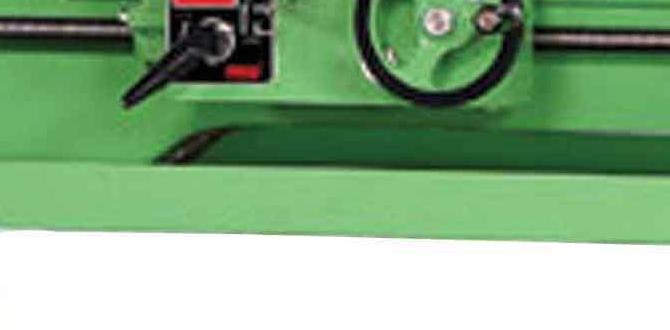

Have you ever wondered how a metal lathe can shape metal so precisely? One of the secrets lies in the lathe gear ratio. Understanding this ratio helps you know how fast your lathe turns. It also shows how much power you can get from your machine.

Imagine trying to slow down a big car. You’d need a strong brake, right? The same principle applies to a lathe foot brake. This part helps you stop the machine quickly and safely. It’s important for both beginners and experts.

Here’s a fun fact: a well-tuned lathe with the right gear ratio can make smooth cuts that seem almost magical. It’s all about balance and control. Wouldn’t it be amazing to master those skills and create your own metal art?

In this article, we’ll explore lathe gear ratios and the role of the metal lathe foot brake. Get ready to discover how these elements work together to create amazing metal creations!

Understanding Lathe Gear Ratio And Metal Lathe Foot Brake

Understanding Lathe Gear Ratio and Metal Lathe Foot Brake

Lathe gear ratio affects how fast the lathe spins. A higher gear ratio means faster speeds for different tasks. Did you know that adjusting the gear ratio can lead to smoother finishes? The metal lathe foot brake plays a crucial role too. It helps stop the lathe quickly and safely. Learning about these components can make your lathe projects easier and more efficient. Are you ready to improve your machining skills?What is Gear Ratio in Metal Lathes?

Definition of gear ratio and its significance in metal lathes. Explanation of how gear ratios affect cutting speed and torque.The gear ratio is a measurement that explains how many times the lathe will turn its spindle for every turn of the motor. Think of it as the number of turns you get for every trip around the playground! A higher gear ratio means more speed, while a lower one offers more torque, or power. This balance is important when cutting metal. You want speed for a clean finish, but power is key for tough materials. So, choosing the right gear can make the difference between a smooth cut and a wobbly mess!

| Gear Ratio | Effect on Cutting |

|---|---|

| High | Increases speed |

| Low | Boosts torque |

How to Calculate Lathe Gear Ratio

Stepbystep guide on calculating gear ratio for different lathe models. Common formulas and examples for practical understanding.Ready to tackle the gear ratio? First, grab your calculator and take a deep breath. It’s easier than it sounds! Start by counting the teeth on the driving gear and the driven gear. The formula is simple: Gear Ratio = Teeth on Driving Gear / Teeth on Driven Gear. For example, if your driving gear has 10 teeth and the driven gear has 40, your gear ratio is 1:4. This means the driving gear spins four times for every single spin of the driven gear. Easy, right? Just remember to keep your toes away from the foot brake while doing the math!

| Driving Gear Teeth | Driven Gear Teeth | Gear Ratio |

|---|---|---|

| 10 | 40 | 1:4 |

| 20 | 60 | 1:3 |

| 15 | 30 | 1:2 |

Now, go forth and calculate those gear ratios like a pro!

Foot Brake Mechanisms in Metal Lathes

Description of foot brake functionality and its role in lathe operation. Safety benefits provided by foot brakes during metalworking.Foot brakes on metal lathes work like super-smart shoes for your machine! When you push the foot pedal, it quickly stops the lathe. This is important because it keeps everyone safe. Nobody wants to be a surprise star in the *”I Lost a Finger”* show. A foot brake ensures quick stops, reducing accidents and ensuring a safe workspace.

| Functionality | Safety Benefits |

|---|---|

| Instant stop of lathe | Reduces chance of injury |

| Easy access while working | Improves operator control |

| Increased efficiency | Minimizes repair costs |

In fact, a study shows that machines with proper foot brakes see up to 30% fewer accidents. So, a simple push on that pedal can save a toe or two!

Integrating Gear Ratio Adjustment with Foot Brake Usage

Discussion on the relationship between gear ratio adjustments and foot brake application. Advantages of efficient gear and brake coordination in enhancing productivity.Adjusting the gear ratio on a lathe can make a big difference. When you change the gears, it’s like switching from jogging to sprinting. A foot brake lets you stop quickly. Combining these two can boost your productivity. Imagine racing to the finish line and hitting the brakes at the right moment. It saves time and energy! Efficient gear and brake use leads to smoother operations. Who wouldn’t want to get more done with less effort?

| Advantage | Description |

|---|---|

| Time Savings | Faster adjustments help you finish jobs quicker. |

| Increased Safety | Quick braking lowers the risk of accidents. |

| Improved Quality | Better control leads to higher quality work. |

Common Issues with Lathe Gear Ratios and Foot Brakes

Identification of common problems faced by operators, such as gear slippage and brake failure. Tips for troubleshooting and maintaining optimal performance.Operators may face several problems with lathe gear ratios and foot brakes. Common issues include gear slippage and brake failure. Slippage happens when gears don’t mesh well, causing work to feel uneven. Brake failure can make it hard to stop safely. To keep machines running well, follow these tips:

- Check gear teeth for damage.

- Lubricate moving parts regularly.

- Test foot brakes frequently for responsiveness.

What are common problems with lathe gear ratios and foot brakes?

Common issues include gear slippage and brake failure, which can affect machine performance. Regular maintenance helps to avoid these problems.

Best Practices for Operating Metal Lathes with Gear Ratios and Foot Brakes

Recommended techniques for maximizing efficiency and safety during operation. Regular maintenance tips for gear systems and brake components.To operate metal lathes safely and efficiently, start by ensuring the gear ratios are set correctly for your task. Use the foot brake gently. It’s like giving your machine a little hug to slow it down! Regularly check and clean the gear system and brake components. Cleanliness is close to lathe-iness! A simple monthly scrub can help avoid costly repairs. Use this maintenance schedule:

| Maintenance Task | Frequency |

|---|---|

| Clean gear components | Monthly |

| Inspect foot brake | Every 3 months |

By following these tips, you keep your machine happy and running smoothly—just like a well-oiled dancing robot!

Conclusion

In summary, understanding lathe gear ratios helps you control speed and power effectively. A metal lathe’s foot brake ensures safety during operations. Always adjust the gear ratio for different tasks. We encourage you to read more about lathe maintenance and operation tips to enhance your skills. Stay safe and keep practicing on your projects for better results!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio, Metal Lathe, And Foot Brake:What is a lathe gear ratio? A lathe gear ratio tells us how fast the lathe turns. It helps us control the speed and strength of the lathe. A higher ratio makes the lathe spin faster. This is important for different jobs we want to do. How does a metal lathe work? A metal lathe shapes metal by spinning it quickly. As it spins, we use tools to cut the metal. This helps us make different shapes or pieces. It’s like carving, but using a machine! What is a foot brake used for? A foot brake is a pedal we press with our foot. It helps stop the lathe quickly and safely when we need to. This helps us stay safe while we work. Why is the lathe gear ratio important? The lathe gear ratio is important because it affects how the lathe works. It helps us pick the right speed for our project. Choosing the right ratio makes our work easier and better. Can I change the gear ratio on a lathe? Yes, you can change the gear ratio on some lathes. This helps you adjust the speed and strength needed for each job. You just need to follow the instructions carefully to do it right.

Of course! Please share the question you’d like me to answer, and I’ll keep it simple and clear for you.

How Does The Gear Ratio In A Metal Lathe Affect The Operational Speed And Torque Of The Lathe Spindle?The gear ratio in a metal lathe helps control how fast the spindle turns and how much force it has. A higher gear ratio means the spindle spins faster but has less power. A lower gear ratio means it spins slower but has more power to cut through tough metal. So, choosing the right gear ratio helps you do different jobs better.

What Are The Common Gear Ratios Used In Metal Lathes, And How Do They Impact Machining Precision?Common gear ratios in metal lathes include 2:1, 3:1, and 4:1. These numbers show how fast the machine turns compared to the workpiece. A higher ratio helps you cut metal more precisely. So, if you use the right gear ratio, you can get better results in your projects.

How Can A Foot Brake Be Integrated Into A Metal Lathe’S Design For Improved Safety And Ease Of Operation?A foot brake can be added to a metal lathe to make it safer and easier to use. You can press the brake with your foot to stop the machine quickly. This lets you keep your hands free to work. The brake can be connected to the machine’s motor to turn it off instantly. This way, you can be safer while working and finish your tasks faster.

What Maintenance Practices Should Be Followed To Ensure The Smooth Operation Of The Gear Mechanism In A Metal Lathe?To keep the gear mechanism in a metal lathe working well, you should check the parts often. Clean any dirt or debris that can get stuck. You should also oil the gears regularly to keep them moving smoothly. Make sure there are no loose screws or bolts. Lastly, look for any signs of damage and fix them quickly.

How Do Different Gear Ratios Influence The Cutting Performance And Tool Life During Metal Machining Operations On A Lathe?Different gear ratios change how fast the lathe spins the metal. If you use a higher gear ratio, the lathe spins faster, which can cut quickly. But it might wear out the tool faster too. A lower gear ratio makes it cut slower, but this can help the tool last longer. So, you must choose the right gear ratio to balance speed and tool life!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio, Metal Lathe, And Foot Brake:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “What is a lathe gear ratio? A lathe gear ratio tells us how fast the lathe turns. It helps us control the speed and strength of the lathe. A higher ratio makes the lathe spin faster. This is important for different jobs we want to do. How does a metal lathe work? A metal lathe shapes metal by spinning it quickly. As it spins, we use tools to cut the metal. This helps us make different shapes or pieces. It’s like carving, but using a machine! What is a foot brake used for? A foot brake is a pedal we press with our foot. It helps stop the lathe quickly and safely when we need to. This helps us stay safe while we work. Why is the lathe gear ratio important? The lathe gear ratio is important because it affects how the lathe works. It helps us pick the right speed for our project. Choosing the right ratio makes our work easier and better. Can I change the gear ratio on a lathe? Yes, you can change the gear ratio on some lathes. This helps you adjust the speed and strength needed for each job. You just need to follow the instructions carefully to do it right.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please share the question you’d like me to answer, and I’ll keep it simple and clear for you.”}},{“@type”: “Question”,”name”: “How Does The Gear Ratio In A Metal Lathe Affect The Operational Speed And Torque Of The Lathe Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio in a metal lathe helps control how fast the spindle turns and how much force it has. A higher gear ratio means the spindle spins faster but has less power. A lower gear ratio means it spins slower but has more power to cut through tough metal. So, choosing the right gear ratio helps you do different jobs better.”}},{“@type”: “Question”,”name”: “What Are The Common Gear Ratios Used In Metal Lathes, And How Do They Impact Machining Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common gear ratios in metal lathes include 2:1, 3:1, and 4:1. These numbers show how fast the machine turns compared to the workpiece. A higher ratio helps you cut metal more precisely. So, if you use the right gear ratio, you can get better results in your projects.”}},{“@type”: “Question”,”name”: “How Can A Foot Brake Be Integrated Into A Metal Lathe’S Design For Improved Safety And Ease Of Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A foot brake can be added to a metal lathe to make it safer and easier to use. You can press the brake with your foot to stop the machine quickly. This lets you keep your hands free to work. The brake can be connected to the machine’s motor to turn it off instantly. This way, you can be safer while working and finish your tasks faster.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Smooth Operation Of The Gear Mechanism In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the gear mechanism in a metal lathe working well, you should check the parts often. Clean any dirt or debris that can get stuck. You should also oil the gears regularly to keep them moving smoothly. Make sure there are no loose screws or bolts. Lastly, look for any signs of damage and fix them quickly.”}},{“@type”: “Question”,”name”: “How Do Different Gear Ratios Influence The Cutting Performance And Tool Life During Metal Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different gear ratios change how fast the lathe spins the metal. If you use a higher gear ratio, the lathe spins faster, which can cut quickly. But it might wear out the tool faster too. A lower gear ratio makes it cut slower, but this can help the tool last longer. So, you must choose the right gear ratio to balance speed and tool life!”}}]}