Have you ever thought about how a simple lathe can transform your projects? Imagine being able to create beautiful metal parts right in your workshop. A floor mount metal lathe upgrade can make this dream a reality.

Many hobbyists start with basic tools. But as skills grow, so does the desire for better equipment. A metal lathe that sits on the floor is more stable and powerful. It’s designed for bigger tasks. This opens a new world of possibilities.

Did you know that some of the best machinists swear by their floor mount lathes? They say these machines help them work faster and smarter. Upgrading your lathe can make your work more enjoyable too! You might even surprise yourself with what you can create.

Are you ready to take your crafting to the next level? Let’s explore how a lathe floor mount metal lathe upgrade can help you unleash your creativity and skills.

Lathe Floor Mount Metal Lathe Upgrade: Enhance Your Workshop

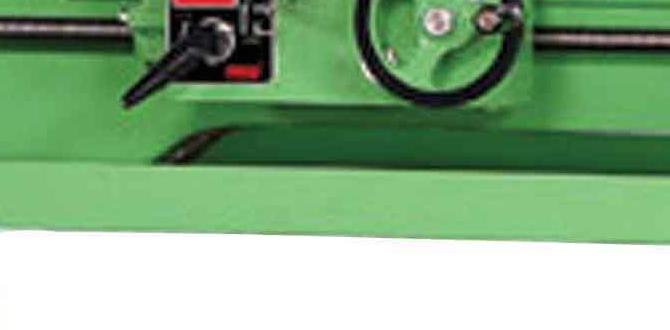

Lathe Floor Mount Metal Lathe Upgrade

Upgrading to a lathe floor mount metal lathe can boost your crafting game. Imagine turning metal with precision, making custom parts for your projects. These lathes are sturdy and offer greater stability, helping you create smoother finishes. You can easily tackle larger pieces, unlocking new possibilities in metalworking. A fun fact: with the right tools, your lathe can last a lifetime! Consider an upgrade to enhance your skills and equipment today.Understanding the Basics of Floor Mount Metal Lathes

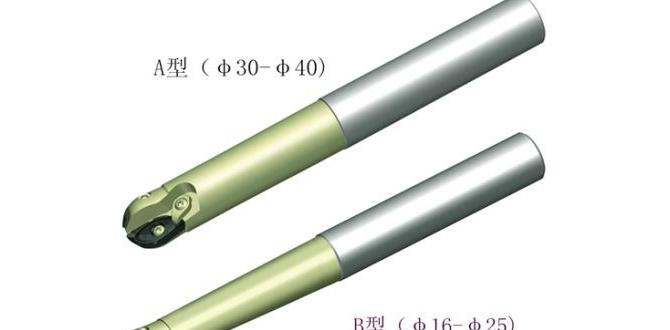

Definition and key features of floor mount metal lathes. Advantages compared to other types of lathes.Floor mount metal lathes are powerful machines used to shape metal. They are fixed to the floor, giving them stability for heavy projects. Key features include a strong frame, adjustable speeds, and a variety of tooling options. These lathes are great for precision and durability. Compared to other lathes, they offer:

- Better stability while cutting

- Higher accuracy for detailed work

- More power for larger projects

What are the benefits of floor mount metal lathes?

They provide high stability, allow for precise machining, and enable heavier items to be worked with ease. This means smoother cuts and better results in projects.

Key Upgrades for Enhanced Performance

Essential components to replace for improved accuracy. Benefits of upgrading your lathe’s motor and drive system.Upgrading your lathe can be as exciting as finding extra fries at the bottom of the bag! Replacing key parts will boost accuracy. For example, a new tailstock can help your projects go smoother. Upgrading the motor and drive system is like giving your lathe a shot of espresso. It makes everything faster and more reliable. This means less wobble and more wow! Here’s a quick table to show what you might consider changing:

| Component | Benefit |

|---|---|

| Tailstock | Improved accuracy |

| Motor | Faster operation |

| Drive System | Stable performance |

Small upgrades can make a huge difference, transforming your workbench into a craftsmanship wonderland!

Installation Process: Step-by-Step Guide

Tools required for a successful upgrade. Detailed instructions for upgrading different components.Upgrading your lathe can be a piece of cake if you have the right tools. You’ll need a wrench set, screwdriver, and perhaps a level—trust me, leveling is key! Once you’re suited up, follow these steps to upgrade each component like a pro. Picture this: swapping old parts for shiny new ones while your friends think you’re a wizard. Here’s a quick guide to keep everything on track:

| Component | Tools Needed | Instructions |

|---|---|---|

| Motor | Wrench, Screwdriver | Remove screws, swap motors, and tighten! |

| Tailstock | Level, Allen Wrench | Loosen bolts, adjust, and check level. |

| Bed | Wrench, Cleaner | Clean, replace, and secure! |

By sticking to these simple steps, you’ll turn that old lathe into a beast! Let those chips fly!

Common Mistakes to Avoid During Upgrades

Frequent pitfalls beginners encounter and how to avoid them. Importance of following manufacturer guidelines.Upgrading tools can be exciting, but mistakes can spoil the fun. Many beginners overlook manual instructions, which can lead to problems. Always follow the manufacturer’s guidelines. Ignoring them can cause tools to malfunction or even get damaged. Here are some common mistakes to avoid:

- Skipping safety checks

- Using incompatible parts

- Not measuring correctly

- Forgetting to tighten screws

By being careful and following directions, you can keep your upgrades smooth and successful.

What are some common mistakes when upgrading tools?

Common mistakes include not following guidelines, using wrong parts, and skipping safety checks.

Maintenance Tips After Upgrading Your Lathe

Best practices for ensuring longevity and performance. Routine checks to keep your lathe in top shape.After you upgrade your lathe, keeping it in good shape is important. Regular checks help it last longer and work better. Here are some best practices:

- Clean your lathe regularly to remove dust and grime.

- Check the oil levels and add more if it’s low.

- Inspect the belts for wear and replace if needed.

- Ensure all parts are tight and secure.

- Listen for unusual sounds when running your lathe.

Following these tips makes sure your lathe stays strong and performs well. A little care goes a long way!

What’s the best way to maintain a lathe?

To maintain a lathe, clean it regularly and check oil levels often. Also, tighten loose parts and inspect belts for damage. This will help your lathe last longer.

Real-Life Case Studies of Successful Upgrades

Examples of users who have benefited from upgrading their lathes. Insights on how upgrades improved their machining processes.Upgrading lathes has helped many users work smarter, not harder. For instance, Bob, a hobbyist, found smoother cuts after upgrading to a new floor mount lathe. He said, “It’s like trading a tricycle for a Ferrari!” This upgrade boosted his precision and speed. Another user, Jane, noticed that her metal pieces fit together better. The improvements made her projects shine like glitter on a unicorn! Below is a table showcasing their experiences:

| User | Upgrade Benefits |

|---|---|

| Bob | Smoother cuts, increased speed |

| Jane | Better fitting, improved project quality |

These upgrades can turn a simple lathe into a machining superstar!

Cost Analysis: Is the Upgrade Worth It?

Breakdown of costs associated with different upgrades. Comparison of investment vs. potential improvements in productivity.Thinking about making a change? Let’s peek into the costs of upgrading your lathe. Upgrades can range from a few dollars for minor tweaks to thousands for major improvements. It’s like deciding between a slice of pizza or a whole pie—sometimes, you just want the whole thing!

| Upgrade Type | Cost | Productivity Boost |

|---|---|---|

| Basic Parts | $100 | 10% Increase |

| Advanced Features | $1,000 | 50% Increase |

Investing wisely is key. A small investment may improve performance slightly, but a larger one could turn your machine into a productivity beast. In the end, the savings from better efficiency could outweigh the initial costs. Remember, a happy lathe makes for happy projects!

Conclusion

In conclusion, upgrading to a floor mount metal lathe can boost your workshop’s efficiency. It offers stability, precision, and better space management. If you’re considering an upgrade, think about your needs and project types. Explore options that fit your budget and requirements. Start researching today, and take your metalworking skills to the next level! Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Upgrading A Floor Mount Metal Lathe:Upgrading a floor mount metal lathe means making it better or faster. You can add new tools to help you cut metal more easily. Sometimes, you might need a stronger motor for more power. Upgrading also means keeping the lathe clean and checking for any worn-out parts. This way, your lathe works great for your projects!

Sure! Just tell me the question you’d like me to answer, and I’ll be happy to help.

What Are The Most Effective Upgrades To Improve The Precision And Accuracy Of A Floor Mount Metal Lathe?To make your floor mount metal lathe more precise, you can upgrade a few key parts. First, install a better tool holder to keep tools steady. Next, add a digital readout (DRO) to get exact measurements easily. You can also ensure your lathe is properly leveled for better accuracy. Finally, using higher-quality cutting tools can help make cleaner and more precise cuts.

How Can I Enhance The Power And Speed Capabilities Of My Existing Floor Mount Metal Lathe?To make your floor mount metal lathe faster and stronger, you can upgrade the motor. A better motor gives more power. You can also change the gears to allow for faster speed. Lastly, keep your lathe clean and well-oiled. This helps it run smoothly.

What Modern Features Or Technologies Should I Consider When Upgrading My Floor Mount Metal Lathe?When upgrading your floor mount metal lathe, think about adding a digital readout. This helps you see measurements clearly. You might also want a variable speed motor. This lets you change speeds easily for different tasks. Another great upgrade is automatic lubrication. It keeps your machine running smoothly without much effort from you.

Are There Specific Brands Or Models Of Accessories That Are Known To Significantly Enhance The Performance Of A Floor Mount Metal Lathe?Yes, there are some great accessories for floor mount metal lathes. Brands like Jet and Grizzly make good tools that help you work better. You might want to get high-quality cutting tools and a good chuck to hold your metal pieces. Using these accessories can make your lathe work faster and smoother. Always check for reviews to find the best tools for your needs.

What Safety Upgrades Should I Implement To Ensure Better Operation And Reduce Risks While Using A Floor Mount Metal Lathe?To stay safe while using a floor mount metal lathe, you should wear safety goggles to protect your eyes. Use ear protection to save your hearing from loud noises. Keep a first aid kit nearby, just in case. Make sure the area is clean and free of clutter to prevent accidents. Finally, always read the instructions and follow them closely.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Upgrading A Floor Mount Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading a floor mount metal lathe means making it better or faster. You can add new tools to help you cut metal more easily. Sometimes, you might need a stronger motor for more power. Upgrading also means keeping the lathe clean and checking for any worn-out parts. This way, your lathe works great for your projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just tell me the question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Most Effective Upgrades To Improve The Precision And Accuracy Of A Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your floor mount metal lathe more precise, you can upgrade a few key parts. First, install a better tool holder to keep tools steady. Next, add a digital readout (DRO) to get exact measurements easily. You can also ensure your lathe is properly leveled for better accuracy. Finally, using higher-quality cutting tools can help make cleaner and more precise cuts.”}},{“@type”: “Question”,”name”: “How Can I Enhance The Power And Speed Capabilities Of My Existing Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your floor mount metal lathe faster and stronger, you can upgrade the motor. A better motor gives more power. You can also change the gears to allow for faster speed. Lastly, keep your lathe clean and well-oiled. This helps it run smoothly.”}},{“@type”: “Question”,”name”: “What Modern Features Or Technologies Should I Consider When Upgrading My Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When upgrading your floor mount metal lathe, think about adding a digital readout. This helps you see measurements clearly. You might also want a variable speed motor. This lets you change speeds easily for different tasks. Another great upgrade is automatic lubrication. It keeps your machine running smoothly without much effort from you.”}},{“@type”: “Question”,”name”: “Are There Specific Brands Or Models Of Accessories That Are Known To Significantly Enhance The Performance Of A Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some great accessories for floor mount metal lathes. Brands like Jet and Grizzly make good tools that help you work better. You might want to get high-quality cutting tools and a good chuck to hold your metal pieces. Using these accessories can make your lathe work faster and smoother. Always check for reviews to find the best tools for your needs.”}},{“@type”: “Question”,”name”: “What Safety Upgrades Should I Implement To Ensure Better Operation And Reduce Risks While Using A Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stay safe while using a floor mount metal lathe, you should wear safety goggles to protect your eyes. Use ear protection to save your hearing from loud noises. Keep a first aid kit nearby, just in case. Make sure the area is clean and free of clutter to prevent accidents. Finally, always read the instructions and follow them closely.”}}]}