Have you ever wondered how metal parts get their perfect shapes? It’s often thanks to an amazing tool called a lathe. A lathe can spin metal while cutting it. This helps create precise and beautiful parts for many machines and tools.

One popular type is the floor mount metal lathe. This setup gives you stability and control. You can easily adjust the machine to cut exactly what you need. But, like all machines, it has many parts that work together.

Did you know that each part of a lathe plays a special role? From the bed that holds everything in place to the tailstock that helps you align, every piece is important. Understanding these parts helps you use the lathe better. It also makes it easier to fix or upgrade your machine.

So, what are the key components of a floor mount metal lathe? Why do they matter? Get ready to dive into the fascinating world of lathe parts and discover how they come together to create magic in metalworking.

Lathe Floor Mount Metal Lathe Parts: Essential Components Explained

Lathe Floor Mount Metal Lathe Parts

Discover essential parts of floor mount metal lathes that keep your projects on track. These machines help shape metal with precision. Key components include the bed, tailstock, and carriage. Each part plays a unique role in turning and shaping materials. Did you know that a robust lathe can last for decades with proper maintenance? Understanding these parts empowers users to get the most from their tools. Dive into the world of lathes and unlock your creative potential!Main Parts of a Floor Mount Metal Lathe

Description of key components: bed, carriage, tailstock, and headstock. Material types and manufacturing techniques for durability.A floor mount metal lathe has several key parts that work together. Each piece is important for making smooth and accurate cuts. The main components include:

- Bed: It supports the lathe and holds everything in place.

- Carriage: This moves the cutting tool along the bed.

- Tailstock: It helps hold the workpiece steady.

- Headstock: This contains the motor and drives the spinning process.

Manufacturers usually use strong materials like cast iron or steel. This makes each part last longer and resist damage. With proper care, a lathe can work well for many years.

Why is the bed important in a lathe?

The bed is the base of the lathe. It ensures everything is stable. A good bed helps to keep the cuts smooth and accurate.

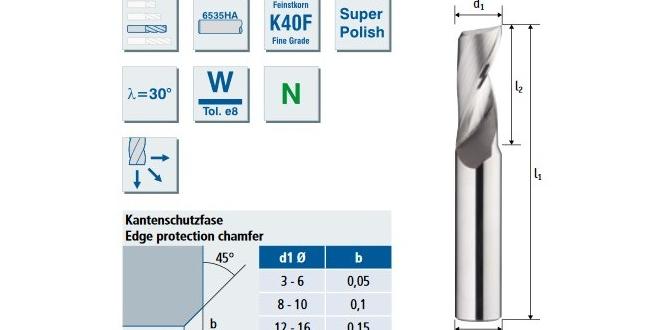

Types of Metal Lathe Parts

Different categories: OEM vs aftermarket parts. Pros and cons of each type.Metal lathe parts come in two main types: OEM and aftermarket. OEM stands for Original Equipment Manufacturer. These parts come right from the maker of the lathe. They often fit better and work like new. However, they are usually more expensive.

Aftermarket parts are made by other companies. They can be cheaper and sometimes offer new features. But, they might not fit perfectly or last as long.

- OEM Parts: High quality, better fit, but more expensive.

- Aftermarket Parts: Affordable and varied, but may compromise on quality.

What should I consider when choosing metal lathe parts?

Think about cost and quality. Check if the part fits your lathe model. It is also good to read reviews.

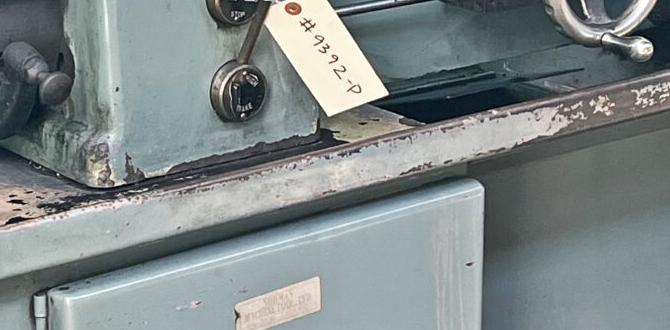

Maintaining Your Lathe Parts

Routine maintenance tips for longevity. Signs of wear and when to replace components.Keeping your lathe parts in shape is like giving them a spa day. Regular checks are key! Look for signs like strange noises or rust. If your lathe starts sounding like a dinosaur, it might be time for some TLC—or replacement parts! Check this table for common wear signs:

| Component | Signs of Wear | Replacement Needed? |

|---|---|---|

| Lathe Bed | Scratches or grooves | Before it gets too deep! |

| Tool Post | Loosening or wobbling | Yes, time for a new one! |

| Chuck | Cracks or poor grip | Absolutely! |

For longevity, clean and lubricate your lathe regularly, like feeding a pet. Happy lathe, happy crafter!

Upgrading Lathe Parts

Popular upgrades for improved performance. How to choose compatible upgrades based on your lathe model.Upgrading your lathe can make it work better and faster. Popular upgrades include new motors, tool rests, and better heads. These can help you achieve smoother cuts and more precise work.

When choosing upgrades, check your lathe model. Not all parts fit every machine. Look for parts that are made for your specific model.

Here are some upgrades to consider:

- High-quality tool rests: They provide better support and control.

- Upgraded motors: More power can improve speed and accuracy.

- Advanced tailstocks: They allow for easier adjustments.

What are some common upgrades for a lathe?

Common upgrades for a lathe include stronger motors, adjustable tool rests, and better tailstock mechanisms. These improvements help users create cleaner and more accurate workpieces.

How to find compatible upgrades?

Look for parts that match your lathe’s specifications. Always refer to your model’s manual for the best options.

Finding Quality Suppliers for Lathe Parts

Tips on sourcing reliable suppliers and manufacturers. Importance of warranty and customer service.Finding the right suppliers for lathe parts is key to your project. Start by checking online reviews and asking for recommendations. Consider the reputation and experience of the suppliers. Look for companies that offer a good warranty and strong customer service. This ensures you get help if something goes wrong. Reliable suppliers can save you time and money.

What should I look for in a supplier?

Focus on trustworthy reviews and fast responses. Ask about their experience and warranty policies.

Key tips to remember:

- Check product quality.

- Read customer feedback.

- Look for fair prices.

Common Issues with Lathe Parts

Typical problems encountered and troubleshooting steps. How to identify faulty components early.Lathe parts can have a few common issues. Early signs of trouble include strange noises and uneven cuts. Regular checks can help you find problems before they grow. Look for worn gears or loose bolts. These can cause big delays. Here are some typical problems and their fixes:

- Worn bearings: Replace them for smooth operation.

- Loose belts: Tighten them to improve function.

- Dull tools: Sharpen or change tools for better cuts.

If you notice any of these signs, it’s important to act quickly. Fixing minor problems now can save time and money later.

What are some signs of faulty lathe parts?

Signs include odd noises, poor cuts, and vibrations. Regular checks help to catch them early.

Safety Considerations When Working with Lathe Parts

Essential safety practices for operators. Protective gear and workspace setup for maximum safety.Staying safe while working with lathe parts is key. Always wear protective gear, like goggles, gloves, and a mask. Think of it as armor for your body! A tidy workspace is also important—clutter can cause accidents. Ensure all tools are in their rightful places. Implementing a “no horseplay” rule keeps everyone focused. Remember, the only thing that should spin are those lathe parts, not you!

| Safety Gear | Description |

|---|---|

| Goggles | Protects your eyes from flying debris. |

| Gloves | Prevent cuts and scrapes. |

| Mask | Keeps dust and harmful particles out of your lungs. |

Conclusion

In conclusion, lathe floor mount metal lathe parts are crucial for smooth operation. Understanding these parts helps you complete projects efficiently. You can explore different types and find the right fit for your needs. We encourage you to read more about lathe maintenance and accessories to enhance your skills. Happy crafting and good luck with your metalworking!FAQs

What Are The Essential Components Of A Floor-Mount Metal Lathe And How Do They Function Together?A floor-mount metal lathe has several important parts. First, there’s the bed, which is a strong base that holds everything. The headstock is next; it spins the metal piece. The tailstock helps support the other end of the metal. Finally, the carriage moves tools to shape the metal as it spins. All these parts work together to cut and shape the metal into different forms.

How Do You Properly Maintain And Lubricate The Parts Of A Floor-Mounted Metal Lathe For Optimal Performance?To keep a floor-mounted metal lathe working well, you should clean it regularly. Use a soft cloth to wipe away dust and chips. You must check the oil levels and add lubricant to moving parts. Make sure to follow the instructions in the user manual for what type of oil to use. Regular maintenance helps your lathe run smoothly!

What Safety Precautions Should Be Taken When Operating A Floor-Mount Metal Lathe?When using a floor-mount metal lathe, always wear safety glasses to protect your eyes. Make sure your hair and loose clothing are tied back so they don’t get caught in the machine. Keep your work area clean and organized to avoid accidents. Follow instructions carefully, and never distract someone who is working. Finally, always check that tools are in good shape before you start.

How Can You Troubleshoot Common Issues With The Components Of A Floor-Mount Metal Lathe?To troubleshoot problems with a floor-mount metal lathe, first check the power supply. Make sure it’s plugged in and turned on. Next, look for loose parts or broken pieces. Tighten any bolts and replace damaged parts if needed. Finally, read the manual for extra tips on fixing specific issues.

What Are The Differences Between Various Brands And Models Of Floor-Mount Metal Lathe Parts, And How Do They Impact Machining Capabilities?Different brands and models of floor-mount metal lathes have unique parts that can change how they work. Some lathes have stronger motors, making them better for tough jobs. Others might have more tools or attachments, giving you more options for shaping metal. The size and material of the parts also matter. If parts are bigger or made of better metal, the lathe can perform better and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Of A Floor-Mount Metal Lathe And How Do They Function Together? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A floor-mount metal lathe has several important parts. First, there’s the bed, which is a strong base that holds everything. The headstock is next; it spins the metal piece. The tailstock helps support the other end of the metal. Finally, the carriage moves tools to shape the metal as it spins. All these parts work together to cut and shape the metal into different forms.”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Lubricate The Parts Of A Floor-Mounted Metal Lathe For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a floor-mounted metal lathe working well, you should clean it regularly. Use a soft cloth to wipe away dust and chips. You must check the oil levels and add lubricant to moving parts. Make sure to follow the instructions in the user manual for what type of oil to use. Regular maintenance helps your lathe run smoothly!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Floor-Mount Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a floor-mount metal lathe, always wear safety glasses to protect your eyes. Make sure your hair and loose clothing are tied back so they don’t get caught in the machine. Keep your work area clean and organized to avoid accidents. Follow instructions carefully, and never distract someone who is working. Finally, always check that tools are in good shape before you start.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues With The Components Of A Floor-Mount Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot problems with a floor-mount metal lathe, first check the power supply. Make sure it’s plugged in and turned on. Next, look for loose parts or broken pieces. Tighten any bolts and replace damaged parts if needed. Finally, read the manual for extra tips on fixing specific issues.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Various Brands And Models Of Floor-Mount Metal Lathe Parts, And How Do They Impact Machining Capabilities? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different brands and models of floor-mount metal lathes have unique parts that can change how they work. Some lathes have stronger motors, making them better for tough jobs. Others might have more tools or attachments, giving you more options for shaping metal. The size and material of the parts also matter. If parts are bigger or made of better metal, the lathe can perform better and last longer.”}}]}