Have you ever wondered how a simple piece of metal can become a beautiful part of a machine? The magic often lies in a tool called a lathe. A lathe helps shape metal into different forms. But to use a lathe effectively, you need a good controller.

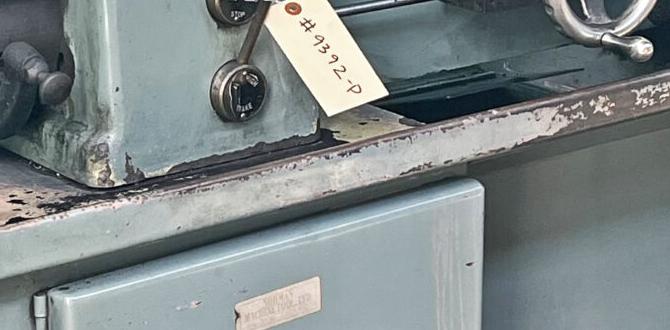

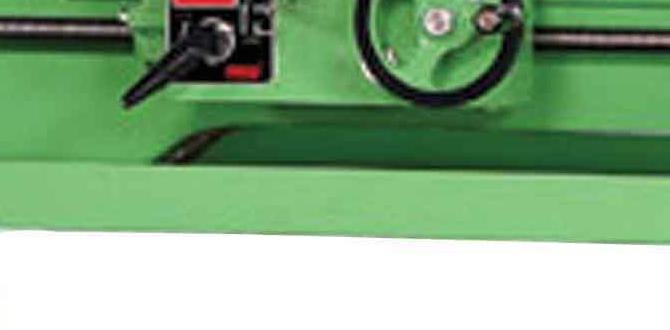

Meet the floor mount metal lathe controller. This tool not only controls the speed but also the precision of your lathe. Imagine making a perfect cut on a piece of metal with just the right speed! It makes your work easier and more precise.

Many people might not realize how important this tool is. A floor mount metal lathe controller can help both beginners and experts. It can take your projects from rough ideas to polished creations. Isn’t it fascinating how technology can transform your work? Let’s dive deeper into what makes this controller so special!

Lathe Floor Mount Metal Lathe Controller: An Essential Guide

Understanding Lathe Floor Mount Metal Lathe Controller

Want to take your metalworking to the next level? The lathe floor mount metal lathe controller offers precision and flexibility. This device controls the speed and movement of your lathe with ease. Did you know it can adapt to different materials? Imagine crafting detailed parts quickly and accurately. Enjoy features like user-friendly interfaces and programmable settings. With this controller, you’ll make clean cuts, improving your projects significantly. Dive into a world of creativity and precision today!Understanding Lathe Controllers

Definition and purpose of lathe controllers. Key components of a lathe controller system.A lathe controller is a device that helps run a lathe machine. Its main job is to tell the machine how to cut materials like wood or metal. This makes sure the shapes are just right. The key parts of a lathe controller system include:

- Power Supply: Provides energy to the machine.

- Control Panel: Where users set the machine’s functions.

- Motor Drives: Control the speed of the cutting tool.

- Feedback Systems: Ensure the machine stays on track while working.

Using these parts together makes tasks easier and more precise.

What does a lathe controller do?

A lathe controller helps a lathe machine cut materials. It gives exact instructions for shaping items. This makes the process quicker and helps prevent mistakes.

Benefits of Floor Mount Metal Lathe Controllers

Advantages of floormounted designs. Space efficiency and stability considerations.Floor-mounted metal lathe controllers offer many benefits. They are space-efficient and provide stability. This design keeps machines secure while using them. Stability helps prevent errors and accidents.

- Less floor space used, allowing more room for other tools.

- Improved safety due to a strong base.

- Easy access to controls for smooth operation.

What are the benefits of a floor mounted metal lathe controller?

Floor-mounted controllers save space while providing strong support. They ensure machines remain steady and easy to reach. This setup improves safety and helps users work more efficiently.

Key Features to Look For

Essential features for optimal performance (speed control, user interface). Additional features that enhance usability.Choosing the right lathe controller can be tricky! Speed control is vital for achieving the perfect cuts. Look for models that let you adjust speed easily, like turning a dial on the radio. Don’t forget about the user interface. It should be clear and friendly, kind of like your best buddy guiding you through a game. Additional features, like built-in safety locks or emergency stops, are lifesavers—just like a superhero in the workshop! Check out these must-have features:

| Feature | Description |

|---|---|

| Speed Control | Allows precise adjustments for different materials. |

| User Interface | Simple and clear controls for easy operation. |

| Safety Features | Emergency stops and locks for protection. |

Installation Guide for Floor Mount Metal Lathe Controllers

Stepbystep installation process. Required tools and safety precautions.Installing a floor mount metal lathe controller may seem tricky, but with the right steps, it’s easy! Start by gathering your tools. You will need a screwdriver, a wrench, and safety goggles.

Follow these steps for a smooth installation:

- Read the instruction manual carefully.

- Make sure the area is clean and dry.

- Secure the lathe controller to the floor using bolts.

- Connect all wires according to the manual connections diagram.

- Double-check your work before powering it on.

Your safety is important! Always wear safety goggles to protect your eyes and ensure you handle tools carefully. You can do this!

What tools do I need for installation?

For installation, you will need a screwdriver, wrench, and safety goggles to stay safe during the process.

Maintenance Tips for Longevity

Routine maintenance practices for controllers. Troubleshooting common issues.Keeping your lathe controller happy is key to its long life. First, clean it regularly to remove dust and debris. Use a soft cloth—no need for a wrestling match with a scrubbing brush! Test the connections too. If anything is loose, it’s like a dance party with a partner who won’t hold on. Check for error messages; they are your controller’s way of saying, “Help me!” Here’s a quick troubleshooting table:

| Issue | Solution |

|---|---|

| Controller won’t turn on | Check the power source and connections. |

| Unusual noise | Inspect for loose parts or debris. |

| Error message | Refer to the manual or contact support. |

Follow these tips, and your metal lathe controller will thank you by lasting longer. Who knew machinery could be so needy? Treat it right, and it will work like a charm!

Cost Considerations and Budgeting

Price range of different metal lathe controllers. Factors influencing the cost of controllers.Buying a metal lathe controller can feel like shopping for a new pet. Do you want a puppy or a giraffe? Prices can vary widely. Most controllers range from $200 to $2,000 depending on features. Budget carefully! Factors like brand, size, and special functions impact the cost. It’s like choosing between a bicycle and a sports car! Be sure to see what suits your needs, just like picking the right snack for movie night.

| Controller Type | Price Range |

|---|---|

| Entry-level | $200 – $500 |

| Mid-range | $500 – $1,200 |

| High-end | $1,200 – $2,000 |

Comparative Analysis of Metal Lathe Controllers

Sidebyside comparison of popular models. Pros and cons of each model for informed decisionmaking.Choosing the right controller is key for your metal lathe. Let’s look at a few popular models side by side. Each model has its strengths and weaknesses.

- Model A: Easy to use and very accurate. But it can be pricey.

- Model B: Affordable with good features. However, it lacks some advanced options.

- Model C: Offers great customization. Unfortunately, setup can be tricky.

By weighing these pros and cons, you can make an informed choice. Remember, the best model depends on your needs!

What are the common features of metal lathe controllers?

Common features include speed control, precision settings, and user-friendly interfaces.

Key features often found are:

- Programmable settings

- Emergency stop buttons

- Real-time monitoring

Real-World Applications of Lathe Controllers

Industries that utilize floor mount metal lathe controllers. Case studies showcasing the effectiveness of various controllers.Many industries love using floor mount metal lathe controllers because they make work easier and more precise. For example, the automotive industry shapes parts with amazing accuracy. In a bakery, the controller can even help bake a perfectly round cake. Imagine a lathe spinning faster than a hamster on a wheel!

| Industry | Application | Case Study |

|---|---|---|

| Automotive | Shaping engine parts | Precision leads to safer cars. |

| Bakery | Creating perfectly round pastries | Consistent shapes make happy customers. |

With different controllers available, companies can choose what suits them best. A well-known quote says, “Precision is key!” This really sums it up. In short, these machines save time and improve quality. And who doesn’t want that?

Future Trends in Lathe Control Technology

Innovations and advancements in controller technology. Predictions for the future of lathe controllers in manufacturing.New technology is changing lathe controllers. Smart features will make them easier to use. So, what’s on the horizon? Here are some ideas:

- Improved software that helps with automation.

- More sensors for better monitoring and control.

- Integration with AI for smart adjustments.

In the future, lathe controllers will be faster and more reliable. Manufacturers will save time and reduce errors. Exciting changes are coming that will shift how we think about making things!

What are the future trends in lathe control technology?

The future trends include smart features, improved automation, and AI integration. These changes will enhance performance and efficiency in manufacturing.

Conclusion

In conclusion, a lathe floor mount metal lathe controller helps you operate your lathe more easily and accurately. This controller offers better control over your projects, making it simpler to shape metal. If you’re interested in machining, consider researching different models or trying one out. With the right controller, you can enhance your skills and create amazing projects!FAQs

What Are The Key Features To Consider When Selecting A Controller For A Floor Mount Metal Lathe?When choosing a controller for a floor mount metal lathe, you should look for a few important things. First, check the power rating. This tells you how strong the controller is. Next, consider the ease of use. You want buttons and screens that are simple to understand. Lastly, it’s good if the controller has safety features to keep you safe while you work.

How Does The Integration Of A Digital Controller Enhance The Functionality Of A Traditional Lathe?A digital controller helps a traditional lathe work better. It makes the lathe easier to use and more accurate. You can program it to cut shapes perfectly. This means we can create more complicated designs. Plus, it can save time and reduce mistakes.

What Types Of Feedback Systems Are Commonly Used In Lathe Controllers To Ensure Precision Machining?Lathe controllers use a few types of feedback systems to make sure they work precisely. One common system is called a position encoder. It tells the machine where the tool is at all times. Another system is the speed sensor, which helps control how fast the lathe spins. Together, these systems help make sure everything is cut perfectly.

Can You Explain The Role Of Programmable Logic Controllers (Plcs) In The Operation Of A Floor Mount Metal Lathe?Programmable Logic Controllers, or PLCs, are like smart helpers for machines. In a floor mount metal lathe, they control how the machine works. You can tell the PLC what to do using a computer. It helps the lathe make precise cuts in metal, ensuring everything is just right. This means better work and less waste!

What Maintenance Practices Are Recommended For Keeping A Lathe Controller In Optimal Working Condition?To keep a lathe controller working well, you should regularly clean it. Dust and dirt can cause problems, so use a dry cloth to wipe it. Check the connections to make sure they are tight and not damaged. Also, update the software if necessary. Finally, make sure to keep the area around the lathe tidy and safe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Selecting A Controller For A Floor Mount Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a controller for a floor mount metal lathe, you should look for a few important things. First, check the power rating. This tells you how strong the controller is. Next, consider the ease of use. You want buttons and screens that are simple to understand. Lastly, it’s good if the controller has safety features to keep you safe while you work.”}},{“@type”: “Question”,”name”: “How Does The Integration Of A Digital Controller Enhance The Functionality Of A Traditional Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital controller helps a traditional lathe work better. It makes the lathe easier to use and more accurate. You can program it to cut shapes perfectly. This means we can create more complicated designs. Plus, it can save time and reduce mistakes.”}},{“@type”: “Question”,”name”: “What Types Of Feedback Systems Are Commonly Used In Lathe Controllers To Ensure Precision Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe controllers use a few types of feedback systems to make sure they work precisely. One common system is called a position encoder. It tells the machine where the tool is at all times. Another system is the speed sensor, which helps control how fast the lathe spins. Together, these systems help make sure everything is cut perfectly.”}},{“@type”: “Question”,”name”: “Can You Explain The Role Of Programmable Logic Controllers (Plcs) In The Operation Of A Floor Mount Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Programmable Logic Controllers, or PLCs, are like smart helpers for machines. In a floor mount metal lathe, they control how the machine works. You can tell the PLC what to do using a computer. It helps the lathe make precise cuts in metal, ensuring everything is just right. This means better work and less waste!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended For Keeping A Lathe Controller In Optimal Working Condition? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a lathe controller working well, you should regularly clean it. Dust and dirt can cause problems, so use a dry cloth to wipe it. Check the connections to make sure they are tight and not damaged. Also, update the software if necessary. Finally, make sure to keep the area around the lathe tidy and safe.”}}]}