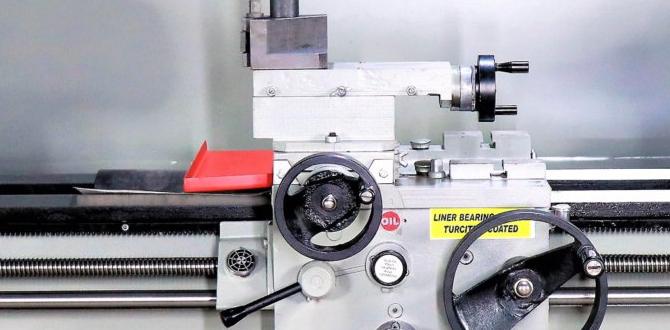

Have you ever watched a metal lathe in action? It’s fascinating to see how it shapes metal into precise parts. But did you know that the lathe gear ratio plays a big role in this process? Understanding this concept can help you get better results from your projects.

Imagine turning a simple piece of metal into a perfect cylinder. You want the lathe to work smoothly. That’s where the right gear ratio comes in. It helps control the handwheel’s movement. This means you can adjust how fast or slow the machine cuts. Isn’t that cool?

Some might wonder why the gear ratio matters so much. The truth is, it can make a big difference in accuracy. A good gear ratio allows for better control. It helps you create smooth finishes and precise shapes.

In this article, we’ll explore why the lathe gear ratio is so important. We’ll look at how the handwheel connects to the gear system and what that means for your metalwork. Get ready to discover tips that can improve your skills!

Understanding Lathe Gear Ratio For Metal Lathe Handwheel Mechanics

Understanding Lathe Gear Ratio for Metal Lathe Handwheel

Lathe gear ratio is crucial for your metal lathe’s performance. It helps control the speed and torque of the machine. Have you ever wondered why some lathes work faster than others? The gear ratio plays a big part in that! A higher ratio means more precision and slower speeds, ideal for fine work. In contrast, a lower ratio offers faster speeds, which is great for rough cuts. Knowing your lathe gear ratio can greatly impact your projects, making your work easier and more efficient.What is Lathe Gear Ratio?

Definition and importance in lathe operations. Explanation of how gear ratio impacts machining speed and torque.A lathe gear ratio shows how the gears in a lathe machine work together. It is important because it affects machining. A correct gear ratio can change the speed and power of the machine. Higher gear ratios mean faster speeds but less torque. Lower ratios provide more torque but less speed. This balance helps machinists choose the right setting for their tasks, ensuring quality work.

How does lathe gear ratio affect machining?

The gear ratio affects both speed and torque. It determines how quickly the metal spins and how much force it uses. Faster speeds mean quicker projects, while more torque helps cut through tougher materials.

- High Gear Ratio: Faster but less force.

- Low Gear Ratio: More force but slower.

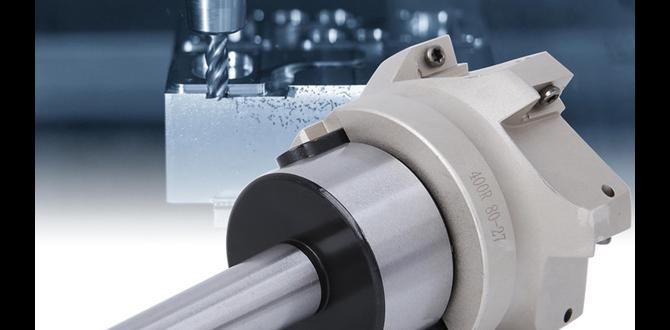

Components of a Metal Lathe Gear System

Description of key components like the headstock, gears, and handwheel. Functionality of each component in relation to gear ratio.A metal lathe gear system has a few key parts that help it work well. First, there’s the headstock, which holds the motor and provides power. Next are the gears, which control the speed and direction of the lathe. Lastly, the handwheel lets users adjust the cutting tool easily.

Each part is important for the gear ratio:

- Headstock: It powers the lathe.

- Gears: They change speeds and force during cutting.

- Handwheel: It controls the depth and position.

These components work together to create smooth and precise movements, making the metal lathe a fantastic tool for shaping materials.

What does a metal lathe do?

A metal lathe shapes materials into precise pieces. It spins the material while a cutting tool removes extra bits, creating the desired shape.

Key Functions of Parts:

- Headstock: The driving force.

- Gears: Adjust speed and torque.

- Handwheel: For fine adjustments.

How to Calculate Lathe Gear Ratio

Stepbystep guide to measuring and calculating gear ratio. Examples for common lathe setups.Calculating the lathe gear ratio is simple. Here’s a step-by-step guide.

- First, check the number of teeth on the drive gear.

- Next, find the number of teeth on the spindle gear.

- Now, use this formula: Gear Ratio = Drive Gear Teeth / Spindle Gear Teeth.

For example, if the drive gear has 20 teeth and the spindle gear has 10 teeth, the gear ratio is 2:1. This means that for every two turns of the drive gear, the spindle makes one full turn. Many lathes use common setups like 1:1 or 2:1 for various tasks.

What is a lathe gear ratio?

The lathe gear ratio determines how fast the spindle turns compared to the drive gear. A higher gear ratio makes the spindle turn slower with more torque, while a lower gear ratio increases speed with less strength.

Impact of Gear Ratio on Lathe Performance

How gear ratio affects cutting speed and precision. Pros and cons of varying gear ratios in different machining tasks.The gear ratio plays a big role in how well a lathe cuts. A higher gear ratio means faster cutting speeds, making tasks quicker. However, it may reduce precision, like trying to draw a straight line while running! Balancing speed and accuracy is key.

Different jobs might need different gear ratios. For heavy metal, a low ratio gives more control, whereas delicate work might prefer a high ratio for speed. Here’s a handy table to show how gear ratios help:

| Gear Ratio | Cutting Speed | Precision |

|---|---|---|

| High | Fast | Lower |

| Low | Slow | Higher |

In the world of lathes, gear ratio is like that friend who knows when to speed up or slow down. Choose wisely!

Adjusting Gear Ratios on Metal Lathes

Techniques for modifying gear ratios. Best practices for changing gears safely and effectively.Changing gear ratios on metal lathes can seem tricky, but it’s easier than pie! First, always make sure you follow best practices for safety. Turn off the lathe and wear protective gear. Next, check your machine’s manual. It’s like having a treasure map for your lathe. When altering gears, ensure they fit snugly. An improperly fitted gear can lead to chaos, like a dancing elephant in a china shop! Always double-check your adjustments before using the lathe.

| Technique | Best Practice |

|---|---|

| Use a gear wrench | Always wear safety goggles |

| Choose compatible gears | Double-check fits |

| Consult the manual | Turn off lathe first |

FAQs about Lathe Gear Ratios and Handwheels

Answer common queries regarding gear ratio adjustments and handwheel functionality. Provide troubleshooting tips for gear issues.Many people have questions about gear ratios and handwheels. Here are some common queries and their answers:

What is a lathe gear ratio?

A lathe gear ratio is the relationship between the rotation of the motor and the rotation of the workpiece. This affects how fast materials are shaped.

How do I adjust the gear ratio?

- Locate the gear adjustment handle.

- Turn it to change the ratio.

- Check the settings on the display.

What if my handwheel is stuck?

If the handwheel won’t turn, check for debris or rust. Clean it gently with oil or lubricant.

What are some signs of gear issues?

- Unusual noises while operating.

- Difficulty changing speeds.

- Inconsistent material shaping.

Conclusion

In conclusion, understanding the lathe gear ratio helps you control your metal lathe better. You can adjust the handwheel for more precise movements. This knowledge makes your projects easier and more accurate. So, next time you work on a lathe, remember these tips. Check out more resources online to keep learning and improve your skills!FAQs

What Is The Purpose Of The Gear Ratio In A Metal Lathe’S Handwheel, And How Does It Affect Precision During Machining?The gear ratio in a metal lathe’s handwheel helps you control how much the tool moves. It makes it easier to turn the handwheel. With the right gear ratio, you can move the tool slowly and carefully. This means you can make more precise cuts, which helps you create better and smoother shapes in metal.

How Can A Lathe Operator Calculate The Appropriate Gear Ratio For Different Machining Tasks On A Metal Lathe?To calculate the right gear ratio for a metal lathe, you need to know a few things. First, look at the speed you want for your job. Then check the speed your lathe can run. Divide the desired speed by the lathe speed to find the gear ratio. This tells you how many times the lathe turns for each turn of the gear. Adjust the gears until you get the right number for your task!

What Are The Common Gear Ratios Used In Metal Lathe Handwheels, And How Do They Influence The Movement Of The Carriage And Cross-Slide?Common gear ratios for metal lathe handwheels are often around 4:1 or 10:1. This means that for every turn of the wheel, the carriage or cross-slide moves four or ten times as much. Higher ratios make the machine move farther with less effort. Lower ratios give you more control, but require more turns. This helps us do different tasks easily.

What Are The Potential Challenges Or Issues That May Arise From Improper Gear Ratio Settings On A Metal Lathe?If the gear ratios on a metal lathe are set wrong, it can cause problems. You might have a hard time cutting the metal smoothly. The tool could move too fast or too slow, making messy parts. It could also wear out the machine faster. Too much strain might even break the lathe, which would be very costly to fix.

How Does The Gear Ratio In The Handwheel Impact The Feed Rate And Surface Finish Of The Final Machined Part?The gear ratio in the handwheel controls how fast you move the machine. A higher gear ratio means you turn the wheel more times, but the machine moves less. This can make the feed rate slower, which helps to create a smoother surface. If you use a lower gear ratio, the machine moves faster, but the surface might not be as nice. So, the gear ratio helps balance speed and quality.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of The Gear Ratio In A Metal Lathe’S Handwheel, And How Does It Affect Precision During Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio in a metal lathe’s handwheel helps you control how much the tool moves. It makes it easier to turn the handwheel. With the right gear ratio, you can move the tool slowly and carefully. This means you can make more precise cuts, which helps you create better and smoother shapes in metal.”}},{“@type”: “Question”,”name”: “How Can A Lathe Operator Calculate The Appropriate Gear Ratio For Different Machining Tasks On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate the right gear ratio for a metal lathe, you need to know a few things. First, look at the speed you want for your job. Then check the speed your lathe can run. Divide the desired speed by the lathe speed to find the gear ratio. This tells you how many times the lathe turns for each turn of the gear. Adjust the gears until you get the right number for your task!”}},{“@type”: “Question”,”name”: “What Are The Common Gear Ratios Used In Metal Lathe Handwheels, And How Do They Influence The Movement Of The Carriage And Cross-Slide? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common gear ratios for metal lathe handwheels are often around 4:1 or 10:1. This means that for every turn of the wheel, the carriage or cross-slide moves four or ten times as much. Higher ratios make the machine move farther with less effort. Lower ratios give you more control, but require more turns. This helps us do different tasks easily.”}},{“@type”: “Question”,”name”: “What Are The Potential Challenges Or Issues That May Arise From Improper Gear Ratio Settings On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the gear ratios on a metal lathe are set wrong, it can cause problems. You might have a hard time cutting the metal smoothly. The tool could move too fast or too slow, making messy parts. It could also wear out the machine faster. Too much strain might even break the lathe, which would be very costly to fix.”}},{“@type”: “Question”,”name”: “How Does The Gear Ratio In The Handwheel Impact The Feed Rate And Surface Finish Of The Final Machined Part? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio in the handwheel controls how fast you move the machine. A higher gear ratio means you turn the wheel more times, but the machine moves less. This can make the feed rate slower, which helps to create a smoother surface. If you use a lower gear ratio, the machine moves faster, but the surface might not be as nice. So, the gear ratio helps balance speed and quality.”}}]}