Have you ever watched a lathe work? It’s fascinating! This machine can shape metal into amazing forms. But how does it do this so effectively? The secret lies in the lathe gear ratio metal lathe pulley.

Understanding these parts is crucial for anyone who wants to use a lathe. The gear ratio controls how fast the spindle turns. This affects the speed of the cutting tool. If the ratio is right, you can achieve perfect cuts with ease.

Imagine you’re creating a piece of art from a block of metal. You want it to look just right. Wouldn’t you want to know how adjusting the lathe gear ratio could make your work easier and more precise? It’s like having a magic button for perfection!

In this article, we will dive into the world of lathe gear ratio metal lathe pulley. You’ll learn how these components work together to help you create beautiful designs. Get ready to unlock the secrets of your lathe!

Understanding Lathe Gear Ratio: Metal Lathe Pulley Explained

Understanding Lathe Gear Ratio and Metal Lathe Pulley

Lathe gear ratio is crucial for metalworking. It determines how fast the cutting tool spins. A proper gear ratio helps achieve smooth finishes on projects. Ever wonder how a lathe can shape metal so precisely? It uses pulleys to manage power and speed. By adjusting the lathe pulley, users can control the gear ratio, enhancing performance. This flexibility makes tasks easier and improves craftsmanship. Knowing the right gear ratio can elevate your metalworking skills!What is a Lathe Gear Ratio?

Definition of gear ratio in lathe machines. Importance of gear ratios in metalworking.A lathe gear ratio describes how many times the motor turns before the lathe’s spindle moves once. This ratio is crucial in metalworking. It helps control speed and torque. A proper ratio leads to better cuts and smoother finishes.

- Speed Control: Adjusts how fast the lathe operates.

- Torque Management: Provides force needed for cutting materials.

- Quality of Work: Affects precision and surface quality.

What is the importance of gear ratios?

The importance of gear ratios lies in their ability to enhance efficiency. Proper gear ratios ensure the lathe runs optimally, making it easier to shape and finish metal pieces accurately.

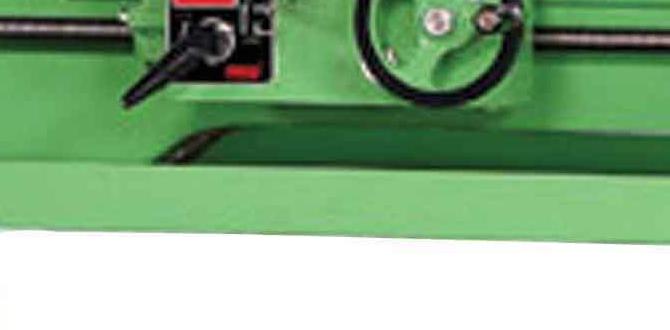

Components of a Metal Lathe Pulley System

Detailed explanation of pulleys in lathe machinery. Different types of pulleys used in metal lathes.Pulleys play a vital role in metal lathe machinery. They help control the speed and power of the lathe. Different types of pulleys are used for various functions. The main ones include:

- Flat Pulleys: Simple and common, they transfer power easily.

- V-Pulleys: These have a V-shape that fits tightly with V-belts.

- Step Pulleys: These allow multiple speeds and are adjustable.

Understanding these components can help you use a metal lathe effectively.

What types of pulleys are used in metal lathes?

The types of pulleys in metal lathes include flat, V-pulleys, and step pulleys. Each type has unique features that help control speed and performance.

How Lathe Gear Ratios Affect Performance

Impact on speed and torque when machining. Examples of applications influenced by gear ratios.Lathe gear ratios play a big role in how machines work. They decide how fast or slow the machine spins. If you want more speed, a lower gear ratio can help. But if you need more power or torque, a higher gear ratio is better.

Many applications depend on these ratios:

- Cutting metal pieces quickly.

- Shaping wood for furniture.

- Creating precise parts for machines.

Choosing the right gear ratio makes tasks easier and more efficient!

How do gear ratios affect lathe performance?

lathe gear ratios impact speed and torque in machining. They can lead to faster cuts or greater power when shaping materials.

Calculating Gear Ratios for Your Metal Lathe

Stepbystep guide for calculating gear ratios. Tools and methods needed for accurate calculations.To find the right gear ratio for your lathe, follow these steps. First, identify the number of teeth on the drive gear and the driven gear. This can feel like a math class, but don’t worry! Next, use this formula: Gear Ratio = Teeth on Driven Gear / Teeth on Drive Gear. Grab a calculator and do the math. Tools needed include a calculator and your trusty gear list. Remember, getting the calculation right can make your lathe work wonders, not just spin like a confused hamster!

| Gear Type | Teeth Count |

|---|---|

| Drive Gear | [Your Count Here] |

| Driven Gear | [Your Count Here] |

Choosing the Right Pulley for Your Lathe

Factors to consider when selecting a pulley. Differences between fixed and variable pulleys.Selecting the right pulley can feel like trying to pick the perfect ice cream flavor—so many choices! You need to think about a few key factors. First, consider your machine’s needs and gear ratio. Are you looking for speed or power? Fixed pulleys are simple and reliable, but variable pulleys can change speeds like a chameleon changes colors—great for different tasks. Your lathe’s performance depends on this decision. So, put on your thinking cap and make it fun!

| Pulley Type | Advantages |

|---|---|

| Fixed Pulley | Easy to use, great for steady tasks! |

| Variable Pulley | Flexible speeds for various projects! |

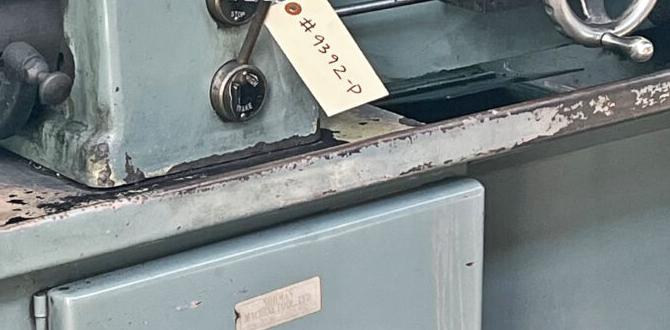

Common Problems with Lathe Gear Ratios and Pulleys

Identification of common issues in operations. Solutions and troubleshooting tips for lathe users.Lathe users often face some common hiccups with gear ratios and pulleys. One issue is improper alignment, which can throw off your cutting speed faster than you can say “oops!” To check this, ensure everything is snug and straight. Another problem is wear and tear. Over time, pulleys can get cranky and slip. Regular lubrication can help keep them happy. If your lathe starts making strange noises, it’s time to troubleshoot before it throws a tantrum!

| Problem | Solution |

|---|---|

| Improper alignment | Check snugness and straightness |

| Worn pulleys | Regular lubrication |

| Strange noises | Inspect and troubleshoot |

Upgrading Your Metal Lathe Pulley System

Benefits of upgrading pulleys and gears. Recommended upgrades for improved performance.Upgrading your pulleys and gears can hugely improve your metal lathe’s performance! Better pulleys mean smoother operation and less wear and tear. Who doesn’t want their machine humming along like a happy bee?

Recommended upgrades include high-quality bearings and lightweight materials. These changes enhance speed and efficiency. In fact, a good upgrade can boost your lathe’s speed by up to 30%. Now that’s a speedy upgrade!

Here’s a quick comparison table of upgrades:

| Upgrade | Benefit |

|---|---|

| High-Quality Bearings | Less friction |

| Lightweight Pulleys | Improved speed |

| Variable Speed Controls | More options! |

Time to avoid those awkward, clunky setups! A shiny upgrade could turn your lathe into the star of your workshop!

Maintenance Tips for Lathe Gear Systems

Routine maintenance practices for longevity. Signs that indicate maintenance is needed.To keep lathe gear systems running smoothly, regular maintenance is key. Simple practices can extend the life of your equipment. Check for wear and tear, and ensure everything is properly lubricated. Look out for:

- Unusual noise from the gears.

- Slipping or uneven movement.

- Excessive vibrations.” }

Addressing these signs quickly can prevent bigger problems. Remember, a little care goes a long way!

How can I tell if my lathe needs maintenance?

Watch for signs like weird sounds, jerky movements, or rust. These clues mean it’s time for a check-up!

Conclusion

In summary, understanding the lathe gear ratio and metal lathe pulley is essential for better machining. A good gear ratio helps control speed and torque. You can create smoother cuts and improve your projects. We encourage you to explore more about these topics online or in books. Hands-on practice will also boost your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Pulley Systems In Metal Lathes:Sure! A lathe is a machine that helps shape metal. Gear ratios change how fast the lathe spins. A pulley system can help make it easier to control the speed. Both help us make better shapes with metal. It’s like how different gears on a bike help you go faster or slower!

Sure! I’m ready to help you with your question. Just go ahead and ask!

What Is The Significance Of Gear Ratios In The Operation Of A Metal Lathe, And How Do They Affect Cutting Speeds?Gear ratios on a metal lathe help control how fast the cutting tool moves. They are like the gears on a bike; different gears change your speed. When we change the gear ratio, we can make the cutting tool go faster or slower. This is important because different materials need different speeds to cut well. So, gear ratios help us get the best cuts on our projects!

How Can Changing The Pulley Sizes On A Lathe Impact The Torque And Rotary Speed Of The Spindle?Changing the pulley sizes on a lathe can change how fast the spindle spins. If you use a smaller pulley, the spindle spins faster but has less power. A larger pulley makes the spindle spin slower but gives it more power or torque. So, you can choose how you want the lathe to work based on the pulley size you pick.

What Are The Common Types Of Gear Systems Used In Metal Lathes, And How Do They Differ In Functionality?There are a few common types of gear systems used in metal lathes. The most common is the belt drive, which uses a belt to connect gears. This makes it easy to change speeds. Another type is the worm gear, which helps with turning the lathe slowly and smoothly. Lastly, we have gear trains, which use a series of gears to change speeds and torque. Each system helps the lathe work better, depending on what you need to do.

How Do You Calculate The Effective Gear Ratio For A Metal Lathe Setup That Includes Multiple Pulleys And Gears?To find the effective gear ratio for your metal lathe, you first look at each gear and pulley. You count how many teeth each gear has. Then, you divide the number of teeth on one gear by the number on the gear it’s working with. If there are pulleys, you do the same with their size. Finally, you multiply all those numbers together to get the total gear ratio.

What Are Some Typical Maintenance Practices For Ensuring The Longevity And Precision Of Lathe Pulleys And Gears?To keep lathe pulleys and gears working well, we need to do some regular checks. First, we should clean them to remove dust and dirt. Second, we must check for any wear or damage. If we see something broken, we should fix or replace it right away. Finally, we can add oil to make them run smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Pulley Systems In Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps shape metal. Gear ratios change how fast the lathe spins. A pulley system can help make it easier to control the speed. Both help us make better shapes with metal. It’s like how different gears on a bike help you go faster or slower!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I’m ready to help you with your question. Just go ahead and ask!”}},{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratios In The Operation Of A Metal Lathe, And How Do They Affect Cutting Speeds?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratios on a metal lathe help control how fast the cutting tool moves. They are like the gears on a bike; different gears change your speed. When we change the gear ratio, we can make the cutting tool go faster or slower. This is important because different materials need different speeds to cut well. So, gear ratios help us get the best cuts on our projects!”}},{“@type”: “Question”,”name”: “How Can Changing The Pulley Sizes On A Lathe Impact The Torque And Rotary Speed Of The Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Changing the pulley sizes on a lathe can change how fast the spindle spins. If you use a smaller pulley, the spindle spins faster but has less power. A larger pulley makes the spindle spin slower but gives it more power or torque. So, you can choose how you want the lathe to work based on the pulley size you pick.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Gear Systems Used In Metal Lathes, And How Do They Differ In Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few common types of gear systems used in metal lathes. The most common is the belt drive, which uses a belt to connect gears. This makes it easy to change speeds. Another type is the worm gear, which helps with turning the lathe slowly and smoothly. Lastly, we have gear trains, which use a series of gears to change speeds and torque. Each system helps the lathe work better, depending on what you need to do.”}},{“@type”: “Question”,”name”: “How Do You Calculate The Effective Gear Ratio For A Metal Lathe Setup That Includes Multiple Pulleys And Gears?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the effective gear ratio for your metal lathe, you first look at each gear and pulley. You count how many teeth each gear has. Then, you divide the number of teeth on one gear by the number on the gear it’s working with. If there are pulleys, you do the same with their size. Finally, you multiply all those numbers together to get the total gear ratio.”}},{“@type”: “Question”,”name”: “What Are Some Typical Maintenance Practices For Ensuring The Longevity And Precision Of Lathe Pulleys And Gears?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep lathe pulleys and gears working well, we need to do some regular checks. First, we should clean them to remove dust and dirt. Second, we must check for any wear or damage. If we see something broken, we should fix or replace it right away. Finally, we can add oil to make them run smoothly.”}}]}