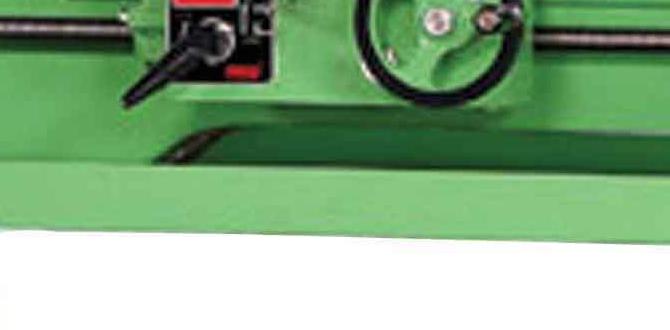

Have you ever wondered how metal lathes create such precise parts? One important factor is the lathe gear ratio. This ratio controls how fast the chuck spins compared to the motor. It is a key element that can make or break your project.

Imagine trying to carve a statue from a block of metal. If your tools aren’t set up right, you might end up with a lump instead of a masterpiece. The right lathe gear ratio helps ensure smooth cuts and perfect finishes.

Did you know that different projects need different setups? For example, turning a small knob requires a different ratio than making large gears. Understanding this can take your metalworking skills to the next level.

In this article, we will explore how to choose the right lathe gear ratio for your metal lathe chuck. Get ready to unlock the secrets of successful machining!

Understanding Lathe Gear Ratio For Metal Lathe Chuck Functions Lathe Gear Ratio Is A Crucial Concept That Significantly Influences The Performance Of A Metal Lathe Chuck. In Manufacturing And Machining, Gear Ratios Determine How The Speed And Torque Of The Lathe’S Spindle Can Be Adjusted, Enabling Operators To Achieve Precision In Their Work. Understanding These Concepts Is Vital For Anyone Working With Metal Lathes, From Novice Hobbyists To Seasoned Professionals. What Is Lathe Gear Ratio? Lathe Gear Ratio Refers To The Relationship Between The Number Of Teeth On Gears Involved In The Lathe’S Drive System. It Determines How Many Revolutions The Spindle Makes For Each Complete Turn Of The Drive Gears. A Higher Gear Ratio Results In More Torque But Less Speed, While A Lower Ratio Allows For Increased Speed But Reduced Torque. Depending On The Project, Selecting The Correct Gear Ratio Is Essential For Optimal Machining Performance. Importance Of Lathe Gear Ratio In Metal Lathes The Gear Ratio Plays An Important Role In Determining The Capabilities Of A Metal Lathe. A Suitable Ratio Allows For Efficient Cutting, Shaping, And Finishing Of Metal Materials, Affecting How Well The Lathe Can Handle Tougher Materials Or Intricate Designs. Furthermore, Adjustments To The Gear Ratio Can Help Operators Manage Their Workflow, Enabling Them To Switch Between Various Operations Without Needing Excessive Re-Calibrations. Choosing The Right Gear Ratio For Your Projects When Working With A Metal Lathe Chuck, It’S Essential To Consider The Specific Materials And Tasks At Hand. Thicker Metals May Require A Higher Torque Ratio To Ensure Smooth And Safe Operations, While Softer Materials Might Allow For Faster Spinning With Less Torque. Operators Should Also Be Familiar With Their Machine’S Specifications To Make Informed Decisions About Gear Adjustments. Conclusion Understanding Lathe Gear Ratio Is Fundamental For Anyone Using A Metal Lathe Chuck. It Directly Impacts The Efficiency And Effectiveness Of Processing Metal. By Carefully Selecting The Appropriate Gear Ratio, Machinists Can Enhance Their Productivity, Quality, And Precision In Various Applications. Whether In A Professional Workshop Or A Home Garage, Mastering Lathe Gear Ratios Leads To Superior Results In Metalworking Projects.

Understanding Lathe Gear Ratio and Metal Lathe Chuck

Lathe gear ratio affects how a metal lathe operates. It determines the speed and torque of the chuck, which holds the workpiece securely. A higher gear ratio means more torque, ideal for tough materials. Want to cut even tricky metals? Choose the right gear ratio! Here’s a fun fact: many beginners underestimate how crucial the gear ratio is for precision work. Knowing this can help you achieve cleaner cuts and smoother finishes.What is a Lathe Gear Ratio?

Definition and importance of gear ratios in lathes. How gear ratios affect spindle speed and torque.Think of the gear ratio as a special set of instructions for your lathe. It tells the machine how fast to spin and how much strength to apply. A higher gear ratio means more torque, but slower speed. This is perfect for heavy-duty tasks. On the other hand, a lower ratio gives you speed, ideal for finer work. Finding the right balance is key to making beautiful projects without losing your mind! Who knew numbers could be so exciting?

| Gear Ratio | Spindle Speed | Torque |

|---|---|---|

| High | Slow | High |

| Low | Fast | Low |

So, whether you’re spinning metal like a magician or crafting wood like a pro, understanding gear ratios makes all the difference!

Types of Gear Ratios in Metal Lathes

Common types of gear ratios used in metal lathes. Advantages and disadvantages of different gear ratio setups.Metal lathes use different gear ratios to change the speed and power of the machine. Common types include:

- Low Gear Ratio: Gives more power but less speed. Good for tough materials.

- High Gear Ratio: Offers higher speed but less torque. Great for easy jobs.

- Variable Gear Ratio: Allows adjusting speed and torque. Very flexible for various tasks.

Advantages: Low gear ratios are perfect for heavy work. High ones help with faster cutting. However, low ratios may slow down simple tasks, while high ratios can struggle with hard materials.

What is a variable gear ratio?

A variable gear ratio allows you to change the speed and force of the lathe easily. This makes it useful for different materials and tasks.

How to Calculate Gear Ratios for Your Lathe

Stepbystep guide to calculating gear ratios. Key formulas and considerations.Calculating gear ratios for your lathe is easier than pie—well, maybe not as tasty, but close! Start with the formula: Gear Ratio = Number of Teeth on Driver Gear / Number of Teeth on Driven Gear. If your driver has 24 teeth and the driven gear has 12, then the gear ratio is 2:1. This means the driver turns twice for each full turn of the other gear. You can create a handy table to keep track of the teeth counts:

| Gear Type | Number of Teeth |

|---|---|

| Driver Gear | 24 |

| Driven Gear | 12 |

Remember, the bigger the driver gear, the more torque you get—just like eating your veggies gives you strong muscles!

Selecting the Right Chuck for Your Metal Lathe

Factors to consider when choosing a chuck. How gear ratio impacts chuck performance and versatility.Choosing a chuck for your metal lathe is important. Several factors can help you decide. First, think about the size, which must fit your lathe. Next, consider the material, as some chucks are stronger than others. Also, look at the gear ratio since it affects how well the chuck performs.

- Performance: A good gear ratio improves speed and control.

- Versatility: It lets you use different workpieces.

- Tightening mechanism: This ensures your projects are securely held.

Keep these tips in mind to make the best choice!

What should I consider when choosing a chuck?

Look for size, material, gear ratio, and tightening mechanism for better performance.

Maintenance Tips for Lathe Gear and Chuck

Best practices for maintaining lathe gears. Chuck maintenance tips to enhance longevity and efficiency.Keeping your lathe gears and chuck in top shape is like giving your machine a spa day! Start by regularly checking the gears for dirt and dust. If grime builds up, it can lead to trouble down the road. For your chuck, clean it often and ensure it grabs onto materials tightly. Remember, a happy chuck makes for smoother work! Here’s a quick maintenance table:

| Maintenance Task | Frequency |

|---|---|

| Inspect Gears | Weekly |

| Clean Chuck | After Every Use |

| Lubricate Gears | Monthly |

| Check Chuck Tightness | Before Each Project |

Taking these simple steps will not only improve your lathe’s efficiency but also extend its life. And who doesn’t want a long-lasting machine? It’s the best kind of relationship!

Common Problems and Troubleshooting with Gear Ratios and Chucks

Identifying issues related to gear ratios and their effects. Common chuckrelated problems and solutions.Gear ratios and chucks might sound complex, but don’t worry! Issues can pop up like popcorn. For example, a wrong gear ratio can slow you down or make your machine super noisy. That’s like trying to run in flip-flops! Common chuck problems include wobbly grips. Wobbling means your workpiece could dance off the lathe. Luckily, you can fix it by tightening the chuck or checking for damages. Here’s a handy table for quick fixes:

| Problem | Solution |

|---|---|

| Wrong gear ratio | Adjust settings |

| Wobbly chuck | Tighten or replace |

| Slipping workpiece | Check jaws for wear |

With a few adjustments, you can keep your lathe running smoothly. Just think of it as giving your lathe a little tune-up—like a musical instrument!

Upgrading Your Lathe Gear Ratio and Chuck

Indicators that suggest an upgrade is needed. Considerations for upgrading to improve performance.Upgrading your lathe can make a big difference. Look for these signs:

- Poor cutting quality

- Frequent tool wear

- Slower production speed

- Limited project options

When considering an upgrade, think about performance. A better lathe gear ratio boosts speed and torque. Upgrading the metal lathe chuck improves grip and precision. These changes can help you work faster and create better pieces. Are you ready to improve your lathe?

What signs indicate it’s time for an upgrade?

Poor performance, frequent maintenance, and limited machining options suggest an upgrade. Watch for these signs to enhance your work.

Conclusion

In summary, understanding lathe gear ratios helps you work with metal lathe chucks more effectively. A proper gear ratio improves speed and accuracy for your projects. You can achieve better results by adjusting these settings. Explore more about gearing systems or practice using lathe chucks to enhance your skills. Dive into your next project with confidence!FAQs

What Is The Significance Of Gear Ratio In The Operation Of A Metal Lathe Chuck?The gear ratio helps us control how fast the lathe chuck spins. A higher gear ratio means the chuck turns faster. This is important when we want to shape or cut metal. It also helps us apply different amounts of power, making our work easier. So, the gear ratio is key to getting the job done right!

How Can You Calculate The Gear Ratio For A Specific Metal Lathe Setup?To find the gear ratio for a metal lathe, you first need to look at the gears. Count the teeth on the driver gear, which is the one that gets turned by the motor. Then count the teeth on the driven gear, which is the gear that gets turned by the driver gear. Divide the number of teeth on the driver gear by the number of teeth on the driven gear. This gives you the gear ratio, telling you how many times the motor turns compared to the lathe.

What Are The Common Gear Ratios Used In Metal Lathes, And How Do They Affect Machining Speed And Torque?Common gear ratios in metal lathes are often 1:1, 2:1, or 4:1. A 1:1 ratio gives you more speed but less power. A 4:1 ratio provides more torque, which helps cut tougher materials. So, if you want to go fast, you pick a lower ratio. If you need to cut something hard, choose a higher ratio.

How Do Adjustments To The Gear Ratio Influence The Performance And Precision Of A Lathe Chuck During Machining?When you change the gear ratio on a lathe chuck, it can make the machine work faster or slower. A faster speed can help you cut materials quickly, but it might be less accurate. If you slow it down, you can get better precision, meaning your cuts will be cleaner and more exact. Adjusting the gear ratio helps you find the right balance between speed and accuracy for your project.

What Are The Potential Consequences Of Using An Incorrect Gear Ratio On A Metal Lathe Chuck?Using the wrong gear ratio on a metal lathe chuck can cause problems. You might end up with uneven cuts, which makes your work look bad. The lathe could also shake or vibrate too much, making it hard to control. This can even damage the machine over time. Always use the right gear ratio to keep everything running smoothly.