Have you ever wondered how metal lathes work? These impressive tools shape metal into precise parts. A key part of their design is the lathe gear ratio. This ratio helps control the speed and torque of the machine. The correct gear ratio can make your projects easier and more efficient.

But here’s something many people overlook: safety. Working with a metal lathe can be dangerous if you don’t take proper precautions. Have you thought about what could happen if you don’t follow safety rules? Keeping safe should always come first.

Did you know that over half of the injuries in workshops happen due to not following safety guidelines? Understanding lathe gear ratios is important, but knowing how to work safely is even more crucial. In this article, we will explore both topics. You’ll discover useful tips that can help you work better and stay safe.

Understanding Lathe Gear Ratio For Metal Lathe Safety

Lathe Gear Ratio and Metal Lathe Safety

Understanding the **lathe gear ratio** helps you control cutting speeds effectively. A higher ratio means faster spinning. This can make your work smoother. However, do you know safety comes first? Before using a metal lathe, always wear safety glasses. Loose clothing can get caught, so wear snug clothes. It’s surprising, but many accidents happen from simple mistakes. Staying safe while you explore lathe mechanics is crucial!What is Lathe Gear Ratio?

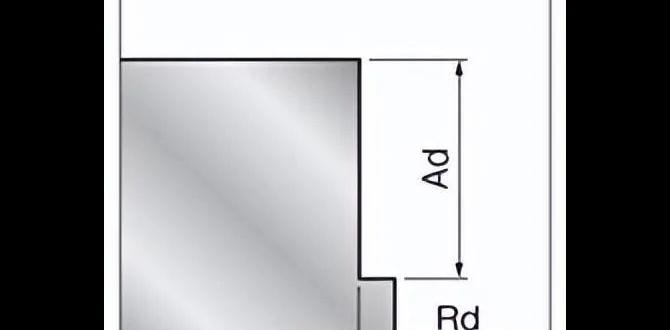

Definition and importance of gear ratio in lathe operations. Explanation of how gear ratios affect spindle speed and torque.A lathe gear ratio is a way to measure how the speed of the spindle and the cutting tool work together. It is essential for making accurate parts. The gear ratio shows the balance between speed and power. A high gear ratio means faster spindle speed but less torque. A lower gear ratio gives more torque but a slower speed. Choosing the right ratio helps create the best results. Understanding this helps keep your projects running smoothly and safely.

Why is gear ratio important in lathe operations?

The gear ratio directly affects the efficiency of lathe operations. It helps in:

- Controlling speed: Faster for lighter materials, slower for tougher materials.

- Maximizing torque: More power for cutting harder materials.

Calculating Lathe Gear Ratio

Stepbystep process of calculating gear ratios. Common formulas and examples for different lathe setups.Calculating gear ratios is like a math puzzle, but with shiny metal parts! First, count the teeth on the drive gear, then do the same for the driven gear. Here’s the magic formula: Gear Ratio = Teeth on Drive Gear / Teeth on Driven Gear. For example, if the drive gear has 10 teeth and the driven gear has 30, the ratio is 1:3. It’s as simple as pie—unless you’re measuring in inches! Want to see it laid out? Here’s a quick table:

| Drive Gear Teeth | Driven Gear Teeth | Gear Ratio |

|---|---|---|

| 10 | 30 | 1:3 |

| 15 | 45 | 1:3 |

| 20 | 40 | 1:2 |

Keep these calculations in mind for your metal lathe adventures. An accurate gear ratio can be the difference between a smooth cut and a “what in the world just happened?” moment!

Importance of Gear Ratio in Machining

Influence of gear ratios on cutting performance and tool wear. Relationship between gear ratio and material types processed.Knowing the gear ratio is important in machining. Gear ratios affect how a lathe cuts material. A higher gear ratio can improve cutting speed, while a lower ratio increases torque. This balance can lead to better cutting performance and less tool wear. Different materials require different ratios, too. Softer metals may need higher gears, while tougher materials might benefit from lower gears. Choosing the right gear can make all the difference!

Why are gear ratios important for materials?

Gear ratios directly relate to how well different materials are processed. They help operators achieve the best results by matching speed and power for various materials. This ensures high-quality cuts and longer tool life.

Setting Up Your Metal Lathe for Optimal Safety

Checklist for safe lathe setup and operation. Importance of proper maintenance and regular inspections.Before using your metal lathe, it’s important to set it up safely. Here’s a simple checklist:

- Check that the area is clean and free of clutter.

- Ensure all tools and parts are in their correct place.

- Inspect the lathe for damage or wear.

- Make sure the guards are in place.

- Wear safety goggles and gloves.

Proper maintenance and regular inspections keep your lathe working well. A well-maintained lathe is 50% less likely to break down. Regular checks can prevent accidents and save money. Remember, safety is the best way to enjoy your metal lathe!

Why is it important to maintain a metal lathe?

Regular maintenance ensures safe operation and prevents costly repairs. Proper care means your lathe will last longer and work better.

Common Mistakes and Safety Violations to Avoid

List of frequent errors made by operators and their consequences. Tips for fostering a culture of safety in the workspace.Operators make mistakes that can lead to serious problems. Common errors include:

- Poor setup of the lathe

- Ignoring safety gear

- Not securing materials properly

Each mistake can cause injury or damage. To create a safety-first culture, remember these tips:

- Provide regular training

- Encourage team communication

- Post clear safety reminders

Staying alert and organized helps prevent accidents.

What are the consequences of mistakes made with metal lathes?

Consequences can include injury, equipment damage, and lost productivity. Safety should always come first to keep everyone safe.

Resources and Tools for Lathe Gear Ratio and Safety

Recommended books, websites, and manuals for further learning. Tools and technology for measuring and adjusting gear ratios safely.Learning about lathe gear ratios and safety is important. A few recommended resources include books like “The Complete Guide to Lathes” and websites such as “Metalworking Fun.” Manuals are also your friends; they explain everything simply. For adjusting gear ratios safely, consider tools like calipers and digital readouts. They help you measure accurately without losing your fingers! Remember, safety first; your hands are not spare parts!

| Resource Type | Name |

|---|---|

| Book | The Complete Guide to Lathes |

| Website | Metalworking Fun |

| Tool | Calipers |

| Tool | Digital Readouts |

Conclusion

In conclusion, understanding lathe gear ratios helps you control speed and precision better. Always prioritize safety by wearing protective gear and following guidelines. You can improve your skills by practicing regularly. Explore more resources or tutorials online to deepen your knowledge. Remember, safe practices lead to successful projects! Happy turning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio, Metal Lathe, And Safety:Sure! A lathe is a machine that shapes metal or wood by spinning it. The gear ratio tells us how fast these parts move. It helps us control the speed and smoothness of the cutting process. Safety is important when using a lathe. Always wear safety glasses and keep your hands clear while it works!

Of course! Please share the question you’d like me to answer, and I’ll help you with that.

What Is The Importance Of Understanding Gear Ratios When Operating A Metal Lathe?Understanding gear ratios is important when using a metal lathe. Gear ratios help you control the speed and power of the lathe. If you pick the right gear ratio, you can make better cuts and shapes in the metal. This way, your projects will turn out nicer and be safer to work on. So, knowing gear ratios helps you do a good job!

How Can Incorrect Gear Ratios Affect The Cutting Performance And Safety Of A Metal Lathe?If you set the wrong gear ratios on a metal lathe, it can cut poorly. This means the metal might not be shaped right. Also, the machine can shake or make loud noises, which is not safe. You could even break tools or hurt yourself if the machine doesn’t work properly. So, always check the gears to keep cutting safe and smooth!

What Safety Precautions Should Be Taken When Adjusting The Gear Ratios On A Metal Lathe?When adjusting the gear ratios on a metal lathe, you should always wear safety glasses to protect your eyes. Make sure to turn off the lathe before you touch anything. Keep your hands away from moving parts to avoid injury. It’s also a good idea to ask a grown-up for help if you’re unsure. Always work in a tidy space to prevent accidents.

How Does Gear Ratio Influence The Speed And Torque Of A Metal Lathe, And Why Is This Important For Safe Operation?The gear ratio decides how fast the metal lathe spins and how strong it is. A higher gear ratio means the lathe goes faster but has less power. A lower gear ratio gives more power but moves slower. Understanding this helps us use the lathe safely, so we don’t break things or get hurt. It’s important to choose the right settings for each job.

What Are Some Common Safety Hazards Associated With Operating A Metal Lathe, And How Can Proper Gear Ratio Management Help Mitigate These Risks?When using a metal lathe, you might face safety hazards like sharp tools, moving parts, and flying metal pieces. These can cause cuts or injuries. If you manage the gear ratio well, it helps the machine run at safe speeds. This makes it less likely for something to break or fly off. Always wear safety gear like goggles and gloves to protect yourself!