Have you ever watched a lathe in action? It spins and crafts wood or metal into amazing shapes. But what keeps the workpiece steady while it turns? That’s where the lathe follower rest comes in. This handy tool helps support the material, ensuring it doesn’t wobble or break.

Imagine trying to carve a statue from a block of marble without any support. It would be nearly impossible, right? The follower rest acts like a helping hand, keeping everything balanced during work. Most people don’t know this vital part of a lathe exists. But it plays a big role in making sure your projects come out just right.

In this article, we will explore how a lathe follower rest guide works. You’ll learn why it’s so important for both beginner and expert machinists. By the end, you’ll see why every lathe should have one. Are you ready to dive into the world of lathe accessories?

A Complete Lathe Follower Rest Guide For Precision Machining

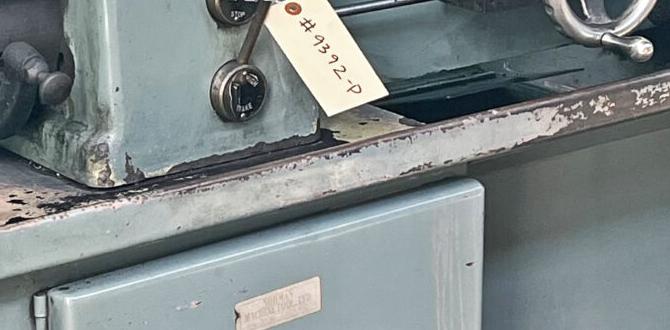

Lathe Follower Rest Guide

Looking for ways to improve your lathe work? The lathe follower rest is your secret tool! It supports long or thin pieces while turning, preventing vibrations and ensuring a smooth finish. By using it properly, you can create precise parts without the risk of mistakes. Did you know that using a follower rest can also boost your lathe’s accuracy? With just a little adjustment, your projects could shine like never before!What is a Lathe Follower Rest?

Definition and purpose of a follower rest in lathe operations. Different types of follower rests: Adjustable vs. Fixed.A lathe follower rest is a tool that helps keep a piece of material stable while a lathe machine works on it. This is important for making precise shapes. There are two main types of follower rests: adjustable and fixed. An adjustable follower rest can change its position, while a fixed one stays in one spot. Each type serves a different purpose, but both are key to getting smooth and accurate results in lathe operations.

What does a lathe follower rest do?

A lathe follower rest provides extra support to longer work pieces. This way, it helps prevent wobbles and bends during machining. It ensures accuracy and improves the quality of your work.

Types of follower rests:

- Adjustable: Can be moved to support different lengths.

- Fixed: Remains in one place for specific tasks.

Benefits of Using a Lathe Follower Rest

Improved precision and accuracy in machining operations. Enhanced support for long and slender workpieces.Using a follower rest on a lathe comes with some neat benefits. First, it boosts precision and accuracy during machining. This means your projects will turn out better, like a pizza with just the right amount of cheese! It also gives extra support for long and slender workpieces, so they don’t wobble around. Picture trying to balance a pencil on your nose—awkward, right? A follower rest makes sure your workpieces stay steady, just like that pencil should be!

| Benefit | Description |

|---|---|

| Improved Precision | Helps create more accurate shapes and cuts. |

| Enhanced Support | Stabilizes long, thin materials to prevent bending. |

Types of Lathe Follower Rests

Description of various follower rest designs (e.g., roller vs. ball bearings). Comparison of features and benefits across different types.Lathe follower rests come in different designs, each with unique features. Two common types are roller and ball bearing rests. Roller rests use cylindrical wheels for smooth movement. Ball bearing rests use small balls to support the workpiece.

Here’s a quick comparison:

- Roller Rests: Good for heavy loads and provide great stability.

- Ball Bearing Rests: Offer smoother movement and reduce friction.

Choosing the right type can improve your lathe work. It can lead to better results and easier handling. Think about what you need before deciding!

What types of follower rests do lathe machines use?

Lathe machines use roller and ball bearing follower rests. Roller rests provide stability, while ball bearing types offer smooth motion.

How to Choose the Right Follower Rest for Your Lathe

Factors to consider: lathe size, workpiece length, and material. Recommendations for specific applications and projects.Choosing the right follower rest for your lathe can feel like picking a favorite pizza topping—everyone has their own idea! First, think about your lathe size; a small lathe needs a snug fit while a bigger one demands sturdiness. Next, consider the workpiece length; shorter pieces won’t need elaborate setups, while longer ones might! Lastly, the material matters too; soft materials need a gentle touch, while metals can handle a firmer grip.

| Application | Recommended Follower Rest |

|---|---|

| Woodturning | Lightweight Rest |

| Metalworking | Heavy-Duty Rest |

| Long Shaft Projects | Adjustable Rest |

Remember, the right follower rest can save you from a wobbly disaster, so choose wisely! Happy turning!

Installing and Adjusting a Lathe Follower Rest

Stepbystep guide on installation process. Tips for proper adjustment for optimal performance.Start by placing the follower rest on the lathe bed. Make sure it fits snugly like a glove on a warm hand. Next, adjust the bolts to secure it. Don’t overtighten—this isn’t a wrestling match! Use the fine adjustment screws to align the follower to your workpiece. Small adjustments yield big results! Remember to perform a quick test run; it’s like a warm-up before a big race.

| Step | Description |

|---|---|

| 1 | Place follower rest on lathe bed. |

| 2 | Secure bolts without overtightening. |

| 3 | Align using adjustment screws. |

| 4 | Test for smooth operation. |

Common Mistakes to Avoid When Using a Follower Rest

Overloading the follower rest. Incorrect positioning and alignment issues.Using a follower rest in machining is like learning to ride a bicycle. You want to avoid common mistakes to keep everything smooth and safe. First, overloading the follower rest can cause disaster. Too much weight makes it wobble like a jelly on a plate! Next, positioning matters. An incorrect setup? It’s like trying to fit a square peg in a round hole—frustrating and ineffective. Take your time to align everything right.

| Mistake | Consequence |

|---|---|

| Overloading | Wobble and poor finishing |

| Wrong Positioning | Inaccurate cuts and wasted time |

Maintenance Tips for Longevity of Your Follower Rest

Routine cleaning and lubrication practices. Signs of wear and when to replace parts.Keeping your follower rest in good shape is easier than you think! Start with regular cleaning. Wipe off dirt and debris often to keep it shiny. Lubricate moving parts to avoid squeaks—no one likes a noisy machine! Look out for signs of wear, like a wobbly base or stubborn clamps. If things look off, it might be time for some new parts. Remember, a happy follower rest means happy turning!

| Signs of Wear | Action Needed |

|---|---|

| Wobbly base | Check screws or replace |

| Stuck clamps | Lubricate or replace |

Conclusion

In summary, a lathe follower rest guide helps keep your workpiece stable during machining. It prevents bending and ensures accuracy. Using this tool can improve your projects and make them easier. If you want to learn more, check out guides or videos online. Try using a follower rest in your next project to see the difference it makes!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Follower Rest Guides:A lathe follower rest guide helps keep a tool steady while it works on a piece of metal or wood. It supports the tool, so it doesn’t move around too much. This makes it easier to cut smooth shapes. You usually use it when making long, thin pieces. It’s super helpful for getting the best results!

Sure! Please give me the question you want answered, and I’ll respond to it in a simple way.

What Is The Primary Function Of A Follower Rest In A Lathe Operation?A follower rest helps keep the long, thin pieces of metal steady while you work on them in a lathe. It supports the metal so it doesn’t wobble or break. This makes it easier to cut and shape the metal correctly. When you use a follower rest, your work looks better and is safer too.

How Does A Follower Rest Improve The Accuracy And Finish Of Turned Parts?A follower rest is a tool that helps keep the part steady while it’s being shaped. When we use it, the part doesn’t wobble or shake. This makes the cuts smoother and more even. You get a better finish and the part fits together perfectly. Using a follower rest is great for making strong and nice-looking pieces!

What Factors Should Be Considered When Selecting A Follower Rest For A Specific Lathe Operation?When you choose a follower rest for a lathe, think about the size of the workpiece. Make sure the follower rest fits the shape and weight. Consider the type of material you’re using, like wood or metal. You should also check how much support you need while cutting. Finally, look at how easy it is to adjust the follower rest during your work.

How Do You Properly Set Up And Adjust A Follower Rest On A Lathe?To set up a follower rest on a lathe, first, make sure the lathe is off. Place the rest close to where you will cut the metal. Adjust the arms of the rest so they touch the workpiece gently. You can move the arms in and out until they fit snugly without pushing too hard. Finally, turn the lathe on and check if everything works smoothly as you cut.

What Are The Differences Between A Steady Rest And A Follower Rest In Lathe Applications?A steady rest and a follower rest are both tools used on a lathe, which is a machine that shapes materials. A steady rest helps hold the workpiece still and keeps it steady while you cut. It doesn’t move with the workpiece. A follower rest, on the other hand, moves with the workpiece. This helps support longer pieces and prevents them from bending as you work on them.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Follower Rest Guides:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe follower rest guide helps keep a tool steady while it works on a piece of metal or wood. It supports the tool, so it doesn’t move around too much. This makes it easier to cut smooth shapes. You usually use it when making long, thin pieces. It’s super helpful for getting the best results!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want answered, and I’ll respond to it in a simple way.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Follower Rest In A Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A follower rest helps keep the long, thin pieces of metal steady while you work on them in a lathe. It supports the metal so it doesn’t wobble or break. This makes it easier to cut and shape the metal correctly. When you use a follower rest, your work looks better and is safer too.”}},{“@type”: “Question”,”name”: “How Does A Follower Rest Improve The Accuracy And Finish Of Turned Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A follower rest is a tool that helps keep the part steady while it’s being shaped. When we use it, the part doesn’t wobble or shake. This makes the cuts smoother and more even. You get a better finish and the part fits together perfectly. Using a follower rest is great for making strong and nice-looking pieces!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Follower Rest For A Specific Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you choose a follower rest for a lathe, think about the size of the workpiece. Make sure the follower rest fits the shape and weight. Consider the type of material you’re using, like wood or metal. You should also check how much support you need while cutting. Finally, look at how easy it is to adjust the follower rest during your work.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Adjust A Follower Rest On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a follower rest on a lathe, first, make sure the lathe is off. Place the rest close to where you will cut the metal. Adjust the arms of the rest so they touch the workpiece gently. You can move the arms in and out until they fit snugly without pushing too hard. Finally, turn the lathe on and check if everything works smoothly as you cut.”}},{“@type”: “Question”,”name”: “What Are The Differences Between A Steady Rest And A Follower Rest In Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A steady rest and a follower rest are both tools used on a lathe, which is a machine that shapes materials. A steady rest helps hold the workpiece still and keeps it steady while you cut. It doesn’t move with the workpiece. A follower rest, on the other hand, moves with the workpiece. This helps support longer pieces and prevents them from bending as you work on them.”}}]}