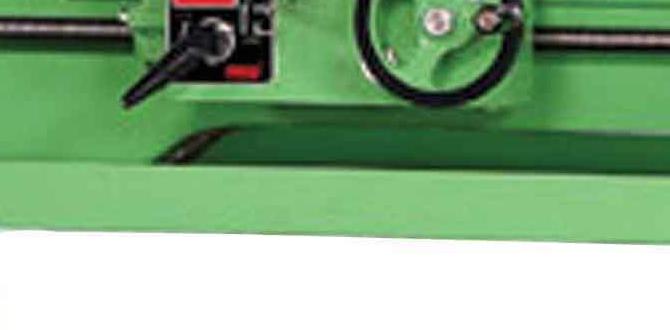

Have you ever wondered how a simple piece of metal can become a finely crafted part? It all starts with machines like the metal lathe. This powerful tool shapes and molds metal with precision. But what makes it work so well? One important factor is the lathe gear ratio.

The lathe gear ratio determines how fast the metal turns. This affects how the tool cuts and shapes the metal. For a smooth cut, finding the right gear ratio is key. Too fast, and things can go wrong. Too slow, and the job takes forever.

Another important element is coolant. Using the right coolant helps keep the metal and tools cool. This prevents damage and makes cutting easier. Imagine trying to carve a block of ice with a hot knife!

So, why should you care about lathe gear ratio and coolant? Understanding these concepts can make your projects more successful. Whether you’re a beginner or an expert, knowing how they work together helps you create better results. Let’s dive deeper into these tools and see how they can improve your metalworking!

Understanding Lathe Gear Ratio And Metal Lathe Coolant

Understanding Lathe Gear Ratio and Metal Lathe Coolant

Lathe gear ratio affects how fast your metal lathe works. A higher gear ratio means faster spinning, which is great for some tasks. Did you know the right coolant can make a big difference, too? It keeps the lathe cool and reduces wear. Choosing the correct gear ratio and coolant boosts efficiency and prolongs machine life. Curious about what happens if you choose poorly? It can lead to damage and extra costs!What is a Lathe Gear Ratio?

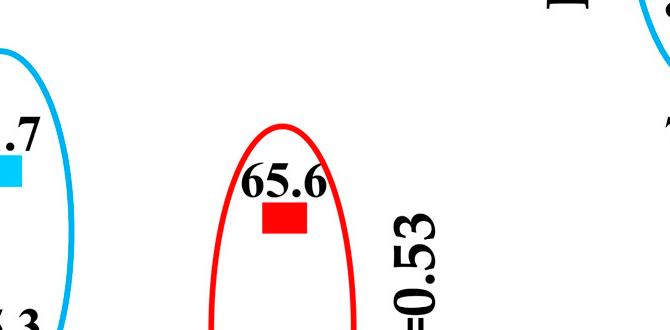

Definition of gear ratio in the context of lathes. Importance of gear ratio in machining accuracy and efficiency.A lathe gear ratio is a way to measure how fast or slow the lathe spins. It compares the number of teeth on two gears. A higher gear ratio means the lathe turns faster, while a lower ratio gives more torque. This balance is important for machining accuracy and efficiency.

- Higher ratios increase speed and productivity.

- Lower ratios improve control and precision.

- Finding the right ratio helps create better parts.

Why is gear ratio important in lathes?

The gear ratio affects how well a lathe works. A good ratio leads to better cuts and smoother finishes. It helps the machinist make parts that fit perfectly. Choosing the right gear ratio saves time and materials.

The Mechanics of Lathe Gear Ratios

Explanation of how gear ratios function in a lathe. Types of gears used in lathes and their impact on performance.Lathe gear ratios are important for how a lathe works. They help control the speed and torque of the machine. Higher gear ratios make the lathe go faster, while lower ratios provide more power. Lathes use different gears to suit various tasks. Here are some common types:

- **Spur gears**: Simple and effective for most tasks.

- **Bevel gears**: Change direction of motion.

- **Helical gears**: Smooth operation and better torque.

The right gear choice can improve a lathe’s performance, making it more efficient and effective.

What do lathe gear ratios affect?

Lathe gear ratios affect speed and power. Changing the ratio impacts how quickly the lathe spins and how strong the cuts are.

Choosing the Right Gear Ratio for Your Project

Factors to consider when selecting a gear ratio. Common gear ratios used for different materials and operations.Choosing the correct gear ratio is key for any lathe project. You must think about what material you’re using. Harder materials need a different approach than softer ones. Common gear ratios, like 1:1 and 2:1, suit many operations. For metals, a higher ratio often works best because it gives better control. On the other hand, softer materials might need lower ratios for smoother cuts.

| Material Type | Recommended Gear Ratio |

|---|---|

| Soft Metals | 1:1 – 2:1 |

| Hard Metals | 3:1 – 4:1 |

| Wood | 1:1 |

Keep this in mind: a good gear ratio can save time and make your cuts neater. Choose wisely, and your lathe will thank you with precise results! Who knew math could be so helpful in the workshop?

The Role of Coolant in Metal Lathing

Definition and purpose of coolant in metalworking. Benefits of using coolant during lathe operations.Coolant is a special liquid that helps during metalworking on lathes. Its main job is to keep things cool. When you cut metal, it can get super hot—think of it like frying an egg! Coolant reduces heat and cuts friction, like a superhero cape for your machine.

Using coolant has many benefits. It makes your tools last longer and keeps them sharp. Plus, it helps prevent rust! Without it, the metal might turn into a hot mess. So, adding coolant is like giving your lathe a refreshing drink during a workout!

| Benefits of Coolant | Description |

|---|---|

| Reduces Heat | Cools the cutting area, preventing overheating. |

| Extends Tool Life | Keeps tools sharper and lasts longer. |

| Prevents Rust | Stops corrosion in your metal parts. |

How to Apply Coolant Effectively

Techniques for applying coolant during lathe operations. Best practices to enhance cooling efficiency and tool lifespan.Coolant is a superstar in lathe operations. It cools down the tool and workpiece, keeping everything running smoothly. Using a fine spray works best. It gets into those tight spots where heat likes to hide. Aim the spray directly at the cutting area. Remember to check the coolant level often. A low coolant level is like having a flat tire — it slows everything down!

To help you remember the best ways to apply coolant, here’s a quick table:

| Technique | Description |

|---|---|

| Direct Application | Aim the spray at the cutting zone for maximum cooling. |

| Consistent Flow | Keep the coolant flowing throughout the cut. |

| Check Levels | Keep an eye on coolant levels to avoid overheating. |

By applying coolant effectively, you’ll not only keep your tools sharp, but you’ll also make them feel loved. Happy tools last longer, and that means less time fixing and more time creating!

Common Mistakes to Avoid with Gear Ratios and Coolants

Frequent errors operators make related to gear ratios. Misuse of coolant and its negative impacts on machining processes.Many operators make simple mistakes with gear ratios. One common error is using the wrong ratio, which can slow down machines or even break them. It’s like trying to fit a square peg in a round hole! Also, coolant can be misused. Not using enough coolant can lead to overheating, while too much can cause messy workspaces. It’s all about balance, like a well-made sandwich. Here’s a quick view of these common mistakes:

| Error Type | Description |

|---|---|

| Incorrect Gear Ratio | Leads to slower operations or equipment damage. |

| Coolant Misuse | Too little causes overheating; too much makes a mess. |

Remember, proper gear ratios and coolant use keep your lathe happy and running smoothly! After all, a well-maintained machine makes better metal products.

Maintenance of Gear Ratios and Coolant Systems

Importance of regular maintenance for optimal performance. Tips on how to maintain both gear and coolant systems effectively.Regular maintenance keeps gear ratios and coolant systems running well. It helps machines work better and last longer. Follow these simple tips:

- Check oil levels and replace when needed.

- Clean coolant tanks to prevent sludge buildup.

- Inspect gears for wear and tear regularly.

- Use proper coolant to avoid overheating.

Keeping everything in top shape makes your work smooth and efficient. Remember, a little care goes a long way!

How often should you maintain the gear and coolant systems?

It’s best to check gear and coolant systems every month. Regular checks ensure smooth operation and help catch problems early.

Conclusion

In summary, understanding lathe gear ratios helps you control cutting speeds effectively. Using coolant is vital for smooth operation and longer tool life. Together, they improve your metalworking projects. Remember, you can explore more about these topics to boost your skills. Dive deeper and experiment with gear ratios and coolant types for the best results!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio, Metal Lathe, And Coolant:Sure! A lathe is a machine that helps us shape metal. The gear ratio tells us how fast the lathe spins. This helps us make parts of different sizes and shapes. We also use coolant to keep the metal cool while we work. It helps make smooth cuts and keeps the tool from getting too hot.

Sure! Please provide the question you want me to answer.

How Does The Gear Ratio Of A Metal Lathe Affect Its Cutting Speed And Torque During Machining Operations?The gear ratio on a metal lathe helps control its speed and strength. A high gear ratio makes the lathe spin fast, which gives a quick cutting speed. But it can make the cutting tool weaker, reducing torque. A low gear ratio does the opposite: it makes the lathe slower but stronger. By changing the gear ratio, you can find the best balance for your work.

What Types Of Coolant Are Commonly Used In Metal Lathes, And How Do They Contribute To The Machining Process?Metal lathes use different types of coolants, like water-based liquids and oil. Water-based coolants help keep things cool and clean, while oil-based coolants are thicker and better at cutting. These coolants help keep the metal from getting too hot and help the cutting tools last longer. They make it easier for us to shape the metal without breaking anything.

How Can Improper Gear Ratios Impact The Surface Finish And Precision Of Parts Produced On A Lathe?If the gear ratios on a lathe are wrong, it can cause problems. You might see rough or uneven surfaces on the parts. This happens because the tool can move too fast or too slow. When the speed is off, it’s hard to make precise cuts. So, you end up with parts that don’t look or fit right.

What Are The Best Practices For Applying Coolant On A Metal Lathe To Enhance Tool Life And Reduce Friction?To use coolant on a metal lathe, first, choose the right type of coolant for your work. Make sure to apply it directly to the cutting tool while it works. You should keep the area clean to prevent dirt from mixing with the coolant. Always check the coolant level and refill it when needed. This helps your tool last longer and reduces friction.

How Do Different Gear Ratios Influence The Types Of Materials That Can Be Effectively Machined On A Metal Lathe?Different gear ratios change how fast the metal lathe spins. If the lathe spins slowly, you can work with harder metals. If it spins faster, you can easily shape softer materials. This helps us choose the right speed for the material we are using. So, the gear ratio helps us be better at machining different materials!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio, Metal Lathe, And Coolant:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. The gear ratio tells us how fast the lathe spins. This helps us make parts of different sizes and shapes. We also use coolant to keep the metal cool while we work. It helps make smooth cuts and keeps the tool from getting too hot.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “How Does The Gear Ratio Of A Metal Lathe Affect Its Cutting Speed And Torque During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio on a metal lathe helps control its speed and strength. A high gear ratio makes the lathe spin fast, which gives a quick cutting speed. But it can make the cutting tool weaker, reducing torque. A low gear ratio does the opposite: it makes the lathe slower but stronger. By changing the gear ratio, you can find the best balance for your work.”}},{“@type”: “Question”,”name”: “What Types Of Coolant Are Commonly Used In Metal Lathes, And How Do They Contribute To The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use different types of coolants, like water-based liquids and oil. Water-based coolants help keep things cool and clean, while oil-based coolants are thicker and better at cutting. These coolants help keep the metal from getting too hot and help the cutting tools last longer. They make it easier for us to shape the metal without breaking anything.”}},{“@type”: “Question”,”name”: “How Can Improper Gear Ratios Impact The Surface Finish And Precision Of Parts Produced On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the gear ratios on a lathe are wrong, it can cause problems. You might see rough or uneven surfaces on the parts. This happens because the tool can move too fast or too slow. When the speed is off, it’s hard to make precise cuts. So, you end up with parts that don’t look or fit right.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Applying Coolant On A Metal Lathe To Enhance Tool Life And Reduce Friction?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use coolant on a metal lathe, first, choose the right type of coolant for your work. Make sure to apply it directly to the cutting tool while it works. You should keep the area clean to prevent dirt from mixing with the coolant. Always check the coolant level and refill it when needed. This helps your tool last longer and reduces friction.”}},{“@type”: “Question”,”name”: “How Do Different Gear Ratios Influence The Types Of Materials That Can Be Effectively Machined On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different gear ratios change how fast the metal lathe spins. If the lathe spins slowly, you can work with harder metals. If it spins faster, you can easily shape softer materials. This helps us choose the right speed for the material we are using. So, the gear ratio helps us be better at machining different materials!”}}]}