Have you ever seen a metal lathe in action? It’s like watching a magician at work! With just a few adjustments, a simple piece of metal transforms into something amazing. But one of the secrets behind this magic is the lathe gear ratio.

So, what exactly is a gear ratio? Think of it like the number of times you turn a handle compared to how far the tool moves. It affects speed and power. A good metal lathe controller helps manage this ratio to create perfect cuts every time. Is there a better way to learn about how it all works?

As you dive into the world of lathes, you’ll discover surprising facts that can improve your skills. Did you know that adjusting the gear ratio can turn a tedious task into a fun project? It’s true! Understanding these details opens new opportunities for anyone interested in metal crafting.

Join us on this journey to explore the exciting relationship between gear ratios and metal lathe controllers. You’ll be amazed at what you can create!

Understanding Lathe Gear Ratio For Metal Lathe Controller

Understanding Lathe Gear Ratio Metal Lathe Controller

Lathe gear ratio is crucial for controlling the speed and torque of a metal lathe. This controller helps adjust the gear ratio, allowing users to create precise cuts. By changing the ratio, you can speed up or slow down the lathe’s operation easily. Imagine shaping a piece of metal as effortlessly as slicing through butter. With the right gear ratio, even beginners can achieve expert-level results. Isn’t it exciting to think about what you could create?Understanding Gear Ratios in Metal Lathes

Definition of gear ratio. Importance of gear ratios in lathe performance.Gear ratio tells us how many times the spindle turns for every turn of the motor. It’s like counting how many friends you can fit in a tiny car! In metal lathes, gear ratios help ensure smooth operation. They affect the speed and torque needed for cutting metal. This means the right ratio can make the difference between a flawless cut and a failed attempt. Who wants that, right? Even a squirrel can figure out, more torque means better cuts!

| Gear Ratio | Spindle Speed | Torque |

|---|---|---|

| 1:1 | Slow | High |

| 2:1 | Faster | Medium |

| 4:1 | Very Fast | Low |

How Gear Ratios Affect Lathe Operations

Influence on cutting speed. Impact on torque and efficiency.Gear ratios play a big role in how a lathe works. They help control cutting speed, which can change the way metal is shaped. A higher gear ratio often means a slower speed, making those cuts smoother and safer. On the flip side, lower gears boost the torque. This means you can handle tougher materials without breaking a sweat—or your machine!

| Gear Ratio | Cutting Speed | Torque | Efficiency |

|---|---|---|---|

| High | Slow | Low | Less Power |

| Low | Fast | High | More Power |

Finding the right balance is key. Think of it like riding a bike: too fast, and you crash; too slow, and your friends leave you behind. A good controller helps you manage these ratios for perfect cuts every time!

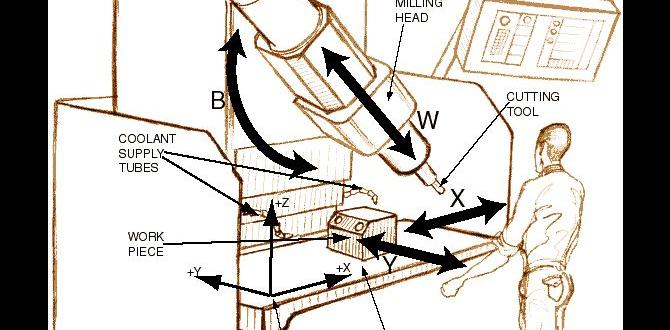

Components of a Metal Lathe Controller

Key functions of a lathe controller. Types of metal lathe controllers available.A metal lathe controller has several key functions that make it valuable. It helps to manage the speed and position of the cutting tool. This ensures accurate shaping of metal. Different types of metal lathe controllers are available:

- **Manual Controllers** – Easy to use with basic functions.

- **Digital Controllers** – Offer advanced features like programming and automation.

- **CNC Controllers** – Provide precise control, often used in industrial settings.

Choosing the right controller can boost your lathe’s performance.

What is the role of a metal lathe controller?

The role of a metal lathe controller is to control speed and precision during metal shaping tasks. It plays an important role in achieving high-quality results.

Calculating the Ideal Gear Ratio for Your Lathe

Stepbystep calculation guide. Factors to consider for optimal gear ratios.Finding the right gear ratio for your lathe is important. Here’s how to calculate it step by step. First, measure the diameter of your workpiece. Next, choose the speed you want. Then, identify the motor speed of your lathe. Divide the motor speed by the desired speed. This gives you the gear ratio.

Consider these factors for the best gear ratio:

- Workpiece size

- Material type

- Desired finish quality

These points will help you find the best setup for your lathe.

What is a good gear ratio for a lathe?

A good gear ratio for a lathe varies. It often falls between 4:1 to 6:1 depending on the job and materials.

Using these ratios can help achieve smooth cuts.

Adjusting Gear Ratios on Metal Lathes

Methods to change gear ratios effectively. Recommendations for different materials and projects.Changing gear ratios on metal lathes can make your work easier and more precise. Here are some simple methods you can use:

- Check your manual for the correct settings.

- Use a wrench to shift gears safely.

- Practice switching while the lathe is off.

Different materials and projects need different gear setups. For softer metals, lower ratios work best. For harder materials, higher ratios give better results. Consider the project type and choose the right ratio to succeed!

What are the best practices for adjusting gear ratios?

To adjust gear ratios correctly, it’s key to consult your lathe manual and practice careful switching in a safe environment. Using the right ratio for the material can improve your results significantly!

Common Challenges with Gear Ratios in Metal Lathes

Typical issues encountered. Solutions and troubleshooting tips.Gear ratios can pose several challenges for metal lathe users. Common issues include incorrect settings, noise during operation, and inconsistent cuts. These problems can lead to frustration and wasted materials.

Here are some solutions:

- Check the gear ratio settings before starting.

- Lubricate moving parts to reduce noise.

- Adjust the cutting speed for smoother operations.

By identifying these challenges and applying these easy fixes, you can enjoy better results with your lathe.

What are the common causes of gear ratio problems?

Common causes include incorrect gear alignment and damaged components. Always inspect your machine regularly to avoid issues.

Tips for Troubleshooting:

- Listen for unusual sounds.

- Evaluate cutting performance.

- Consult the manual for adjustments.

Staying proactive will keep your lathe running smoothly!

Advanced Techniques for Gear Ratio Optimization

Enhancing performance through customization. Using software and tools for precision adjustments.Customizing your lathe gear ratio can greatly enhance performance. By fine-tuning settings, you make your machine work better for your needs. Using software and tools allows for precise adjustments. This leads to smoother operation and improved results. Think of it like tuning a musical instrument for the best sound.

- Choose the right software for adjustments.

- Test different gear ratios to find the best fit.

- Record your settings for quick changes.

How do advanced settings improve lathe performance?

Advanced settings allow users to customize functions for specific tasks. This means smoother cuts, less wear, and better finished products. Precision leads to success!

Future Trends in Metal Lathe Gear Ratios and Controllers

Emerging technology in lathe machinery. Predictions for advancements in gear ratio management.New technology is changing metal lathes fast. Smart controllers are helping machines work better. These controllers can adjust lathe gear ratios automatically. This means operators can make parts more accurately and quickly. In the future, we might see even more improvements, like:

- More user-friendly interfaces

- Better energy efficiency

- Advanced sensors for accurate monitoring

These advancements will help workers create high-quality products with ease.

What advancements can we expect in lathe technology?

Predictions include smarter gear management tools, better control systems, and new materials for lathes. These changes will make metal lathes more efficient and user-friendly, transforming manufacturing.

Conclusion

In summary, understanding the lathe gear ratio is essential for effective metal lathe control. It directly affects speed and precision in your projects. We can use the right gear ratio to improve our results. If you’re interested, explore different controllers to find what works best for you. Experimenting will help you learn and get better!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Controllers:Sure! Here are some simple answers about lathe gear ratios and controllers. 1. What is a lathe gear ratio? A lathe gear ratio is how fast the lathe machine turns the material. A higher ratio means faster spinning! 2. Why is the gear ratio important? The gear ratio helps you choose the right speed for making different shapes. It helps us work better. 3. How do you change the gear ratio? You can change the gear ratio by swapping the gears on the machine. This lets you adjust the speed. 4. What is a metal lathe controller? A metal lathe controller is a device that helps you control the lathe’s speed and movements easily. 5. How can I use a controller? You can use a controller by pressing buttons to set the speed. It helps make your work smoother!

Sure! Please share the question you’d like me to answer.

What Is The Significance Of Gear Ratio In The Operation Of A Metal Lathe, And How Does It Affect Cutting Speed And Torque?The gear ratio helps a metal lathe change how fast it spins the metal. A higher gear ratio means the lathe spins faster, which gives you more cutting speed. However, this can reduce torque, which is the power to push through tough metal. So, if you want to cut quickly, you might have less power. Choosing the right gear ratio is key for good, smooth cuts.

How Can A Metal Lathe Controller Be Used To Adjust Gear Ratios For Different Machining Tasks?You can use a metal lathe controller to change gear ratios by selecting new settings. Gear ratios help control how fast the metal spins. When you adjust these settings, you make it easier to carve different shapes. For finer details, you choose a slower speed. For bigger cuts, a faster speed works better. This helps you do different tasks more easily!

What Are The Common Gear Ratios Found In Metal Lathes, And How Do They Influence The Lathe’S Performance?Common gear ratios in metal lathes include 1:1, 2:1, and 4:1. Gear ratios help decide how fast the lathe spins. A higher number means faster spinning, which can help make things quicker but less smooth. A lower number makes the lathe slower, which can help you make cleaner cuts. So, different ratios change how the lathe works for various tasks.

How Do Digital Controllers Enhance The Precision And Ease Of Adjusting Gear Ratios In Modern Metal Lathes Compared To Traditional Mechanical Methods?Digital controllers make it easier to change gear ratios in modern metal lathes. Instead of turning knobs or levers, you just push buttons. This helps you get the exact setting you want quickly. You can also see the exact numbers on a screen, which helps avoid mistakes. Overall, it’s faster and more accurate than old methods.

What Factors Should Be Considered When Selecting A Metal Lathe Controller That Includes Gear Ratio Adjustment Capabilities?When choosing a metal lathe controller with gear ratio adjustment, we should think about a few important things. First, look for how easy it is to understand and use. You want controls that are simple and clear. Next, check if the controller can work with different types of lathes. Lastly, think about how accurate it is. Good accuracy helps create better finished products.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Controllers:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some simple answers about lathe gear ratios and controllers. 1. What is a lathe gear ratio? A lathe gear ratio is how fast the lathe machine turns the material. A higher ratio means faster spinning! 2. Why is the gear ratio important? The gear ratio helps you choose the right speed for making different shapes. It helps us work better. 3. How do you change the gear ratio? You can change the gear ratio by swapping the gears on the machine. This lets you adjust the speed. 4. What is a metal lathe controller? A metal lathe controller is a device that helps you control the lathe’s speed and movements easily. 5. How can I use a controller? You can use a controller by pressing buttons to set the speed. It helps make your work smoother!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratio In The Operation Of A Metal Lathe, And How Does It Affect Cutting Speed And Torque?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio helps a metal lathe change how fast it spins the metal. A higher gear ratio means the lathe spins faster, which gives you more cutting speed. However, this can reduce torque, which is the power to push through tough metal. So, if you want to cut quickly, you might have less power. Choosing the right gear ratio is key for good, smooth cuts.”}},{“@type”: “Question”,”name”: “How Can A Metal Lathe Controller Be Used To Adjust Gear Ratios For Different Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a metal lathe controller to change gear ratios by selecting new settings. Gear ratios help control how fast the metal spins. When you adjust these settings, you make it easier to carve different shapes. For finer details, you choose a slower speed. For bigger cuts, a faster speed works better. This helps you do different tasks more easily!”}},{“@type”: “Question”,”name”: “What Are The Common Gear Ratios Found In Metal Lathes, And How Do They Influence The Lathe’S Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common gear ratios in metal lathes include 1:1, 2:1, and 4:1. Gear ratios help decide how fast the lathe spins. A higher number means faster spinning, which can help make things quicker but less smooth. A lower number makes the lathe slower, which can help you make cleaner cuts. So, different ratios change how the lathe works for various tasks.”}},{“@type”: “Question”,”name”: “How Do Digital Controllers Enhance The Precision And Ease Of Adjusting Gear Ratios In Modern Metal Lathes Compared To Traditional Mechanical Methods?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Digital controllers make it easier to change gear ratios in modern metal lathes. Instead of turning knobs or levers, you just push buttons. This helps you get the exact setting you want quickly. You can also see the exact numbers on a screen, which helps avoid mistakes. Overall, it’s faster and more accurate than old methods.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Metal Lathe Controller That Includes Gear Ratio Adjustment Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe controller with gear ratio adjustment, we should think about a few important things. First, look for how easy it is to understand and use. You want controls that are simple and clear. Next, check if the controller can work with different types of lathes. Lastly, think about how accurate it is. Good accuracy helps create better finished products.”}}]}