Have you ever watched a metal lathe in action? It’s fascinating how this tool shapes metal into useful parts. One key component is the lathe floor mount metal lathe pulley. But what exactly does this pulley do?

Imagine a busy workshop filled with the sounds of machinery. A metal lathe spins smoothly, cutting metal with precision. The lathe floor mount metal lathe pulley controls the speed and direction of the lathe’s movement. Without it, the lathe would struggle to work properly.

Did you know that the right pulley can make your lathe run better and last longer? Choosing the right lathe floor mount metal lathe pulley can be the difference between a great project and a frustrating one.

If you’re curious about how these pulleys work and why they matter, you’re in the right place! Let’s dive deeper into the world of lathe floor mount metal lathe pulleys and discover their importance in metalworking.

Lathe Floor Mount Metal Lathe Pulley: A Comprehensive Guide

Lathe Floor Mount Metal Lathe Pulley

A lathe floor mount metal lathe pulley is an essential tool in workshops. It helps control the speed of the lathe, making it easier to shape metal. Did you know that different pulley sizes can affect the lathe’s performance? Choosing the right pulley size can enhance efficiency and lead to better results. Understanding how these pulleys work can save time and improve projects. Get ready to dive into the exciting world of metalworking!Understanding Lathe Floor Mount Metal Lathes

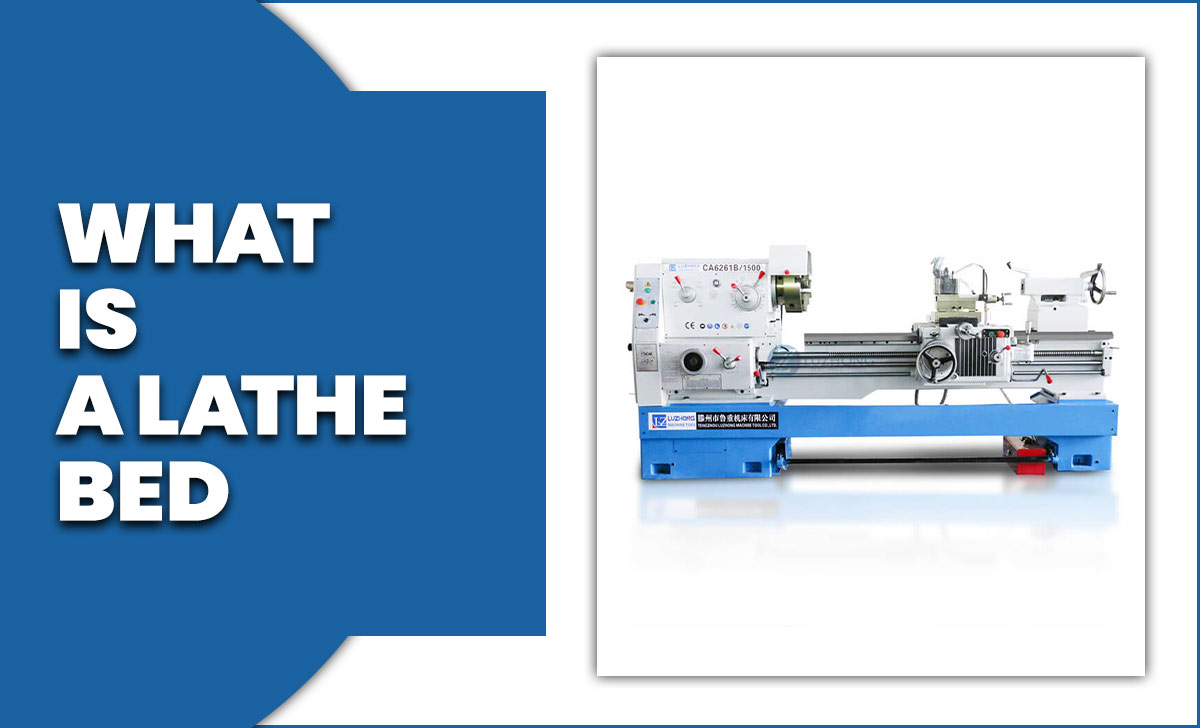

Definition and purpose of floor mount metal lathes. Key features differentiating them from other lathe types.A floor mount metal lathe is a machine that helps shape and cut metal. Think of it as a friendly giant that can turn a metal block into a perfect bottle opener! These lathes stand firmly on the floor, unlike other types that might dance around. One key feature is their stability, which keeps them from wobbling like a jelly on a hot day. They often have powerful motors and larger workspaces, making them a hit for serious metalworking.

| Feature | Floor Mount Lathe | Other Lathes |

|---|---|---|

| Stability | High | Variable |

| Workspace Size | Large | Small |

| Motor Power | Powerful | Less Powerful |

Benefits of Using a Pulley System in Metal Lathes

Improved torque and speed control. Enhanced durability and reduced maintenance needs.Using a pulley system in metal lathes brings some great benefits. First, it helps with improved torque and speed control. This means you can change how fast or slow the lathe runs easily, like flipping a switch on a video game controller! Second, these systems are known for their enhanced durability and less need for maintenance. That’s right—fewer visits to the repair shop! In fact, some studies show that machines with pulleys can last up to 20% longer. Plus, who wouldn’t want to spend less time fixing things?

| Benefit | Details |

|---|---|

| Torque Control | Easy adjustments for different tasks |

| Speed Control | Find the perfect speed for your project |

| Reduced Maintenance | Spend more time working, less time fixing |

| Durability | Longer tool lifespan—hooray! |

Types of Pulley Systems for Metal Lathes

Variable speed pulleys vs. fixed speed pulleys. Description of commonly used materials for pulleys.Pulleys are important in metal lathes. There are two main types: variable speed pulleys and fixed speed pulleys. Variable speed pulleys let you change the speed easily. They are great for different tasks. Fixed speed pulleys run at one speed. They are simpler and often cheaper. Common materials for pulleys include:

- Steel: Strong and durable.

- Aluminum: Lightweight and resistant to rust.

- Plastic: Cost-effective and although less strong, it works well in light-duty tasks.

Choosing the right pulley can make your work easier and your lathe more efficient.

What are the benefits of variable speed pulleys?

Variable speed pulleys adjust quickly, making machines versatile and useful for different projects.

What materials are best for pulley systems?

Steel and aluminum are best for strength. Plastic works for lighter tasks.

Installation Guide for Floor Mount Metal Lathe Pulley Systems

Stepbystep installation process. Common pitfalls to avoid during installation.Installing a floor mount metal lathe pulley can seem tricky, but it’s easy with a step-by-step guide. First, make sure you have all tools ready. Then follow these steps:

- Gather your tools: wrench, screws, and the pulley.

- Attach the pulley to the lathe base securely.

- Connect the motor and ensure everything is aligned.

- Test the system before finalizing the installation.

Be cautious of common mistakes. Ensure everything is tight to avoid any wobbling. Double-check the alignment to prevent damage over time.

What should I avoid during installation?

Avoid leaving loose screws. Make sure all parts fit together well. Check for any obstructions that might interfere with the pulley. This helps keep everything running smoothly.

Following these tips will set you up for success. Enjoy your new lathe pulley system!

Maintenance Tips for Pulley Systems in Metal Lathes

Recommended maintenance schedule. Signs that indicate when the pulley system needs servicing.To keep your lathe’s pulley system working well, follow a regular maintenance schedule. Check your pulleys every month for wear and tear. Pay attention to signs of trouble, such as strange noises, vibrations, or difficulty in operation. If you notice these issues, it might be time for servicing. This will keep everything running smoothly and safely.

What are the signs that indicate a need for servicing?

Some clear signs include:

- Noisy pulleys that sound different from normal.

- Vibrations during operation that feel off.

- Difficulty in switching speeds effectively.

Common Issues and Troubleshooting

Identifying signs of pulley system malfunction. Solutions for common problems faced by operators.To spot problems in the pulley system, look for unusual noises. If you hear squeaking or grinding, it’s time to inspect. Signs like slipping belts or uneven rotation also mean trouble. Common fixes include:

- Lubricating the bearings to reduce noise.

- Replacing worn belts for better grip.

- Adjusting tension to prevent slippage.

Regular check-ups will help keep everything running smoothly!

What are signs of pulley malfunction?

Look for strange noises or uneven spinning. **These signs mean the system might need help.**

Choosing the Right Lathe Floor Mount Metal Lathe Pulley

Factors to consider: size, material, and compatibility. Recommended brands and models in the market.Picking the right lathe floor mount metal lathe pulley isn’t too hard, but some things matter. First, think about the size. It should match your lathe. Next, check the material. Metal pulleys last longer and handle more weight than plastic. Lastly, ensure it works with your current machine. Some great brands to consider are:

- Grizzly

- Jet

- Shop Fox

These offer strong and reliable pulleys for different needs.

What should I consider when buying a lathe pulley?

Look at size, material, and compatibility. Each matters for performance and durability.

Case Studies: Successful Implementation of Pulley Systems

Example scenarios of businesses enhancing productivity with pulley systems. Lessons learned and best practices highlighted from the case studies.Pulley systems have truly helped many businesses work better and faster. For example, a toy factory used pulleys to lift heavy materials. This made their workers more efficient. They started making more toys every day. Here are some lessons they learned:

- Use strong materials for pulleys.

- Regular checks keep pulleys running smoothly.

- Train workers to handle pulleys safely.

These steps helped boost productivity and keep the workplace safe.

How do pulley systems improve productivity?

With pulleys, machines can lift heavy items easily. This reduces worker strain and speeds up tasks. Companies see more output in less time.

Conclusion

In summary, a lathe floor mount metal lathe pulley is essential for smooth and efficient machining. It helps control speed and torque, making your work easier. If you’re starting a project, consider investing in one. We recommend researching different models and reading user reviews. By doing this, you can find the best pulley for your needs and improve your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Pulleys:Sure! A floor mount metal lathe is a tool that helps us shape metal. It has special round parts called pulleys. These pulleys help turn the metal piece as we work on it. You can adjust the size of the pulleys to change how fast the metal spins. This makes it easier to create different shapes and sizes.

Sure! Please provide the question you’d like me to answer.

What Are The Key Functions Of Pulleys In A Floor-Mounted Metal Lathe System?Pulleys in a floor-mounted metal lathe help move the machine parts. They use ropes or belts to transfer power from the motor to the lathe. This makes the lathe spin and cut metal. Pulleys can also change the speed, so you can work on different projects. They make everything smoother and easier to control!

How Do You Determine The Appropriate Pulley Size For A Specific Lathe Application?To choose the right pulley size for your lathe, you need to think about a few things. First, check the speed you want your lathe to run. You also need to know the size of the motor that powers the lathe. Next, look at the sizes of the pulleys you already have. Finally, you can use a simple math formula to find the best pulley size that matches your needs.

What Materials Are Commonly Used For Manufacturing Pulleys In Metal Lathes, And Why?Pulleys in metal lathes are often made from steel, aluminum, and sometimes plastic. Steel is strong and lasts a long time. Aluminum is lighter and doesn’t rust easily. Plastic can be used for lighter jobs. We choose these materials because they are durable and work well for moving parts.

Can You Explain The Benefits Of Using A Variable Speed Pulley System In A Metal Lathe?A variable speed pulley system lets you change how fast the metal lathe spins. This is great because you can work with different types of metal. Sometimes you need to go slow for tricky cuts, and other times fast works better. It helps you make better shapes and smoother surfaces. Overall, it makes your work easier and more fun!

What Are The Common Issues That Can Arise With Lathe Pulleys, And How Can They Be Addressed?Lathe pulleys can have a few common problems. Sometimes, they can wobble or shake. This happens if they are not snug on the spindle. You can fix this by tightening them. Another issue is that the belt can wear out. If this happens, you should replace the belt to keep everything running smoothly.