Imagine standing next to a powerful machine that turns metal into precise shapes. This machine is a lathe, and it plays a key role in metalworking. Among the various components of a lathe, the **floor mount metal lathe saddle** stands out. But what exactly does the saddle do?

The saddle helps guide the cutting tool. It moves left and right, and up and down. This motion allows the lathe to shape metal pieces accurately. Have you ever wondered how artisans create complex metal parts? Often, it starts with a lathe and its essential components.

Fun fact: Did you know that lathes date back thousands of years? Ancient craftsmen used simple lathes to carve wood and stone. Today, the floor mount metal lathe saddle continues this tradition in a modern way. It makes metalworking easier and more efficient.

In this article, we will explore the importance of the lathe floor mount metal lathe saddle. You will learn how it works and why it matters in metalworking. Ready to dive into the world of lathes? Let’s get started!

Lathe Floor Mount Metal Lathe Saddle – Overview And Benefits

Lathe Floor Mount Metal Lathe Saddle

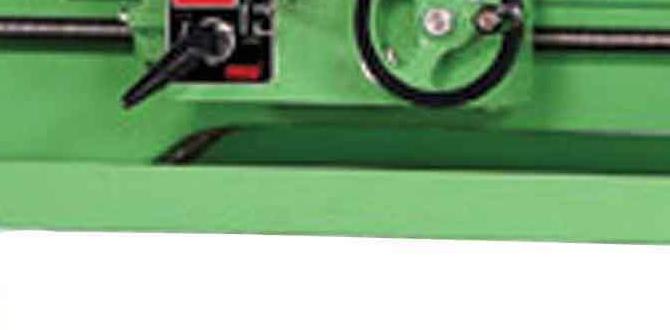

The lathe floor mount metal lathe saddle is a key component for precision machining. Designed to hold the cutting tool and move along the workpiece, it ensures smooth operations. Imagine crafting metal parts with exact shapes and sizes—just like in movies! Did you know that an adjustable saddle can greatly enhance your project’s accuracy? Understanding the saddle’s role can transform your metalworking projects from simple to exceptional. Dive in and explore how it can elevate your craftsmanship!What is a Metal Lathe Saddle?

Definition and purpose of a metal lathe saddle. Key features that distinguish quality saddles.A metal lathe saddle is an essential part of a lathe machine. It holds the cutting tool and moves it for precise shaping of metal pieces. Quality saddles help ensure smooth operation. They can make a big difference in a project’s success.

- Sturdy Material: Good quality saddles are made from strong metals.

- Precision Design: They need to fit perfectly to guide tools correctly.

- Smooth Motion: Look for features that allow easy movement.

What are the key benefits of using a metal lathe saddle?

The main benefits include better accuracy in shaping metal and increased durability. A sturdy saddle reduces wear and tear on tools, enhancing the overall efficiency of metalworking.

Importance of Choosing the Right Saddle

How the saddle impacts machining accuracy and stability. Effects of saddle material and construction on performance.Choosing the right saddle is like picking the perfect pair of shoes—size matters! The saddle impacts machining accuracy and stability a lot. If it wobbles, your projects turn out a bit like Picasso’s early work. Think about the materials; heavier saddle materials often ensure better stability. The right construction adds to performance, too. A well-made saddle can be the difference between smooth sailing and a bumpy ride in your workshop.

| Saddle Material | Performance |

|---|---|

| Cast Iron | Excellent stability and reduces vibrations. |

| Aluminum | Lightweight but may vibrate if not secured properly. |

| Steel | Strong and durable, offers good support for heavy tasks. |

Installation Guide for Floor Mount Metal Lathes

Stepbystep instructions for proper installation of the saddle. Tips for ensuring alignment and leveling.First, grab your saddle and lay it on the lathe bed. Make sure it’s snug like a burrito! Next, use bolts to secure the saddle. Tighten them evenly to avoid a lopsided situation – no one likes a wobbly lathe. For leveling, use a spirit level. If it’s not level, adjust the feet like a pro building a sandcastle.

| Step | Action |

|---|---|

| 1 | Place the saddle on the lathe bed. |

| 2 | Fasten bolts securely. |

| 3 | Check alignment with a spirit level. |

| 4 | Adjust feet if needed. |

Following these steps keeps your metal lathe happy, and in turn, you’ll be happy too! A well-setup lathe makes for great projects. Happy turning!

Maintenance Tips for Metal Lathe Saddles

Routine maintenance practices for optimizing saddle performance. Common issues and troubleshooting advice.Keeping your metal lathe saddle in tip-top shape is crucial for smooth operations. Start with routine cleaning to remove dust and debris. Regularly check the saddle for signs of wear. You don’t want it to look like it’s been through a war! If you notice unusual noises or stiffness, it’s time to troubleshoot. A simple adjustment may solve the issue faster than you can say “lathe!”

| Tip | Action |

|---|---|

| Cleaning | Wipe down after each use. |

| Check for Wear | Inspect monthly for damage. |

| Troubleshooting | Adjust settings if you hear funny sounds! |

Comparative Analysis of Popular Metal Lathe Saddles

Review of top brands and models in the market. Pros and cons of each option to help in decisionmaking.Different metal lathe saddles offer unique features. Here’s a brief look at some well-known brands and models:

- Brand A: Known for its strong build. Great for heavier projects. Cons: It can be heavy to move.

- Brand B: Lightweight and portable. It’s easy to use for beginners. Cons: Some parts feel less sturdy.

- Brand C: Offers precision and durability. Ideal for detailed work. Cons: It has a higher price.

This comparison helps you understand which option fits your needs best.

What is the best lathe saddle for beginners?

The best lathe saddle for beginners is one that is portable and easy to use. Look for models that have clear instructions. Brands like Brand B are often recommended for learning.

Upgrading Your Lathe Saddle

Indicators that it’s time to consider an upgrade. Benefits of modern saddles and potential enhancements.Upgrading your saddle can greatly improve your lathe. Look for signs like wear, rust, or difficulty in movement. A modern saddle offers benefits like better precision and easier adjustments. These upgrades can help create smoother projects.

- Increased accuracy in your work.

- More durable materials reduce wear.

- Easier installation for quick upgrades.

- Enhanced features for better performance.

Why Upgrade Your Lathe Saddle?

It is time for an upgrade if you notice uneven cuts or frequent adjustments. A new saddle can boost your work speed and precision. Modern saddles improve accuracy and save you time.

Safety Considerations When Using Metal Lathes

Best practices to ensure safe operation of the lathe. Essential personal protective equipment (PPE) for users.Using a metal lathe can be exciting, but safety comes first! Always keep the area clean and clutter-free. Think of it as a dance floor—no one likes stepping on toes! Essential personal protective equipment (PPE) includes safety goggles to protect those peepers and ear protection to keep your eardrums happy. Don’t forget those gloves to avoid any ‘hands-on’ accidents!

| Safety Gear | Purpose |

|---|---|

| Safety Goggles | Protect your eyes from flying debris. |

| Ear Protection | Guard your ears from loud noise. |

| Gloves | Keep your hands safe from sharp tools. |

Remember, safety is no accident! Always follow best practices, like keeping long hair tied back. Think of your metal lathe as a lion: majestic, yet it deserves respect!

Conclusion

In conclusion, a lathe floor mount metal lathe saddle is essential for stability and accuracy. It supports the lathe and helps produce precise parts. By understanding its features, you can improve your metalworking projects. We encourage you to explore more about lathe components and practices. Start experimenting in your workshop today, and see how it enhances your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Saddle:Sure! A lathe is a machine that helps us shape metal. The saddle is a part that holds and moves the metal piece. When we use a floor mount lathe, it stands on the ground. It’s like a strong table for our work. You can make lots of cool shapes with it!

Sure! Please provide the question you’d like me to answer.

What Are The Key Components Of A Lathe Saddle And How Do They Contribute To Its Overall Functionality?A lathe saddle has a few important parts. First, there’s the base, which holds everything steady. Next, we have the cross slide, which moves side to side. It helps us cut the material evenly. Finally, there’s the tool holder, where we place our cutting tools. Together, these parts help us shape and cut materials smoothly.

How Does The Design Of A Floor Mount Lathe Affect The Stability And Precision Of The Saddle During Machining Operations?The design of a floor mount lathe helps keep it steady while you work. A strong base makes sure the lathe doesn’t wobble. This means the saddle, which holds the tool, can move smoothly and accurately. When everything is stable, you can create better shapes and sizes in your projects.

What Materials Are Commonly Used In The Construction Of Lathe Saddles To Enhance Durability And Performance?Lathe saddles are often made from strong materials like cast iron and steel. These materials help them last longer and work better. We also use special coatings to protect them from rust. This means they stay in good shape, even after lots of use.

How Can Users Maintain And Troubleshoot Common Issues With The Saddle Of A Floor Mount Metal Lathe?To keep the saddle of a floor mount metal lathe working well, you should clean it regularly. Remove any dust or chips that build up. Make sure to check the oil levels and fill them if they are low. If the saddle sticks, look for anything blocking its path or add some oil. If you have a problem you can’t fix, ask someone with experience for help.

What Specific Adjustments Can Be Made To The Lathe Saddle To Improve Accuracy And Reduce Wear On Workpieces?To improve accuracy and reduce wear on workpieces, you can adjust the lathe saddle in a few ways. First, make sure it moves smoothly along the ways. You can clean and oil the parts to keep them working well. Second, check the alignment of the saddle to ensure it is straight. Finally, tighten loose screws but not too tight, so everything stays firm without getting stuck.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. The saddle is a part that holds and moves the metal piece. When we use a floor mount lathe, it stands on the ground. It’s like a strong table for our work. You can make lots of cool shapes with it!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Lathe Saddle And How Do They Contribute To Its Overall Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe saddle has a few important parts. First, there’s the base, which holds everything steady. Next, we have the cross slide, which moves side to side. It helps us cut the material evenly. Finally, there’s the tool holder, where we place our cutting tools. Together, these parts help us shape and cut materials smoothly.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Floor Mount Lathe Affect The Stability And Precision Of The Saddle During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a floor mount lathe helps keep it steady while you work. A strong base makes sure the lathe doesn’t wobble. This means the saddle, which holds the tool, can move smoothly and accurately. When everything is stable, you can create better shapes and sizes in your projects.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used In The Construction Of Lathe Saddles To Enhance Durability And Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe saddles are often made from strong materials like cast iron and steel. These materials help them last longer and work better. We also use special coatings to protect them from rust. This means they stay in good shape, even after lots of use.”}},{“@type”: “Question”,”name”: “How Can Users Maintain And Troubleshoot Common Issues With The Saddle Of A Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the saddle of a floor mount metal lathe working well, you should clean it regularly. Remove any dust or chips that build up. Make sure to check the oil levels and fill them if they are low. If the saddle sticks, look for anything blocking its path or add some oil. If you have a problem you can’t fix, ask someone with experience for help.”}},{“@type”: “Question”,”name”: “What Specific Adjustments Can Be Made To The Lathe Saddle To Improve Accuracy And Reduce Wear On Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To improve accuracy and reduce wear on workpieces, you can adjust the lathe saddle in a few ways. First, make sure it moves smoothly along the ways. You can clean and oil the parts to keep them working well. Second, check the alignment of the saddle to ensure it is straight. Finally, tighten loose screws but not too tight, so everything stays firm without getting stuck.”}}]}