, which is the Occupational Safety and Health Administration. We also read the lathe’s manual for safety tips. Then, we add safety features like guards and emergency stops. Finally, we ask experts to review our design before building it.”}},{“@type”: “Question”,”name”: “What Features Should Be Included In The Cad Design To Facilitate Maintenance And Repair Of A Floor Mount Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a floor mount metal lathe easy to fix, we should design it with features that help. First, include removable panels. This way, you can get to the inside parts easily. Second, add labels on the parts, so you know what everything does. Third, make sure the screws and bolts are easy to reach. Finally, design it with good lighting spots to help you see better while working.”}}]}